The 1876 Centennial Exhibition, Part I

Nov 1, 2013

International exhibitions and trade shows are common aspects of the 21st-century commercial landscape, and the frequency with which these events occur easily allows companies – and countries – to maintain a global perspective and awareness of industry trends. The presence and importance of national interests in the development of new technology has been a critical aspect of industrial exhibitions since the first such event was held (the 1851 Crystal Palace Exhibition in London). In the 19th century, the expression of these interests is found in the official reports produced by visiting national delegations. These reports were intended as a means of industrial and cultural education and are important because their subject matter was observed, understood and interpreted from a different national perspective than that of the host country. The report published by the Austrian Commission to the U.S. Centennial Exhibition of 1876 illustrates this process of investigation and interpretation. The Centennial Exhibition, held in Philadelphia, featured the largest collection of American elevator machinery assembled in one location and included exhibits by 19 companies from across the country, as well as exhibits by Canadian and French firms.

The Austrian delegation report, titled Passenger Elevators, Freight Elevators and Mine Hoists was written by Alois Riedler (1850-1936). Riedler was a mechanical engineer and, at the time the report was written, he was on the faculty of the Technical University of Vienna. His detailed report consisted of 81 pages of text, nine line drawings embedded in the text and 13 plates of illustrations that contained 97 individual line drawings. Riedler’s report represents, in essence, the first attempt to write a comprehensive summary of vertical transportation in the U.S. His efforts to be as comprehensive as possible were evidenced by the fact that, in addition to thoroughly examining the machines exhibited in Philadelphia, he also researched and collected drawings of elevators not featured in the exhibition. The latter group included hydraulic elevators designed by Lane & Bodley Co. (Cincinnati), William B. Le Van (Philadelphia) and William E. Hale (New York); and blast-furnace hoists designed by P.L. Weimer & Brothers (Lebanon, Pennsylvania) and Taws & Hartman Machinists and Brass Founders (Philadelphia). Riedler also provided detailed descriptions of mine hoists in Nevada and Colorado and of the elevator designed by Mégy, Echeverria & Bazan (Paris).

The report opened with a general introduction and discussion of what Riedler characterized as the widespread use of elevators in American cities. He claimed that elevators in industrial settings and warehouses were viewed as a necessity due to their use as “labor saving” devices, which were critical aspects of efficient and economical business operations. He also claimed that the presence of elevators in hotels, retail stores and public buildings was so pervasive that stairs were now perceived as a “secondary” means of vertical movement in buildings. He stated that the extensive use of elevators resulted from an American desire for personal comfort and efficient business operations, and the availability of a cheap and dependable power source – steam.

Riedler claimed that “more than 90% of American elevators are operated by steam engines.” The widespread availability of steam power was seen as uniquely American and as contributing to the ease with which elevators could be installed and economically operated. According to Riedler this was possible because “no law in America prohibits the installation of steam boilers, even in the centers of large cities.” He also cited the availability of an ample supply of anthracite coal, which he described as burning “completely smokeless,” as promoting the use of steam power. He reported that these circumstances were “distinctly American” and implied that they would have been “impossible” to replicate in Austria. In other words, differing national resources and building laws had a direct impact on the application and availability of elevator technology. The introduction concluded with a general overview of technical details and elevator operation. Perhaps the most interesting aspect of this summary is the references to the apparently common use of electric signal systems to call elevators to a given floor.

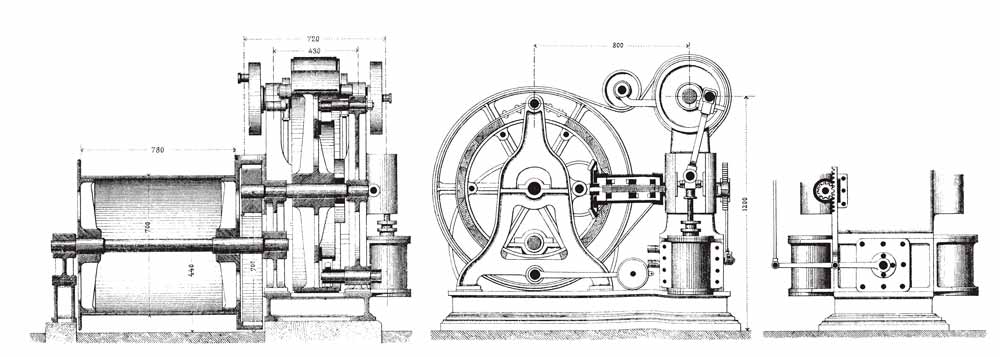

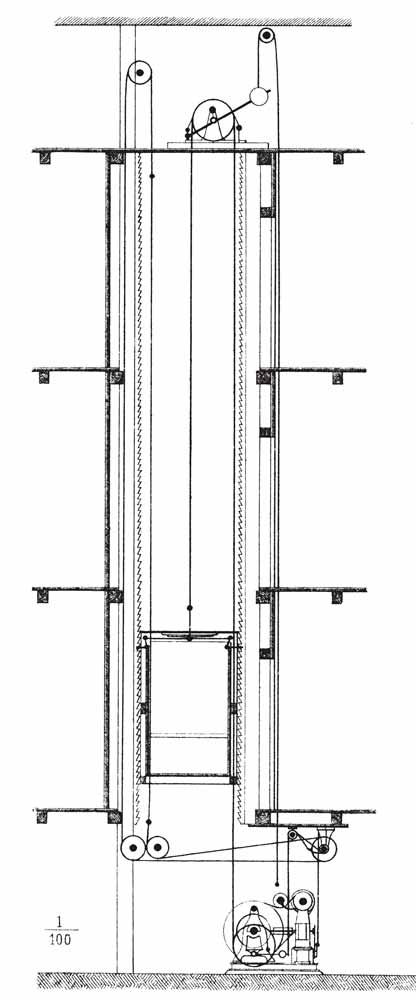

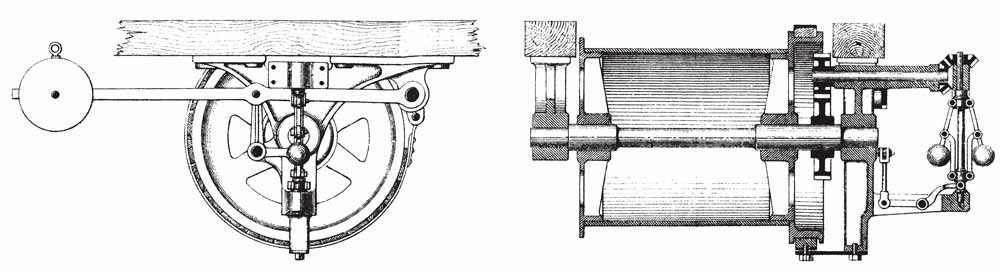

Riedler began his detailed account of elevator systems with a discussion of the machines displayed by Otis Brothers, who offered visitors a large exhibit that consisted of a “complete collection” of their steam-powered elevators. The machines described in the report included the “New York” safety passenger elevator, the “Metropolitan” elevator and the “Universal” elevator. The “New York” was designed solely for passenger use and equipped with Otis Brothers’ reversible double-cylinder steam engine (located in the cellar or basement), safety drum (located at the top of the shaft) and numerous patented safety devices, including a version of Elisha Graves Otis’ 1861 ratchet safety (Figures 1 and 2). One of the most interesting drawings published in the report was a section that depicted a complete elevator installation (Figure 3). This drawing is one of the few published images that provided a clear understanding of how these machines were typically placed in a building (from basement to attic). Riedler provided a comprehensive report of the entire system, which included such details as the fact that the shape of the counterweights depended on their location: “in most cases,” the counterweights were composed of flat cast-iron plates; however, when they were required to run inside enclosed chases, they employed a cylindrical profile.

The report included a table of technical data and prices, which appears to have been (in part) a translation of information found in a typical Otis Brothers sales brochure (Table 1). The table described the volume of space occupied by the steam engine (length, width and height), typical shaft dimensions (ranging 1.52-2.26 m2 in size), the prices of the various models shipped from Otis Brothers’ factory in Yonkers, New York, and the prices of these same elevators installed by Otis in or near New York City (NYC). The price for the installed system included the steam engine, safety drum, counterweights, ropes, car and all wages associated with the complete assembly “up to the starting of the elevator.” While, perhaps logically, the price excluded the cost of the steam boiler and associated piping, it is of interest that the price also excluded all elevator shaft work (guide rails, doors, etc.). The two sets of prices (shipped versus installed) allow a rough calculation of typical installation costs, which equaled approximately 13.5% of the total cost of an installed system. The prices were also predicated on a total run that did not exceed 25 m. For longer installations, Otis added an additional cost that varied depending on the model number. (This figure was not supplied for the “New York” elevator; for the “Metropolitan” elevator, this cost varied from US$3 to US$6 per foot). Riedler also reported that systems that utilized a “simple car design” would have a US$250-500 price reduction. The “New York” elevator’s typical operating speed was 30-60 mpm.

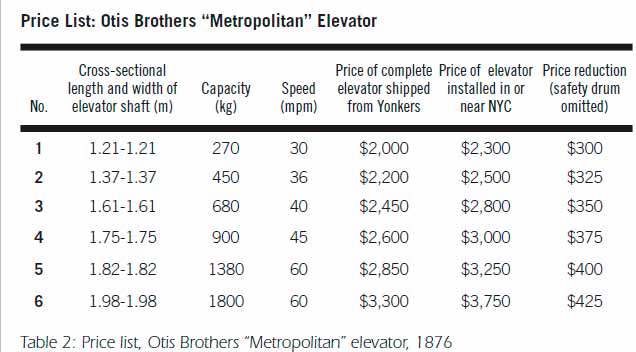

The description of Otis’ “Metropolitan” elevator was less comprehensive than that provided for the “New York”: because it included the same safeties, steam-engine type, etc. used in the previous system, Riedler doubtless felt it was unnecessary to repeat this information. Riedler also chose not to include illustrations of this system in his report. Although the “Metropolitan” was described as having been designed for either passenger or freight use, its base price included an open platform instead of an enclosed car, a clear indication that its primary use was intended as a freight elevator. A table of technical data and prices for this elevator was also provided (Table 2). Apparently, it could be purchased without the safety drum, and the corresponding price reductions were included in the table. This is somewhat surprising given Otis’ reputation for safety. Riedler also implied that these machines typically shipped with only one hoisting rope. If a second rope was desired, there was an additional cost of US$400-600. The base price of the “Metropolitan” was predicated on a total run height that did not exceed 30 m.

“Riedler’s report represents, in essence, the first attempt to write a comprehensive summary of vertical transportation in the U.S.”

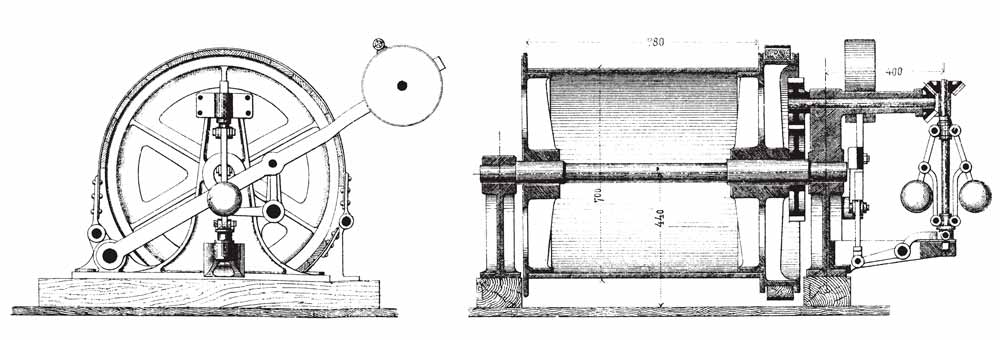

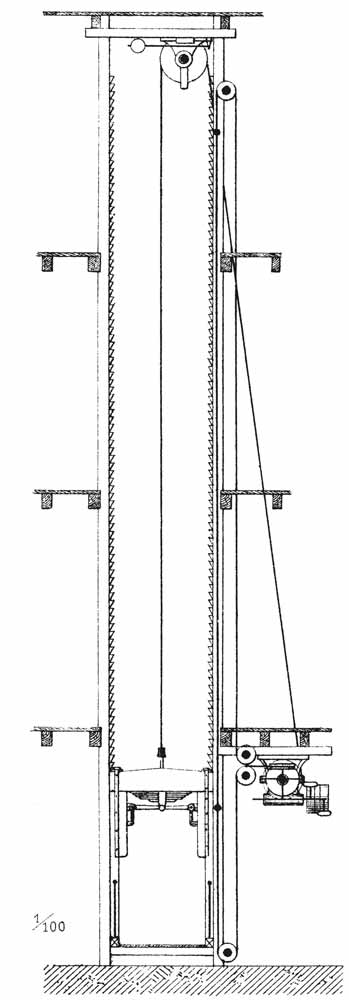

Riedler’s description of the “Universal” elevator included the same high level of detail and number of illustrations that accompanied his examination of the “New York” elevator. This was because this system was designed solely as a freight elevator and was a belt- rather than steam-powered machine. The use of two leather belts to power the elevator “engine” meant that it followed the paradigm of factory machinery involving a system of continuously rotating leather belts attached to pulleys on line shafting that extended throughout the building. The illustrations included a section that depicted the complete elevator installation (which provided a clear understanding of how these machines were typically placed in a building), as well as detailed drawings of the belt-powered engine and safety-drum system (Figures 4-6). Riedler once again provided a detailed table of prices and technical data on the elevator’s various configurations (Table 3). The information found in this table included standard platform sizes, costs for platforms accessible on either four or two sides, and packing charges. Larger platforms could be ordered with an additional US$32-43-per-m2 cost. The fact that no installation costs were provided indicates these machines were typically installed by local mechanics at the factory site.

Part two of this article will continue this examination of the American elevator industry in 1876 as seen through the lens of Riedler’s report for the Austrian delegation. Its focus will be on hydraulic elevators.

Figure 5: Otis Brothers “Universal” elevator, safety drum, 1876

Figure 1: Otis Brothers “New York” elevator, steam engine, 1876

Figure 2: Otis Brothers “New York” elevator, safety drum, 1876

Figure 3: Otis Brothers “New York” elevator, installation section drawing, 1876

Figure 4: Otis Brothers “Universal” elevator, engine, 1876

Figure 6: Otis Brothers “Universal” elevator, installation section drawing, 1876

Table 1: Price list, Otis Brothers “New York” elevator, 1876

Table 2: Price list, Otis Brothers ”Metropolitan” elevator, 1876

Get more of Elevator World. Sign up for our free e-newsletter.