Test Tower Talk

Jan 1, 2020

Your author (OQ) chats with Professor Ignacio Herrera (IH) about Spanish university’s contribution to the vertical-transportation industry.

The elevator test tower at the University of Badajoz has contributed a touch of distinction and modernity to the skyline of Badajoz, Spain. The top of the 40-m-tall tower is accessible by corridors along its perimeter spaced upward every 3 m, and the tower can accommodate up to eight elevators for testing. The tower was designed with technological advances, such as advanced functional electro-stimulation (FES) equipment that allows for kinematic, dynamic and complete analysis of a biomechanical model of the human body inside the test elevator so that the lift can be evaluated for use in public buildings. The tower has been promoted by the INGELEV Research Group at the University of Extremadura, a collaborative facility where other research organizations, such as the School of Industrial Engineering — specifically, the Dédalo group of Mechanical Engineering — and the PE&ES group of Power Electronics can work together. Your author (OQ) sat down with Professor Ignacio Herrera Navarro (IH), sponsor and scientist responsible for this project, to learn more about the project.

Professor Herrera earned a PhD in Industrial Engineering from the Polytechnic University of Madrid in 1982, where he has served as Professor of Elasticity and Strength of Materials since completing his studies. In 1986, he was appointed technical director of the elevator laboratory at the university, undertaking its creation and commissioning by the then-Ministry of Industry and Energy as a facility accredited for homologation of elevator safety components within the framework of the European Commission Lifts Directive. In 1996, he was appointed Professor of the Area of Mechanics of Continuous Media and Structural Theory at the School of Industrial Engineering at the University of Extremadura. He is the author of numerous articles in scientific journals, especially in the field of elevator engineering.

The construction project for the elevator test tower at the University of Extremadura, a project for which Herrera has served as promoter and scientific manager, was completed in 2013.

OQ: How did the idea of creating this test tower come about?

IH: In 1997, after joining the University of Extremadura as a professor and seeing the availability of space on the university campus, I had the idea to continue the research I had been doing in the Laboratory of Elevators of the Polytechnic University of Madrid beginning in 1986. Aware that quality research in elevators of medium and high speeds required the verification, by experimentation, of the theoretical situation, the first project for which we sought funding was construction of an elevator test tower.

OQ: Explain the characteristics and functionality of this tower in the current context.

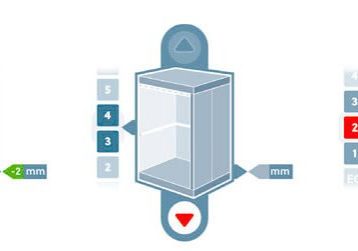

IH: It consists of two 40-m-high, 8-x-3-m2 shafts, accessible along the perimeter through aisles every 3 m. The assembly and dismantling of elevators are facilitated by a 4-mT crane bridge and two baskets for operators that can circulate through the shafts.

The tower has a machine for freefall tests up to 40 m high; impact tests for masses of up to 10 mT; and energy-dissipation tests up to 100 kJ, specially designed for the testing of progressive safety gears, dampers and elevator safety gear valves. It also has an attached laboratory for static, dynamic and fatigue testing purposes of electromechanical elevator components.

The tower has been promoted by the INGELEV Research group of the University of Extremadura. Given the multidisciplinary nature of elevator technology, the tower is also helpful for other School of Industrial Engineering research groups, especially the Dédalo group of mechanical engineering and the PE&ES group of power electronics.

OQ: Can you detail the type of technological tests in the field of elevation that you want to experience in the test tower?

IH: The tower is specially designed to reduce assembly times and the proper disassembly of a proposed R&D full prototype elevator (or parts of it) for medium and high speed. At present, up to eight complete lifts can be tested simultaneously.

OQ: What is the capacity of the test tower?

IH: With the help of equipment the ministry has just granted us, apart from very substantially improving the operation of the installation both inside and outside the tower, we will have the following equipment:

A modular test elevator for testing, with passengers, elevator components at speeds up to 2.5 m/s, which allows aptitude testing of the function of elevator components; setup and training on expert systems of predictive maintenance and elevator traffic; and for tests of elevator-passenger mechanical interaction regarding studies of comfort and safety for passengers, including disabled people and hospital patients.

A modular test elevator for testing, without passengers, of elevator components at speeds up to 7 m/s, which is designed especially for testing advanced elevator control systems and mixed solutions for energy efficiency, especially through integrated photovoltaic panels on the façade of buildings, which, in addition to generating energy, offer thermal and acoustic insulation. It is also used to test braking and regenerative-control equipment that have autonomous energy storage systems through semiconductors without the need to re-inject energy into the network, and has the capability of detecting and filtering voltage oscillations and annoying operating noises.

There is also a mini-lift for guidance/suspensions/full-lift operation/elevator battery testing at 1/10 and 1/20 scale, up to 20 m/s. It can be used for control and roll-suppression (sway) tests, and building-elevator interaction: seismic, cyclonic wind over buildings and aerodynamics of the elevator (tunnel effect).

OQ: The tower project includes advanced functional electrostimulation (FES) equipment. Could you provide more details in this regard, in relation to the purpose and functionality of such equipment for its implementation in public places?

IH: In fact, the FES equipment, together with a reaction-force measurement plate of the human body against the ground, synchronization equipment between force measurement plates and infrared motion-capture cameras will allow us to perform a kinematic, dynamic and complete analysis of a biomechanical model of the human body inside the elevator. The objective of this equipment is twofold. On the one hand, it can be optimized for operation while accelerating, riding and braking the lift, in terms of comfort for the user: forces transmitted to the joints, vibration transmitted to the human body, etc. That is, a first objective is to include the biomechanics of the subject(s) in the elevator design. The other objective is to convert the test elevator into a biomechanical test platform under conditions of high acceleration, reduced gravity, impacts, etc. using the dynamic conditions of the elevator to study situations of purely biomechanical interest; for example, adaptation and control strategies for motor, balance, etc. and for the design of biomedical engineering devices, such as exo-hybrid skeletons that “absorb” impact situations during tests under controlled conditions in which the elevator is subjected to abrupt deceleration by ramps or by safety-gear activation.

OQ: What is the approximate date the tower will be completed and 100% operational?

IH: December 2021.

OQ: What does this tower represent for the University of Badajoz and for its industrial engineering students?

IH: The elevator test tower has altered the skyline of the city of Badajoz and the university campus. It is an example to follow when bringing the world of business and industry to the university, which has seemed more concerned with growing the number of degrees offered than with providing excellence and specialization in the degrees offered. For master’s and doctoral students in industrial engineering, the tower represents the opportunity to receive experimental training that is specialized in elevator engineering.

OQ: Have you entered into any kind of collaboration with international teams with an aim toward overcoming some challenge in the field of elevators?

HI: INGELEV has contributed to the study of the comfort of passengers through analysis, simulation and mechanical testing of the lift system, taking into account the damping capacity of passengers and goods. This group has been collaborating with several research teams, both in the business and in the university field internationally. There has also been close collaboration with the Lift Engineering division of the University of Northampton (U.K.) in investigations into the interaction of elevators with passengers and into the suspension means of elevators used in high-rise buildings, especially for the control and suppression of roll (sway).

OQ: From your point of view, what are the biggest challenges facing the elevator field?

IH: The biggest challenge in the strict sense is, undoubtedly, the space elevator. The National Aeronautics and Space Administration has funded research on this revolutionary idea that would allow goods and people to be transported to an orbiting station, or satellites to be placed into orbit, but has not yet funded any project for its construction.

However, the biggest challenge in the field of lifting is to improve elevators so that they operate safely and comfortably, can sustain longer journeys, and can carry more people and loads per unit of time. This challenge becomes more relevant with the growing interest in the construction of high-rise buildings. Beyond that, we have the challenge of several unresolved technological limitations. These include the underdevelopment of high-speed lifting technology; improvement of critical components, such as a lighter, stronger replacement for steel rope (carbon nanotubes have shown significant improvement in this area); and improvements in comfort and sustainability, which would go hand-in-hand with elevator cars in which friction did not influence their guidance (contactless guidance: the guides did not require lubrication [dry guidance]).

OQ: How many towers exist in the world with characteristics similar to this one’s? What news will this tower located at the University of Badajoz bring to the existing ones?

IH: The elevator multinationals do have elevated towers (some reach heights greater than 200 m) or excavated wells (more than 300 m deep) for testing their own elevator prototypes. Although their travel distance is very high, none of these can meet the needs of the tallest buildings already constructed (such as the 828-m Burj Khalifa), so in these cases, you must use the building under construction as its own testing tower, with the inherent limitations this brings.

The Badajoz Elevator Test Tower is available for any research/development/innovation project, both public and private purposes, for a complete elevator or elevator component, through the signing of agreements that guarantee independence and confidentiality of research results.

The tower, through its innovative conception as far as accessibility to the elevator system and adaptability to the needs of investigation, allows a substantial reduction of the times of assembly and disassembly of complete elevators and their components. Moreover, taking into account the number of simultaneous test elevators, shaft and height measures, as far as we know, there is no other built tower of similar or better performance. Thanks to the new equipment to be installed in it, we will bring a test capacity for lifts characterized by a substantial reduction in the design, development and installation times for new lift prototypes and components.

More information on the test tower and the Elevation Engineering Center of the University of Extremadura can be found at

https://www.eweb.unex.es/eweb/cie/?

Olga Quintanilla is a freelance journalist, community manager and blogger known for her writing for mass media related to health issues, tourism publications, culture, technology and social media responsibility. For 20 years, she was parliamentary correspondent for the Balearic Hora Nova Media Group. She currently serves as media manager for the Spanish Association of Professional Technician Firefighters (APTB).

Get more of Elevator World. Sign up for our free e-newsletter.