The Gen360™ Platform, the Next Generation of Digital and Sustainable Elevators

Feb 1, 2024

by Pascal Rebillard, Alper Caliskan and Vijay Lakamraju

This paper was presented at the 2023 International Elevator & Escalator Symposium in Edinburgh, Scotland.

Abstract

The megatrends of urbanization and our changing interactions with building spaces continue to bring new opportunities and challenges in vertical building transportation. Continuing its legacy of innovation, Otis meets these demands with the Gen360TM platform by incorporating a myriad of digital and energy-efficient technologies offering new safety and security features, improved customer service and experience and reduced environmental impacts.

The Gen360TM platform is a true digital revolution. It includes Programmable Electronic Systems in Safety Related Applications for Lifts (PESSRAL), a new electronic hardware-software system that achieves the latest international safety standards and provides enhanced diagnostics. Greater safety for service technicians was made possible by allowing mechanics to access the car top from a platform inside the car. Dedicated Internet of Things (IoT) solutions collect important data and create insights regarding elevators’ health using big data analytics. These insights are used for predictive maintenance and for drastically reducing downtime. Greater remote interactivity reduces the need for in-person maintenance activity, increasing the unit’s availability and also reducing CO2 emissions from vehicular traffic from mechanics’ site visits. In-car displays provide better interface and communication for passengers. However, increased digitalization and connectivity raise exposure to cyber-attack. With the Gen360TM platform, Otis has taken bolder steps in implementing key cybersecurity controls, including secure boot, multi-layer secure communication and a cloud-based backend with required authentication and authorization procedures.

Design optimizations such as advanced deep standby power mode have been employed to have a positive impact throughout the product’s entire life cycle, resulting in environmental benefits. The Gen360TM platform has achieved A-class energy efficiency according to the ISO 24745 standard, creating both energy savings and credits for buildings and municipalities.

The combination of native digital connectivity with smart use of sustainability features makes the Gen360TM platform the new market standard for vertical mobility system platforms.

1. Introduction

Among the megatrends for the future, urbanization is one of the most significant. As explained in a United Nations report,[1] 55% of the world’s population lives in urban areas and by mid-century, approximately two-thirds of the world population (68%) will be living in cities. Overall, by 2050, the global urban population is expected to increase by 2.5 billion dwellers. It is also said that during that period of time, with 5.6 billion urban dwellers, the less-developed regions are projected to have 83% of the world’s urban population and 87% of the total world population. Moreover, by 2030, according to some projections, the world will have 43 megacities with more than 10 million inhabitants — many of them located in Asia and Africa.

Another report from the United Nations[2] shows that the continuous growth of urbanization is also accompanied by another major global phenomenon: the aging population growing faster, and now including Africa and parts of Asia.

This demographic evolution leads public authorities to legislate to ensure the elderly (sometimes with some disabilities) can benefit from the advantages of urbanization by setting rules regarding access to public infrastructure, as well as the use of different types of mobility equipment for resilient housing and buildings.[1]

It’s a fact that urban growth drastically increases pollution and consumption of raw materials and energy.[3] Currently, urbanization generates most of the total greenhouse gas (GHG) emissions and accounts for more than 75% of the total consumption of resources (including energy) and 50% of global waste.[2] Moreover, 30 years from now, cities will use roughly 80% of the entire planet’s natural resources.[2] So, it makes sense that international organizations, non-governmental entities and civil societies are calling for sustainable urbanization and for changes in public policies to transition toward low-carbon (which is a key factor in climate change), resource-efficient cities and overall, more effective implementation of conservation practices to prevent environmental degradation.[3]

Innovation plays an important role in sustainable urbanization. According to the McKinsey Global Institute,[4] digital solutions could improve some quality-of-life indicators by as much as 30%. In particular, digital technologies like IoT sensors, AI and cloud computing will enable early detection of failure issues and result in greater efficiencies. By doing so, these technologies will help address population growth trends, including the aging population, and provide a fighting chance against climate change by bringing the solution of efficient energy management systems, as well as renewable energy generation and storage.[2]

The world is at the nexus of megatrends ahead: population expansion, urbanization, digitalization and demand for more connected and sustainable cities. Change is constant. It also brings opportunities and challenges that require new solutions. Otis pioneered the lift business 170 years ago, and Otis’ business is strategically linked to the megatrends of urbanization and how people change in their ways of life and work.

2. What Makes the Gen360tm Platform Unique?

a) Understanding Customer Needs

Before designing the Gen360TM platform, all personas, from architects to owner/managers, were surveyed to find out how Otis could bridge the gaps with our offering. Five key areas to focus our innovation were uncovered:

Design-Space efficiency (unsightly roof protrusion) and sustainability

Safety-Risk of entrapment: Reduce undue stress to passengers caused by being trapped in a lift

Service-Unexpected interruptions: Need faster return to service.

Experience-Keeping up with passengers: Need technology that outmatches consumer expectations.

Support-Support the customer: Need tools to simplify the design, specs, installation and management of the unit

b) Design Reimagined

The design was conducted following an MBSE, or Model-Based Systems Engineering, approach, which consists of applying the three views: operational, functional and constructional.

The purpose of the operational view is to clearly identify the mission and the needs. The functional view identifies the functions necessary to meet the needs, as well as the flows exchanged between the different functions within the system, but also with the environment. Finally, the constructional view is where physical solutions are identified.

Another key driver concerning the development is that this new product has been built (mechanical, electrical, electronical, IoT) from the get-go as a global platform. True to the definition of a platform, it embodies a set of interfaces, parts, components, modules and sub-systems that form a common structure from which a stream of derivative products can be efficiently developed and produced.

The previous lift generation, Gen2®, was founded on a compact machine-room-less (MRL) design, thanks to using traction belts instead of ropes. Going beyond MRL design and introducing connectivity and IoT, the Gen360TM platform is a completely reimagined lift system made possible through holistic R&D that combines new equipment, software and service, and thoughtfully reimagines how to meet customer needs.

Space Efficiency-Maintenance From Inside the Car:

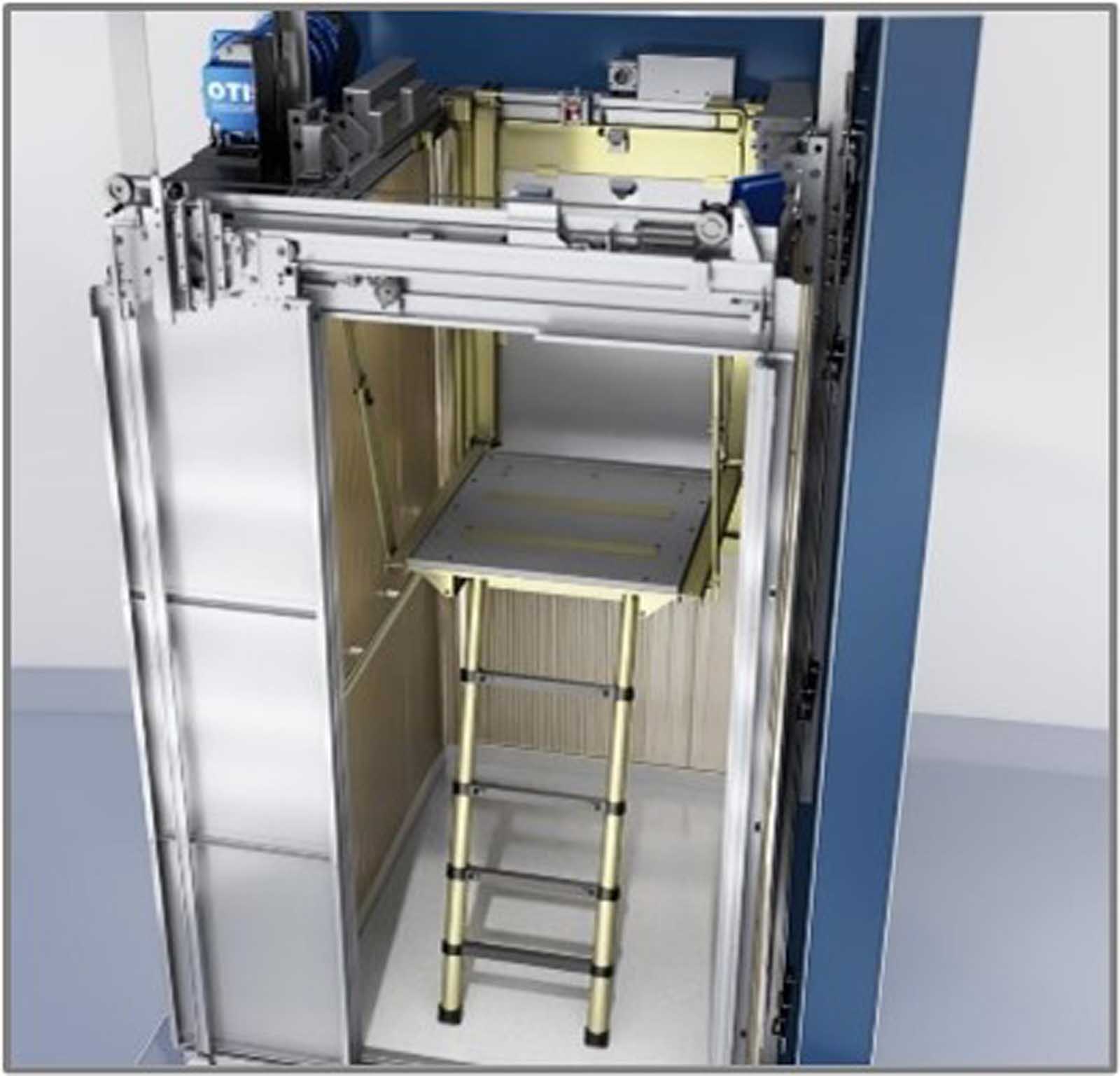

The Gen360TM platform maximizes car size and minimizes the lift footprint in a building. A refuge space between the top of the car and the top of the hoistway is required by EN 81-20 code to ensure presumption of conformity with the Lift Directive, protecting a mechanic performing maintenance operations from the top of the car. The mechanic accesses the car top from a working platform inside the elevator, allowing safe and ergonomic maintenance operations directly from inside the car (Figures 1 and 2).

The safety system prevents any unintended movement of the car when the platform is deployed. Construction is easier, faster, less expensive (construction and waterproofing of the protrusion) and also much more reliable with time, as the roof insulation doesn’t need to be cut.

The Gen360TM platform also includes some key features enabling an increase in hoistway efficiency:

- No more governor and tensioning pulleys, therefore freeing up space in the hoistway thanks to the Electronic Safety Actuator (ESA)

- A foldable toe guard; enabler for low pit for a robust and silent solution

- Low overhead and low pit combined

c) Safety Reimagined

The Gen360TM platform sets new standards for safety that make possible immediate situational evaluation and enhanced remote rescue thanks to new active safeties.

The key features and subsystem enabling that innovation are:

- PESSRAL architecture

- Absolute position reference system

- Electronic safety actuator, from mechanical to electronic safeties (electronic speed control and safety blocks triggering)

- Protection of manual door-unlocking mechanism that prevents any entrance into the hoistway

PESSRAL Architecture

The electrical architecture includes PESSRAL technology using failsafe electronics to monitor the safety chain. The Gen360TM PESSRAL architecture complies with the EN-IEC61508 functional safety requirements standard, making it possible to abandon the serial connection of all safety contacts in favor of a connection of the contacts to safety nodes. The benefits are:

- Foundation for service; condition-based maintenance

- Fast troubleshooting

- Integrated remote diagnostics

- Reduction in cost and wiring time

Absolute Position Reference System (APRS)

The car position reference system that equips the Gen360TM platform is made from devices that are APRS, EN-IEC61508 and SIL 3 certified. The APRS system basically consists of the APRS sensor and the APRS code tape. The APRS sensor uses optical scanning to determine velocity and position. Position and velocity information are transmitted over the interface to the downstream processing unit.

Electronic Safety Actuator (ESA)

Traditional lifts are equipped with mechanical overspeed governors in the hoistway. From a system integration standpoint, the use of traditional means of lift overspeed detection using centrifugal mechanisms is a penalty in regard to hoistway efficiency and installation time. The Gen360TM platform includes a significant Otis innovation: the ESA that replaces the mechanical overspeed governor.

The ESA allows monitoring of speed redundantly and automatically triggers the safety blocks. False overspeed entrapments generated by car bouncing are filtered out and, in case of genuine overspeed, the mechanical safety is triggered by the electronic safety actuation system. But, once the lift is stopped, Otis remote experts can remotely investigate. Additional functionality enables self-diagnostics, and communicating responses of fault conditions to PESSRAL that indicate loss of integrity of its interfaces and overall readiness to execute its primary functions.

Protection of manual door unlocking mechanism prevents any entrance into the hoistway.

The doors suitable to gain access to the top of the car are not equipped with the conventional triangular key, which is now replaced by the Single Use Unlocking Device (SUD). During normal use of the lift, i.e., normal use by passengers, handover tests or routine maintenance, there is no need to access the top of the car and consequently no need to provide access to the well through the landing door. The landing door is the physical barrier that prevents hazardous situations in the hoistway: falling and crushing. The SUD can be used exceptionally to help rescue in case of combination of multiple highly improbable events like the loss of all the rescue modes functions (e.g., failures of several components). The SUD allows one to open and lock the landing door thanks to the triangular key. However, when used, the lift can no longer operate in normally and the main functionality is permanently missed.

The Gen360TM platform and related safety sub-systems have been certified by Liftinstituut according to European Lift Directive 2014/33/EU and harmonized standards.

3. Digitalization of Lifts and the Gen360tm Platform Edge

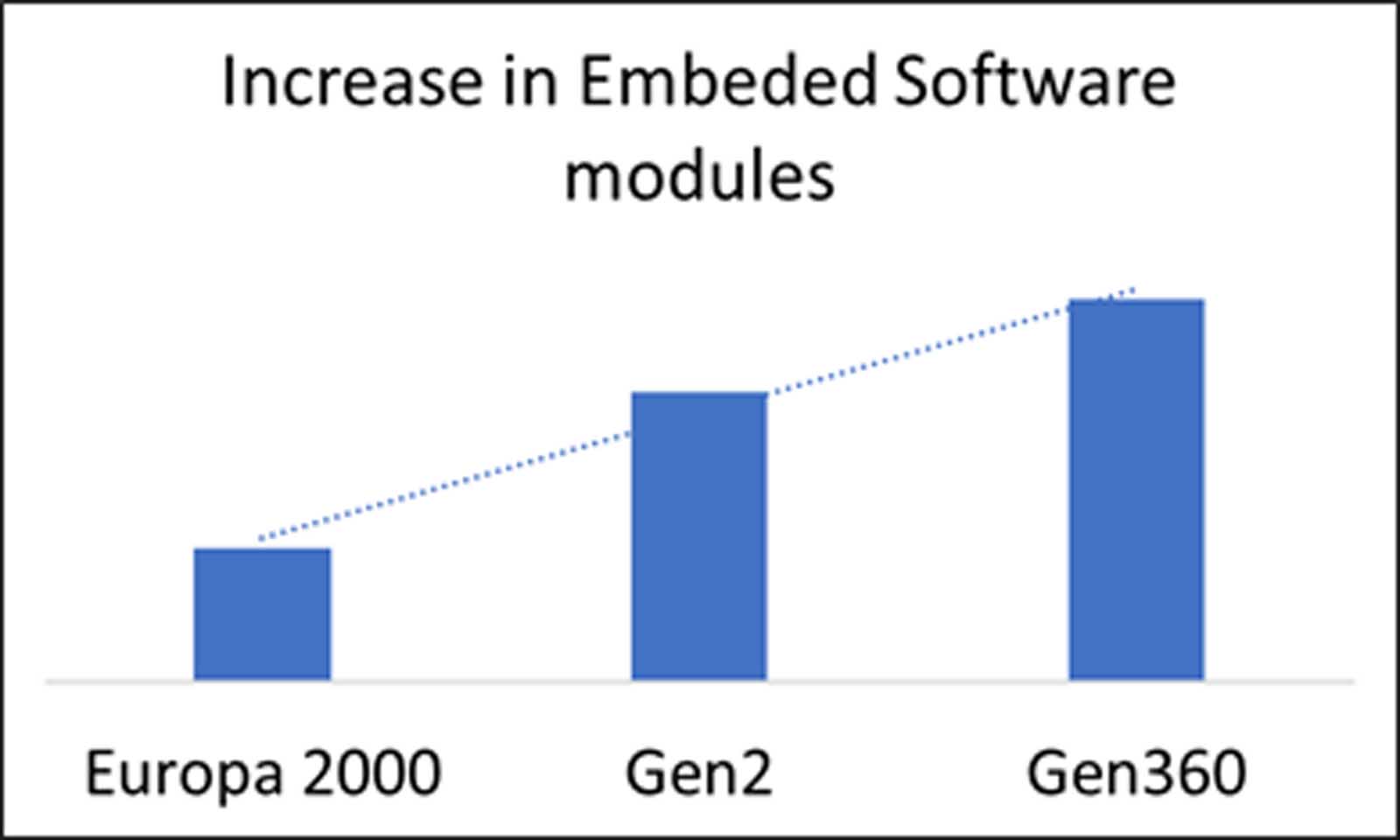

The lift industry, including Otis, has continuously adopted digital technologies over many decades. For example, Otis launched remote-monitoring systems using dial-up modems more than 20 years ago, but the speed of digitalization has increased dramatically over the past five-10 years. As computing, interfacing and communication technologies evolved, they have found their way into different parts of the lift system. This not only includes advancing IoT functionality, but also the use of technologies for seamless access using mobile phones, improving people flow through smart lift dispatching, enhancing the passenger experience (even in the case of unfortunate situations such as entrapment), integrating lifts into building management and using Application Programming Interfaces (APIs) to integrate service robots with lifts. Such types of digitalization have led to an increasing number of software modules, as well as sensors in the lift system.

The Gen360TM platform is a perfect example of a system embodying the digital revolution. Service teams are able to access real-time data on lift performance. This helps identify potential issues before they become major problems, reducing downtime and improving maintenance efficiency. By analyzing data and using predictive algorithms, maintenance teams can proactively schedule maintenance and be prepared in ordering and taking along the required equipment before they go on-site, reducing the risk of unexpected breakdowns and minimizing downtime. Digital communication capabilities enable the prospect of adding more plug-and-play sensors (such as accelerometers or air quality sensors) to support additional diagnostics and troubleshooting, identifying the root cause of the issue. This can help expedite repairs or even address a situation without a technician traveling to the site. The Gen360TM system also comes with cameras, such as the under-car camera, to support situational awareness and sensing to support additional mechanic safety.

Digitalization has also drastically improved the passenger experience. The Gen360TM platform, as with other Otis systems, can be outfitted with touchless systems through the Otis eCallTM app that allows a person to call the lift using their mobile phone. The Gen360TM system also provides integration with other Otis systems such as Compass® 360, the destination-dispatch system that can be integrated into the physical access control system of a building. Innovative technologies and faster communication have also made it possible to personalize video and audio content inside the lift car, while providing a more human touch to a distressed passenger in the case of an unfortunate situation such as entrapment. The eViewTM in-car display provides a unique live video link option so an entrapped passenger can speak to a live person, thus delivering the much-appreciated human touch at a time of distress.

4. Cybersecurity and Secure Product Development Life Cycle

As digitalization of connectivity of lifts increase, it is important that all efforts are taken to mitigate the risk of cybersecurity events or attacks from bad actors (or even “drive-by” hackers). The Gen360TM platform and its associated components are designed with cybersecurity in mind. A secure-by-design and defense-in-depth philosophy is at the core of the Secure Product Development Life Cycle (SPDLC) process that is at the core of product development at Otis and was followed during design and development of Gen360TM hardware and software. This process establishes cybersecurity as a design requirement right from the get-go. The process starts with a comprehensive understanding of the threat scenarios that define the overall security requirements using a risk-based methodology. This is followed by a methodical secure architecture design where different types of security controls/countermeasures are factored into product design to minimize cyber risk. Through subsequent stages of secure coding, static code analysis, open-source analysis, vulnerability analysis and penetration testing, the SPDLC leverages industry best practices to ensure that the required cybersecurity posture is achieved. Trained personnel verify that appropriate security measures are incorporated into the product, and the product is tracked for new vulnerabilities that may be discovered. Otis’ processes provide robust governance with checks and balances throughout the development life cycle. This process aligns with the internationally recognized IEC/ANSI/ISA 62443-4-1 standard and indeed, Otis has obtained external certification of its SPDLC process to this standard.

Apart from a robust process, the Gen360TM platform incorporates industry standard security controls and a number of key cyber technologies. This includes the use of secure boot technologies and code signing of software and updates to ensure that the integrity of the software is maintained. Any kind of external communication is authenticated with commensurate factors. Two factors for authentication where required. Additional layers of data encryption or signing are used to protect key data inside the various key components of the lift systems, including the PESSRAL nodes. These security controls are in alignment with the new ISO 8102-20 standard. Manufacturing of the components also goes through various security controls.

In addition to these industry-standard processes and controls, the SPDLC process also recognizes that the field of cybersecurity is continuously evolving, and new attacks and vulnerabilities are being discovered. Consistent with industry best practices, Otis has a product security incident response process (PSIRP) to provide ongoing cybersecurity support of our products post-deployment, including avenues to accept reports of potential incidents/vulnerabilities and a team to effectively manage the response. Any changes that need to be made to remediate vulnerabilities are carefully tested before going through a carefully planned effort of installing updates where required.

5. Sustainability

The world is more aware than ever of environmental challenges. This section will explore the meaning of sustainability and its importance, and how it has been considered in the design of the Gen360TM platform.

a) What is “sustainability” and why is it important?

Sustainability involves fulfilling our human needs without compromising future generations’ ability to do the same.

There are six factors of sustainability: climate change, environment, innovation, technology, people and ethics. Climate change tops almost all sustainability lists, as it is one of the biggest challenges faced by our planet today. It started due to the excessive GHG emissions caused by the burning of fossil fuel to generate energy.

The current global warming trend is at a rate that hasn’t been seen in numerous recent millennia. Scientists believe it is because of the heat-trapping characteristic of GHG since the mid-19th century.[5]

Sustainability provides countless benefits to individuals and businesses. One easy way we can change our sustainability level is by designing sustainable lifts and lift components that go beyond existing environmental regulations.

b) Environmental Regulations

Ecology, climate, social systems and business practices vary from country to country, so there isn’t a specific mechanism on how environmental sustainability should be practiced.

c) The European Green Deal[6]

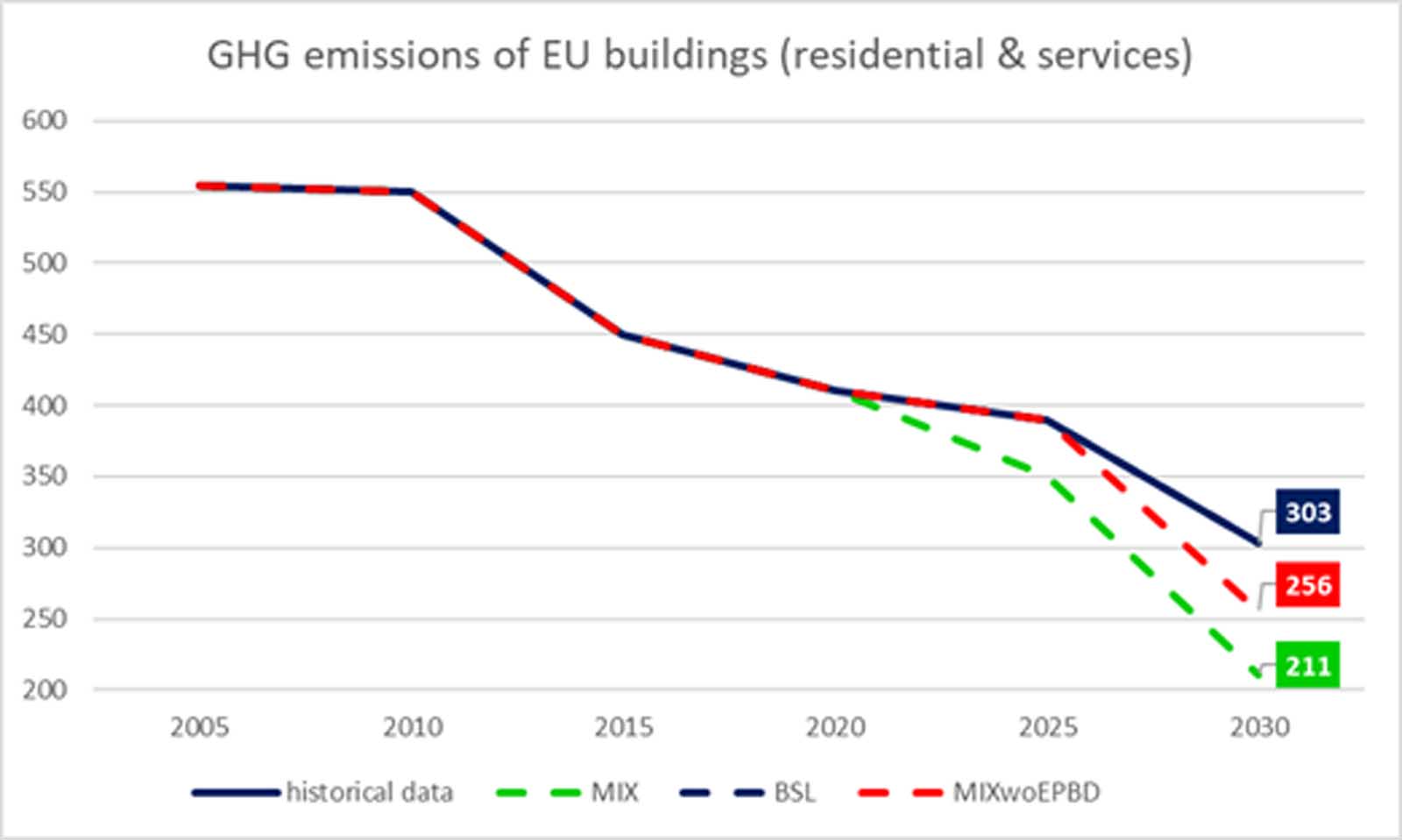

The European Commission has adopted a set of proposals to make the European Union’s climate, energy, transport and taxation policies fit for reducing net GHG emissions by at least 55% by 2030, compared to 1990 levels.

The EU aims to be climate-neutral by 2050 — an economy with net-zero GHG emissions. This objective is at the heart of the European Green Deal and in line with the EU’s commitment to global climate action under the Paris Agreement.

The building sector is the largest single energy consumer in the EU, responsible for approximately 40% of energy consumption and 36% of CO2 emissions in the EU. It is estimated that lifts consume between 2% and 5% of the energy of buildings. The lift industry can, therefore, contribute to decarbonizing the built environment by providing energy-efficient solutions and reducing the carbon emitted during the production of materials.

Therefore, various initiatives and schemes have been put in place to help achieve this difficult task, e.g., recovery and resilience.

To boost energy performance of buildings, the EU has established a legislative framework that includes the Energy Performance of Buildings Directive 2010/31/EU (EPBD)[8] and the Energy Efficiency Directive 2012/27/EU (EED).[13]

The Importance of EPBD to Lifts

Revised in 2018, the EPBD will help reach the building and renovation goals set out in the European Green Deal. Together, the directives promote policies that will help achieve a highly energy-efficient and decarbonized building stock by 2050 and create a stable environment for investment decisions that enable consumers and businesses to make more informed choices to save energy and money. The EPBD is the main legal instrument in the EU for improving buildings’ energy performance.

Lifts, escalators and moving walks are not part of the directive, but the European Lift Association is working with EU policymakers for inclusion and contribution to the EU’s ambitious goals. In this context, the use of Life Cycle Assessment (LCA) is playing an important role in upcoming national regulations within EU member states, with LCAs for buildings becoming mandatory, as well as Environmental Product Declarations (EPDs) for building products. The EPBD comprises the requirements on embodied energy and carbon footprint calculation for buildings. These calculations are obtained through the LCA and presented in the Environmental Product Declaration (EPD). Several member states are looking to set limit values on the Global Warming Potential (GWP) in CO2 equivalent per m2 and using LCAs as an instrument for policymaking or to measure the environmental impact of buildings.

While in absence of any legislative regulations regarding energy efficiency on the European level, in recent years attention has been paid by industry to the energy performance of lifts. The International Organization for Standardization published international standard EN ISO 25745 with a methodology to assess the energy efficiency of lifts and a scheme for rating their energy class. Finally, LCA is an important aspect for lifts, as they have a long technical lifetime. Product Category Rule (PCR) PCR UN CPC 4354 was elaborated on in 2015 and sets forth the rules for lifts that are either new or modernized.

How does the Gen360TM platform contribute to sustainability?

The Otis sustainability team has adopted the LCA approach for evaluating and identifying the relevant environmental impacts of the lifts, e.g., Gen2® lifts and considered observations/conclusions as key drivers for designing the Gen360TM platform. All the results have been reported in the EPD that can be consulted in the International EPD System.[12]

The LCA evaluation of the previous lifts helped reimagine the concept of the new lifts and its components and the way the digital transformation could support making this design more sustainable. Therefore, the engineers began by addressing the following question: How do we make the old-fashioned lifts more environmentally sustainable?

The design of old lifts was mainly focused on capacity, i.e, the number of people that lifts could carry. It was believed that the more people the lift could carry, the better the operations. But, this required more energy to produce and operate, and hence had a much greater impact on the environment.

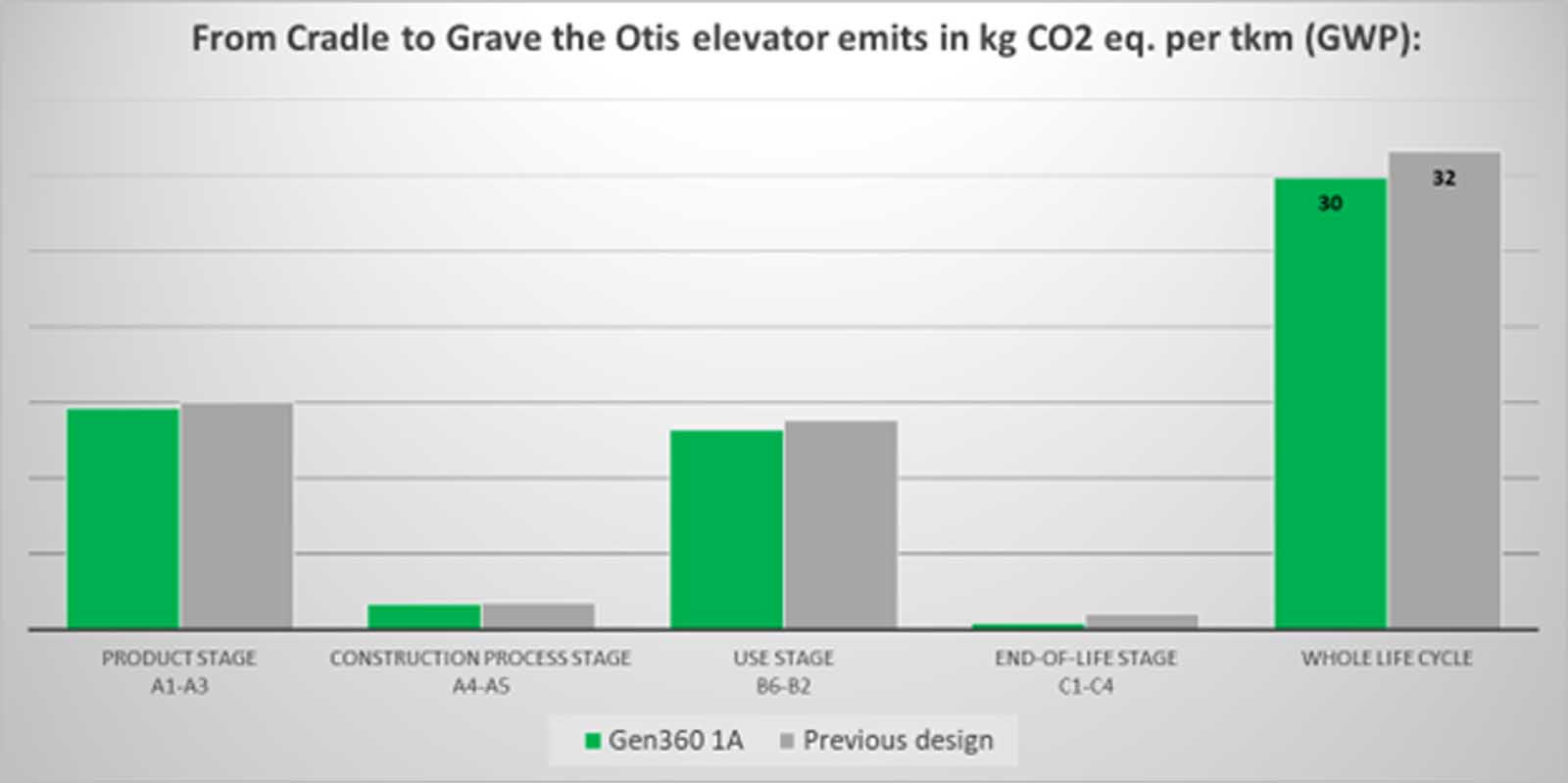

The LCA results reveal that the production and use phases have the highest impact on global warming.

Following the study, a set of design options was identified and prioritized by Otis. The major impact on environmental parameters is related to energy; changes in other environmental parameters entail only rather small changes in terms of material usage, compared to the overall mass of the lifts.

The design of the Gen360TM platform has focused on lower energy consumption, as well as sustainability and construction of the lift itself.

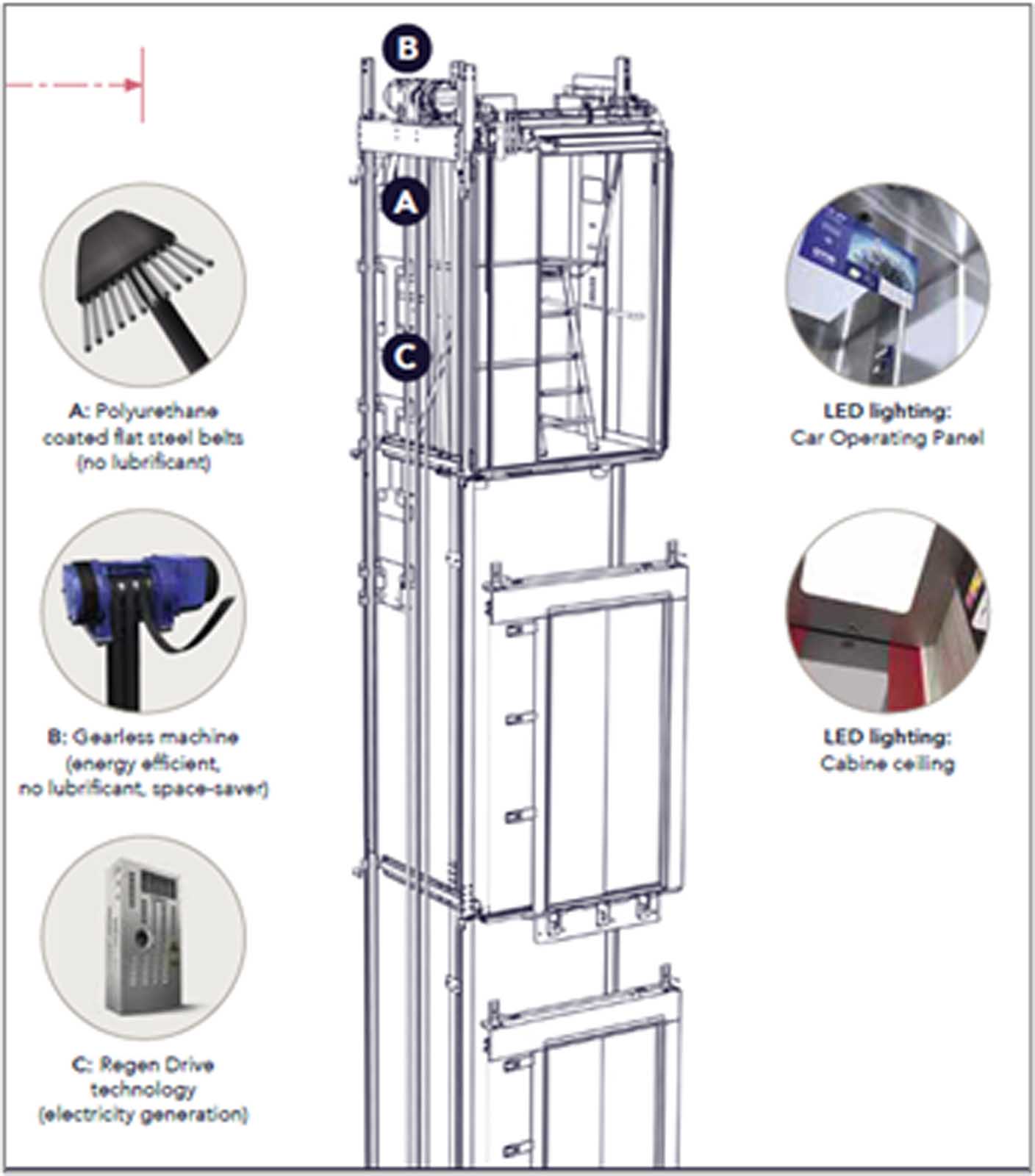

Based on the findings of the first LCA results and the Ecodesign preparatory study for lifts implementing the Ecodesign Working Plan[9] 2016-2019, in combination with the advanced methodology using Finite Element Analysis, the Gen360TM platform considered many of the following design features to reduce the environmental impacts (mainly the energy consumption) and optimize the mechanical structure:

- Low energy equipment: landing and car indicators and buttons, high efficiency LEDs for lighting, energy-efficient power supply and low consumption controllers

- Switch-off components: Light curtains, door controllers, lighting, ventilation and interior displays are switched off and panels are dimmed after 5 min of idle time.

- Deep standby: Energy consumption is reduced after 30 min without the lift being used. It reduces the consumption by putting the controller and the drive system in a deep sleep mode that will affect the response time to a call.

- Machine: In running consumption, the efficiency of the permanent magnet synchronous (PMS) gearless traction machine and other aspects of the drive system (including inverters), as well as the counterweights in the case of traction lifts, are optimized.

- Friction is reduced with Otis coated steel-reinforced belts. This innovative suspension means technology is also appreciated for its replacement rate compared to conventional steel ropes.

- Regenerative drive technology: A built-in energy-recuperation unit is utilized. It regenerates the energy produced by the lift and returns it to the grid mix. This green electricity can be used either for a building’s equipment or for lifts lighting. Energy consumption is reduced in the running mode, achieving energy savings as high as 75% compared to a conventional system with a non-regenerative drive.

- A new door operator decreases the energy demand in running mode.

- Use of Variable-Voltage, Variable-Frequency (VVVF) drives facilitates lower power consumption during the busy operation of a lift. In case of a multi-facility building, lifts work in a group operation.

- To encourage environmentally responsible forest management, at minimum of 50% of certified wood-based products, such as the wood paneling in the cab, are utilized.

- REACH compliance: Low-emitting materials, paints and coatings minimize the quantity of indoor air contaminants

- Predictive maintenance enables reduced transport to client sites, meaning, on average, less fuel is required and, consequently, reduced CO2 emissions. In addition to that, digitalization helps increase the reparability rate of components, thus reducing non-justified waste.

- The Gen360TM platform’s new electronic architecture has substituted most of the mechanical parts, leading to an optimization of the total weight of the lift, which means less energy needed to move the lift in the shaft.

As a matter of consequence, the Gen360TM platform yields better LCA results and the highest level of energy classification per ISO 25745 compared to previous studies.

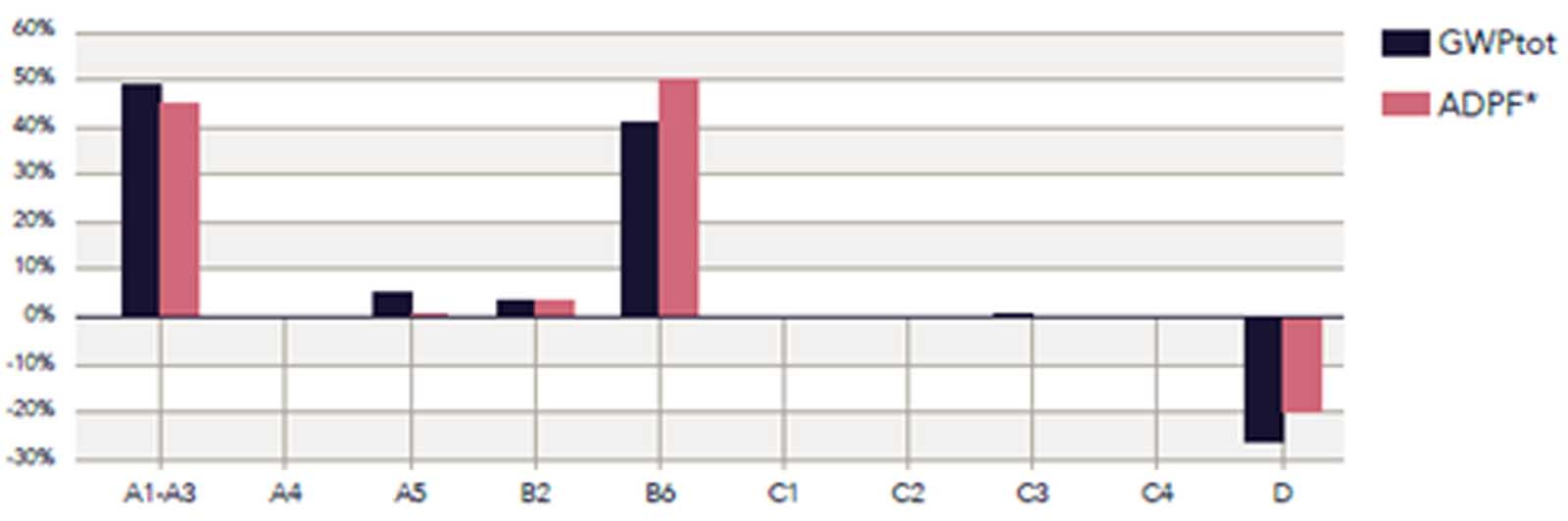

The impacts of the Gen360™ platform are driven primarily by materials manufacturing, i.e., A1-A3, creating approximately 50% of the GWP total and by the electricity consumption during use stage (25 years) with almost 40% of GWP. Comparison with the previous lift design reflects the progress made in sustainability with the Gen360TM platform.

6. Conclusion

To meet ever-increasing demand from customers and motivated by the increasing pace of urbanization, Otis has launched the Gen360TM platform, ushering in a true digital revolution for the lift industry, coupled with environmentally sustainable technologies. It leverages a native electronic architecture and a vast array of digital devices and processes with new safety and security features to further improve service, revitalize the customer experience and continually achieving greener solutions. This was made possible through the holistic approach of an international development team, leading to a completely reimagined Otis digital vertical mobility system platform.

7. References

[1] United Nations, Department of Economic and Social Affairs, 2018, revision: population.un.org/wup/publications/Files/WUP2018-Report.pdf [2] United Nations, “Report of the UN Economist Network for the UN 75th Anniversary Shaping the Trends of Our Time,” September 2020 [3] Urbanisation du monde, Espace-mondial-atlas.sciencespo.fr, September 28, 2018 [4] McKinsey & Company, “Thriving Amid Turbulence: Imagining the Cities of the Future,” October 11, 2018 [5] blog.cleanhub.com/environmental-sustainability [6] commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal/delivering-european-green-deal_en [7] “Achieving ‘Net Zero’ for the Lift Industry — Is It Possible?,” ela-aisbl.eu [8] energy.ec.europa.eu/topics/energy-efficiency/energy-efficient-buildings/energy-performance-buildings-directive_en [9] eco-lifts.eu/eco-lifts-en/content/documents.php [10] Understanding IEC 62443, iec.ch/blog/understanding-iec-62443 [11] ISO 8102-20:2022 Electrical Requirements for Lifts, Escalators and Moving Walks — Part 20: Cybersecurity, iso.org/standard/78576.html [12] environdec.com/home [13] rehva.eu/eu-policy/energy-performance-of-buildings-directive-epbd8. Acknowledgements

The Gen360TM platform is the exceptional achievement of hundreds of colleagues at Otis Elevator Co. By writing this technical paper, the authors’ objective is to represent them and promote the fruit of their work.

Get more of Elevator World. Sign up for our free e-newsletter.