Technology and Innovations: Elevator Inspector Speaks to Universities

Apr 1, 2011

by Susan Davey

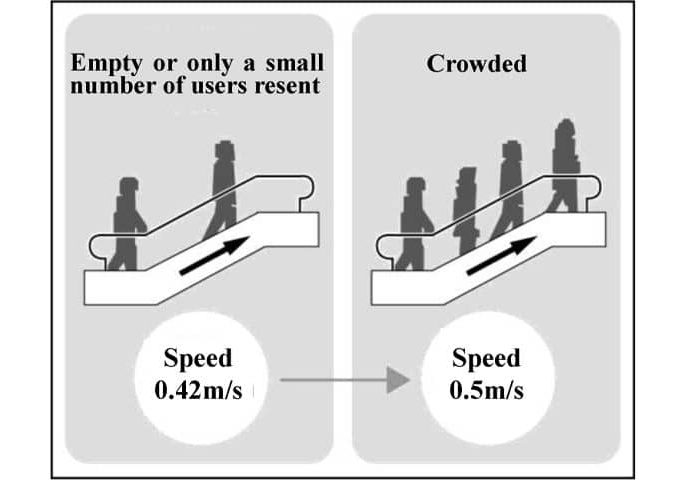

The elevator business is truly a big business. Public-use elevators literally line the globe from the U.S. to Australia, China, the U.A.E., India, Africa and Europe. Technology is moving so quickly today that building owners and the general public can quickly find themselves left behind. This is particularly true with elevators and lift devices, where electronics abound and new materials silently make their way into our everyday lives. During a recent trip through the airports of Austin, Texas, Chicago and Washington D.C., I became aware of the untold number of elevators, escalators, moving walkways and lift devices as they silently shuffled each of us and our belongings flawlessly from spot to spot. Many of these machines are state-of-the-art, and bring much to the design integrity of the buildings they serve.

The latest designs in elevator equipment featuring new cutting-edge mechanical devices are usually available to brave companies wishing to give them a try at a sizeable discount from manufacturers wishing to break into new markets, or interested in adding new equipment to their offerings. These new inventions are generally comprised of proprietary equipment. The purchaser has historically been denied access to the necessary tools needed for repair by the sellers, leaving purchasers to pay higher prices than normal for routine upkeep and maintenance of the new equipment. In my role as a university administrator, I have become aware of a quandary: at public universities we educate engineers, architects and designers, but when it comes to actually purchasing, installing and using this beautifully designed equipment created by those we have educated, we find our hands to be tied because of safety and cost concerns. One large university in Texas installed five “new technology” elevators several years ago, and when similar equipment in an un-related location became unsafe, the state compelled the university to increase their inspections of the elevators until the elevators could be replaced. The elevators were replaced without question by the original installer at no charge to that university. However, having those five elevators out of service for replacement was an extreme inconvenience to the students, faculty and staff at the institution. Similar occurrences at smaller education institutions where the sting felt by out of service equipment would be more acute because of possible shortages of alternative Americans with Disabilities Act (ADA) accessible classroom space could wield a devastating blow to the education of handicapped students is unacceptable.

At state run universities, the monies we spend come from the public funds; to the public servants in Texas, these dollars have a high value as they have been entrusted to us by the taxpayer. Administrators at public institutions across our nation realize they must carefully make the best use of every cent of the public’s money. There is no room in today’s tight budgets that are being cut to the bone for purchasing equipment that may have a planned obsolescence or lifetime that is shorter than existing conventional equipment, or for equipment that could possibly become unusable because of circumstances relating to the safety of the design or failure of the mechanical equipment.

Can public institutions consider saving money by purchasing the latest wonderful and amazing designs frequently being offered at deeply discounted prices with confidence, or must we forever shy away from modern technology? To answer these and other questions, I went to Lawrence Taylor of the Elevator Division of the Texas Department of Licensing and Regulation (TDLR).

Taylor is the chief elevator inspector for the State of Texas. He has more than 40 years of experience working in the electrical and elevator industry, and is a certified elevator inspector supervisor by all three QEI accredited organizations and is a certified electrical inspector by the International Association of Electrical Inspectors. In addition, Taylor administers the policies established by the Texas Legislature through their adoption of the Texas Health and Safety Code Chapter 754-The Act, the policies of the Commissioners of the Texas Department of Licensing and Regulation (TDLR), and the executive office of the TDLR. Taylor is well respected in the industry for his common sense, honesty, fairness, good will, and his willingness to share his wealth of technical knowledge.

Susan Davey (SD): In universities across our nation, students study technology, engineering and design. Modern technology is inspiring to see and to use. Our students will become leaders in their chosen fields. We want our students to dream of designing and inventing future products; we openly urge them to include new products/technologies in their choices for design. In your opinion, when is it safe for universities, both monetarily and safety-wise, to step into the forefront? How does one know when it is good to embrace new technologies?

Lawrence Taylor (LT): Those are difficult questions to answer. First and foremost, in Texas, no one is allowed to use any technology not permitted within the scope of the currently adopted standard without the department first issuing a new technology variance. That takes away the ability to sell, buy and install whatever the newest fad in technology might be. No one likes new technology and new gizmos more than I do, but I see it as the job of the department to have a healthy skepticism when it comes to new technology and exposing the public to some potentially defective product.

The department is not responsible for helping manufacturers market their products, nor is it to stand unreasonably in the way of progress and the use of new, safe technology. However, our job is people and protecting them, and that often puts regulators at odds with the commercial interest of manufacturers. There have been ample examples of what appears to be a great idea that didn’t work out too well in the real elevator world. I’m not sure who said this but just because you can do something doesn’t mean that you should or that it’s a good application or idea. For me, personally, it all comes down to answering a couple of questions: A) Would I want anyone in my family to be exposed to these products? B) Would

I want to read about my role in approving a product in the Austin American Statesman?

While I am not the sole arbiter of what gets approved in this state, I approach my role in that process with these questions in mind. I sincerely believe that a healthy dose of skepticism on the part of the department serves the public welfare and does not present an undue burden on the use of new technology.

SD: Is there a licensing process these new technologies must pass in order to gain licensure for use by the general public?

LT: Yes. In the State of Texas, no one is allowed to use any technology not permitted within the scope of the currently adopted standard. Prior to the installation of any device, a request for New Technology Variance must

be granted by the department. The applicant provides the department with the requested information, and a committee consisting of the executive director, deputy director, director of Compliance, Building and Mechanical Program manager, General Counsel and myself. We review the materials and come to a consensus. All applications shall contain the following, if applicable:

- An enumeration and description of all the requirements of the adopted standard for which a new technology variance is being requested.

- Documentary evidence to support a claim of equivalence or superiority to the requirements of the adopted standard.

- Documentary evidence that the new technology is being or may be considered by the American Society of Mechanical Engineers (ASME) code committee(s) for inclusion in a future standard.

- An estimated time frame for the approval of the new technology by the ASME code committee(s).

- Any additional supporting evidence deemed necessary by the applicant to assist in making a determination.

- The new technology variance application fees outlined in Section 74.80(h) of the current ASME rules and regulations.

SD: To date, how many applications of this type have been granted?Continued

LT: There have been eight applications, and all have been approved. However, TDLR has attached conditions to each as a part of the approval process.

SD: What can be done to protect the financial investment made by the purchaser of the equipment if it is deemed to be unfit for use at any time during its expected lifetime?

LT: Of course, any purchaser or their consultant may include clauses within their original contract for purchase with the sole purpose of protecting the owner. TDLR cannot make any recommendations in that respect.

SD: Is there any way to purchase proprietary equipment and also have access to the tools needed for repair at a reasonable cost?

LT: This can also be included within any original contract for purchase. TDLR cannot make any recommendations in that respect.

SD: It is my perception that as lift technology continues to develop contracts must also continue to develop, with a higher level of expertise in contracting being expected from contracting professionals.

LT: That is correct.

SD: How and why did you get started in the elevator business?

LT: While in high school I began working as a helper to an electrical engineer who worked on vertical lifts, cantilever lifts and rotating draw bridges and the elevators in them.

Carl Robinson and John Payne, both of Raleigh, North Carolina, were mentors to me and many other generations of young men. Now that I am older than they were when we first met, I can really appreciate the subtle and sometimes not so subtle ways they affected me and many others in the elevator business. These men were mentors in the truest sense of the word and without them and the positive influence they had on my life there is no telling what would have happened to me and where I would be right now. Everyone in the elevator business who has been around for any length of time can tell you stories about mechanics they worked for who wouldn’t let the helper see the drawings or used the helpers as nothing more than mules, never really teaching the helper anything. Carl and John were not those types of people. They would teach me anything I wanted to know and there were no two finer people to teach a young helper about the real elevator world. I thought even back then, that they were two of the smartest men I’d ever met and I still feel that way to this very day. Both Carl and John would answer their home phone at any hour of the night (there were no cell phones back then) and help you troubleshoot something if necessary, and would get out of bed and meet you to help. Tell me, how many people would do that today? I wish we had more men like Carl and John in the industry now. Now, men like these are the exception. The industry is sorely lacking the men and women who are willing and capable of mentoring the industry youth. The mentoring mentality has all but disappeared from the elevator business. It is still out there, but it does not permeate the business like it once did.

SD: What is the best advice you can give to students as they go out into the working world?

LT: I received three pieces of advice in my life which have profoundly affected me, and I want to share them: from my Father, Garland Taylor, who worked on an assembly line for nearly 50 years: “Son, find something to do with your work life that you enjoy. Don’t wind up like me hating to go to work every day,” from Carl Robinson on the first day I reported to work: “You’ll either love or hate the elevator business. If you’re still here in six months you’ll be here for the rest of your life,” and from John Payne: “It’s one thing to know what you know, but even more important to recognize what you don’t know, and being smart enough to not to mess with it without getting some help.”

SD: What new types of technology can you foresee within the next 10 years?

LT: It is inevitable that some new breakthrough will revolutionize vertical transportation, and it will probably be invented by a twenty-something gizmo geek who is in middle school today. I would not be surprised to see the use of super magnets and magnetic levitation made possible during my lifetime.

The information gathered during this short interview has great value for building owners. Now we understand how properly written contracts can be useful in protecting the interests of those we serve. Clauses can be added to documents which may include language written to protect the owner, such as “if all or any portion of this equipment is deemed by any state licensing entity or any authority having jurisdiction, to be unsafe or unusable for any reason during the expected life time (here the expected life time could be stated) relating to design or mechanical make up of the device, it will be removed and replaced with equipment of the owner’s choosing at the expense of the installer.” In addition, if proprietary equipment is purchased by a building owner, it can be stated in the contract “all tools, computers and software shall be included in the purchase price of the equipment, and all future necessary replacements and updates to the tools and diagnostic equipment shall be supplied to the owner free of charge for the lifetime of the device.” The language suggested for use is provided to the readers for suggestion only. Please hire licensed consultants to help you whenever you write contracts, you will find their assistance to be invaluable.

Susan Davey is the Business and Construction Warranty manager at Texas State University in San Marcos, Texas. She has written and managed large contracts for elevator and fire systems inspection and maintenance. She is a member of the Texas division of ASME, serving on the scholarship committee. Davey is a licensed nursing home administrator in Texas and has written the first emergency evacuation plan for a nursing home in Texas, which is to be approved by the governor’s office. She is currently pursuing her Master of Arts in Technical Communication at Texas State University. Her passion for the elevator industry was sparked by her interest in increasing accessibility and safety for the elderly and for those with special needs.

Get more of Elevator World. Sign up for our free e-newsletter.