This solar-/water-powered elevator is a step toward reducing the use of electric power.

by Ish Buckingham

The lift industry is currently devoting a great deal of time and, dare I say, energy into developing “green” products that will contribute to the global objective of preserving our planet for future generations. The general trend is to find ways of reducing rather than eliminating the use of electrical power.

I was therefore intrigued, to say the least, when I heard about a solar-/water-powered lift, which had been installed for a two-week period in London as part of the London Festival of Architecture 2010 – the U.K.’s largest celebration of architecture, which took place between June 19 and July 4.

Matthew Lloyd of Matthew Lloyd Architects created the working prototype in collaboration with the Royal Engineers, Architecture Inside Out and the Royal Institute of British Architects. The concept, which had the support of The Royal Parks, was designed to raise public awareness around access and sustainability, firmly placing the key issues of inclusive design and equal access under the spotlight. Disability arts groups Shape and Architecture Inside Out were consulted to ensure that the design was relevant and worthwhile.

Hailed by Matthew Lloyd as the world’s first water- and solar-powered lift, it was installed at the foot of the Duke of York column on the historic Duke of York Steps adjacent to the Institute of Contemporary Arts at the eastern end of the Mall in St. James’ Park.

Matthew Lloyd said of the project:

“Although the world of lift design and engineering has often investigated water-powered lifts, we believe that

no one has ever before created a gravitational water-powered passenger lift in a normal architectural format.

“In addition to achieving carbon neutrality, the use of water and solar power means the design can be used in the developing world where access to mains electricity may be intermittent or nonexistent, as well as on urban sites, either permanently or as a temporary installation (e.g., for events such as the Olympic Games). The lift is constructed of steel, Perspex®, and aluminum and is entirely recyclable.”

The original intention was to build a series of three lifts to provide access from the top set of steps to the bottom; but, as this was impossible for the exhibition due to time and budget constraints, a single lift took users from the top to the middle section of the steps and back again.

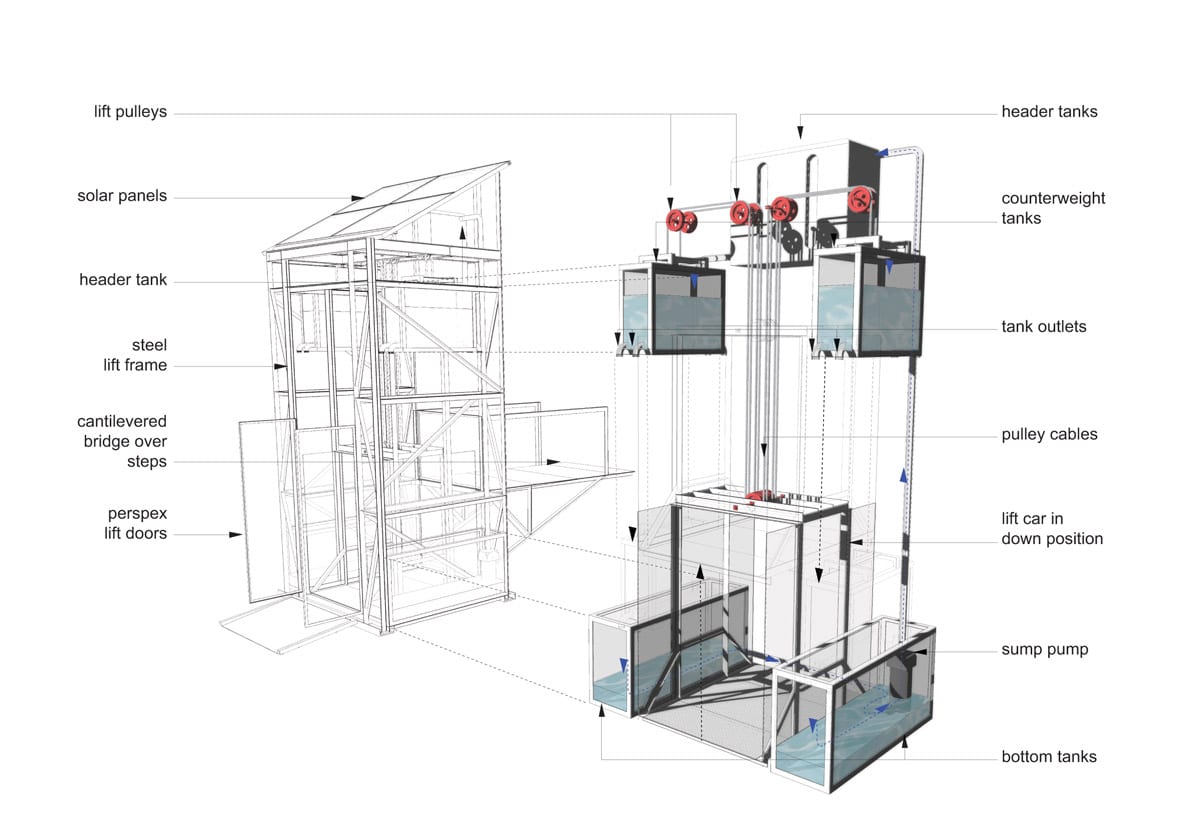

The lift was installed within a steel tower, clad externally with Perspex sheeting so that the operating mechanisms and concepts could be fully appreciated by the general public. The Royal Engineers were consulted as experts in site-specific solutions, as well as for their historic connections to this part of central London.

The Royal Parks, which kindly granted permission for the installation, were naturally insistent that there be no mechanical fixings to the old stonework. This is an essential consideration for sites of historic significance. The solution was to avoid bolting the lift down, so that

it sat freestanding on the steps with a bridge that cantilevered out from the main structure.

The installation had two counterweight tanks, one on either side of the lift car. The counterweight tanks produced the necessary force to enable the lift car to rise and lower via a 2:1 roping system. A header tank was located at the top of the lift shaft, and two fixed storage tanks were located at the bottom of the lift shaft, one below each counterweight tank.

Assuming that the lift car was positioned at the lower level with the counterweight tanks positioned at the high level, the release of valves in the bottom of the header tank allowed water to fall into each counterweight tank, thus increasing the weight of each counterweight tank and powering the lift car into the up position and counterweight tanks into the lower position.

The release of a second valve at the bottom of each of the counterweight tanks allowed water to fall into each of the two fixed storage tanks, thus decreasing the weight in each counterweight tank and allowing the lift car to descend under gravity. A solar-powered 800W pump pushed water back to the header tank, ready for the next cycle.

The solar power was generated by a photovoltaic system, which enabled the sun’s radiation energy to be transformed into electrical energy. This phenomenon was accomplished by means of solar cells. As a rule, solar cells consist of the semiconductor silicon, which is particularly suitable for the manufacture of solar cells because of its high availability, low raw-material costs and simple transformation. Semiconductors are substances that become electrically conductive when they are exposed to light or heat. Solar cells are essentially structured into two layers, one of which is negatively charged, with the other positively charged. As soon as sunlight strikes the layers, a voltage tension develops between them. This generates direct current within the solar cell. In order to be able to use this current, photovoltaic systems have a power inverter or AC converter.

Tony Heaton, chief executive of Shape, said:

“The lift is different because it is fun: it does not look like a medicalized piece of kit for disabled people, unlike most wheelchair lifts.

“Usually, it seems as though designers associate disability with illness out of ignorance, and this comes across in their designs. As it is a prototype, improvements could obviously be made; but this is an interesting solution to an access problem and, crucially, it draws attention to the lift rather than to the person. Clearly, the lift needs to be fully functioning to fulfill its purpose, but this demostrates that it can be so with style and elegance.

“The way that the public has engaged with this lift suggests that [it is] not use to seeing anything like this, and it provokes fascination, drawing spectators like bees around a honey pot. Creating a lift [that] doubles as a piece of theater is of benefit to disabled people, who very often are unintended performers; this shifts the focus from the person to the machine.

“Placing the lift slap bang in the middle of the steps was deliberate: not only did it please Matthew Lloyd’s architectural logic in maintaining the symmetry and allowing the usual flow of pedestrians at either side of the steps, but it also gives access a central focus, putting disabled people at the center. Too often, disabled people are forced to slink in the back way, but this presents a solution [that] is impossible to ignore.”

Matthew Lloyd commented:

“For me, a key point about this project is that it was a genuine collaboration between architects and disabled people. Rather than an architectural polemic, it is a highly functional machine, which was built to solve a physical problem on a major site. The location is unparalleled in its historic status: with Grade I listing, it has the highest level of historical protection, and Royal Parks, which kindly granted permission for the installation, were naturally insistent that this be respected. Our solution was to avoid bolting the lift down, so that it sat freestanding on the steps, with a bridge that cantilevered out from the main structure. The small 800W water pump was powered by solar energy, and as the lift was constructed from steel, Perspex and aluminum, it was entirely recyclable. Furthermore, the whole structure could be dismantled and removed by crane in half a day.”

Lloyd describes this design as “genuine sustainability – as distinct from cosmetic sustainability.” Using renewable energy not only addresses the need to unlink our lives from fossil fuel, but also allows the lift to be used away from mains electricity. And incredibly, thanks to the goodwill and enthusiasm of some lift specialists and renewable energy providers, it cost just GBP10,000 (US$16,000) to produce.

The prototype lift for the London Festival of Architecture was constructed thanks to the following companies:

- Steel frame by: T Good & Sons (www.tgssteels.com)

- Solar panels: Sanyo (www.sanyo.com)

- Pump: Whale Pumps (www.whalepumps.com)

- Aluminum: Gooding Aluminum (www.goodingalum .com)

- Skates and pulleys: Pfaff-Silberblau (www.pfaff-silber blau2.co.uk)

- Perspex: Perspex Distribution (www.perspex.co.uk)

- Acrylic fabrication: Hamar Acrylic (www.hamaracrylic .co.uk)

- Bespoke hydraulic pistons: Interfluid Hydraulics Ltd. (www.interfluid.co.uk)

- Hydraulic hoses: Pirtek UK Ltd (www.pirtek.co.uk)

- Off-grid battery charger and inverter: SMA Solar Technology AG (www.sma.de)

- Hydraulic dampers: Ace Controls (www.acecontrols .co.uk)

Get more of Elevator World. Sign up for our free e-newsletter.