Terminal 4 of the Sky Harbor International Airport, Phoenix, Arizona

Jan 1, 2012

Category 4: Escalators, Modernization

ThyssenKrupp Elevator’s Phoenix branch was awarded the contract for the escalator installation and modernization at the Sky Harbor International Airport in Phoenix. Due to the large size of the project, it was broken into separate jobs and contracts, and required multiple general contractors. The portion of the project to be highlighted is the escalator replacement at Terminal 4, which was completed in November 2010. The overall complexity of the installation made the project challenging and exciting.

The airport is one of the nation’s 10 busiest, servicing more than one million passengers per month. With such high traffic, Thyssenkrupp Elevator was held to strict safety requirements and limited construction space, and travelers had to have continuous access to at least one running escalator at all times. Despite the obstacles, the project met all American Public Transit Association guidelines, while providing an energy-efficient design.

Another challenge ThyssenKrupp Elevator faced was the inability to install commercial escalators, as they would not withstand the traffic demands. Instead, the company installed its Victoria transit-duty escalators. To meet the city’s energy-efficiency request, the escalators were equipped with LED lighting and proximity-sensitive radar sensors. The sensors reduce speed based on escalator usage using a “sleep mode.” When there are no passengers for three full revolutions, the equipment slows to a speed of 25 fpm, ultimately conserving power. When a passenger approaches the escalators, the sensor is activated and alerts the controller to increase the speed back to the normal travel speed of 100 fpm.

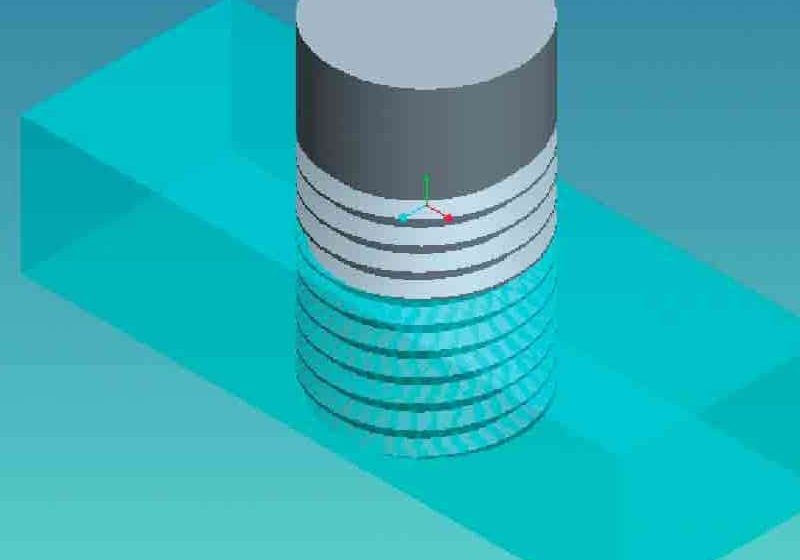

Two existing commercial-duty escalators needed to be demolished and removed. Three additional transit-duty escalators and trusses were specified to be installed in the existing footprint. Allred Metal Products was entrusted with the construction and design of the gantry system required to fit into a limited staging area, while supporting the weight of the escalators. The gantry system was critical to the installation because of several job specific variables. The sizes of the escalator pieces were so massive that a staging area on the west side of the airport was designed to store the materials until assembly.

Installation and assembly was further complicated by the airport’s stipulation that construction had to be performed between the hours of 10:00 p.m. and 5:00 a.m. The working hours were established for two reasons: public safety and to minimize disruption of the airport’s business operation during peak times.

All nine sections of the equipment were individually lifted by crane onto a flatbed trailer, then unloaded as the sections were needed for installation. The demolition and removal of one of the existing units was required, before installation could begin. Also, an opening had to be created that would accommodate the larger pieces. This required a contractor to remove the entire wall that led to the exterior of the building to allow enough room for ThyssenKrupp Elevator to roll, hoist and lower the new units into place.

The installation was a carefully orchestrated process that required each section to be lifted using air hoists. While hoisted, using six pick points, the three main sections were bolted together or assembled, and carefully lowered into place. The gantry system secured the escalators in place during active construction, while complying with the highest OSHA safety standards for public protection.

Specifications

- Rise: 38 ft., 3 in.

- Incline: 30º, spanning three floors

- Drives: Variable voltage, variable frequency

- Speed: Up to 100 fpm

- Travel direction: Reversible

- Converter: Radar-sensitive frequency

- Cladding: Stainless steel

- Balustrades: Glass

- Controls: PLC, non-proprietary

- Lighting: LED under-handrail lighting

- Emergency-stop button: Vandal resistant, located at each landing

Credits

- Owner: City of Phoenix

- General contractor: Hensel Phelps Construction

- Elevator consultant: Vertical Transportation Excellence (VTX)

Consulting - Gantry design: Allred Metal Products

- Gantry engineer: Gervasio &

Associates - Structural engineer: Nabar Stanley Brown, Inc.

- Architect: Gannett Flemming

- Manufacturer and components: ThyssenKrupp Norte

- Installer: ThyssenKrupp Elevator

Get more of Elevator World. Sign up for our free e-newsletter.