The Happening: The Effects of New Zealand’s Earthquake

Mar 1, 2011

A glimpse into the impact the 2010 earthquake had on New Zealand and its elevator industry.

by Bob Johnston, EW Correspondent

Christchurch, New Zealand, has been home to me and my family for 24 or so years, after crossing the Tasman Sea from Hobart in Australia. My mother always warned me about potential earthquakes, and even after traveling in New Zealand without incident, my mother’s fear always remained.

Fear has always interested me because of how much of a role it plays in life, affecting everyone differently. On September 4, 2010, at 4:35 a.m., it called to those who live on the 43.3° south parallel in Christchurch, disturbing deep slumbers with a rising noise, followed by a forceful earthquake reaching a magnitude of 7.1 on the Richter scale (ELEVATOR WORLD, December 2010). I quickly became fully awake and aware. I soon realized there was no immediate collapse of the house around me, and I remember thinking it was probably best to remain in bed. On the other hand, my wife Jan was out of bed and downstairs before I realized she was frantically searching for a flashlight and battery radio.

What seemed like minutes turned out to be only about 40 seconds of uncontrolled movement, combined with sharp jolts that shook the windows, and for us, brought some things to the floor (but, interestingly, broke nothing). After the wild ride (and being in the dark), my response was to try to sleep until first light.

The Effects

Brick chimneys fell through the roofs of some houses. In the downtown part of the city, streets were covered with bricks after building walls collapsed; some local streams had disappeared; some houses had cracked and sunken floors; and geysers of soil oozed into backyards, streets and even through the floorboards of some houses. This sort of damage took place only 5 km from my home.

And so the heartache began: some buildings were unfit to live in, historical businesses needed to be relocated, high-rise tenants had to temporarily relocate while interiors were refurbished, sewer systems in some areas needed to be realigned, drainage systems had to be re-laid, and roadways had to be repaired. And yet, one could land at the airport and drive across town and not know an earthquake had taken place unless one stumbled into specific areas of the city.

The Effects on the Lifts

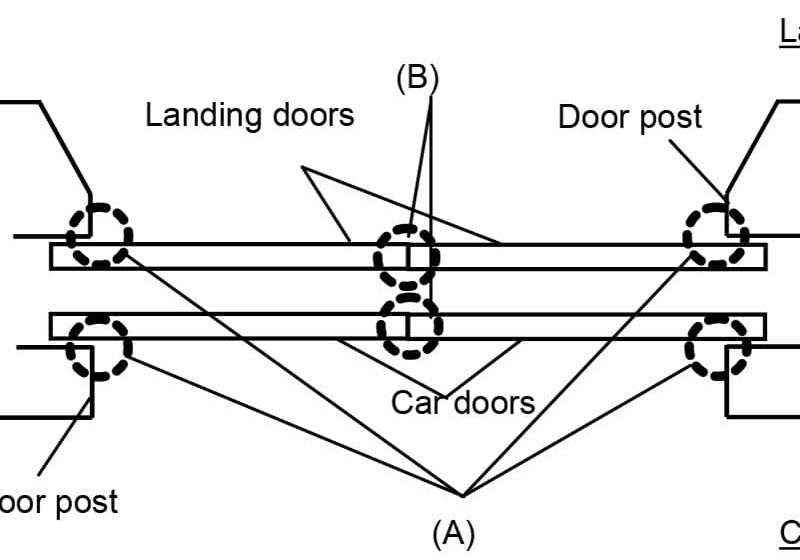

How did this earthquake impact the city’s lift industry? Since it happened on a Saturday morning, most people were in bed, and fortunately, not a single loss of life was lost. The majority of lifts were stationary and parked at the ground level of their buildings when the earthquake struck. Since there was no weekday rush of commuters, there was enough time for the center of the city to be closed off, allowing minimal access to buildings.

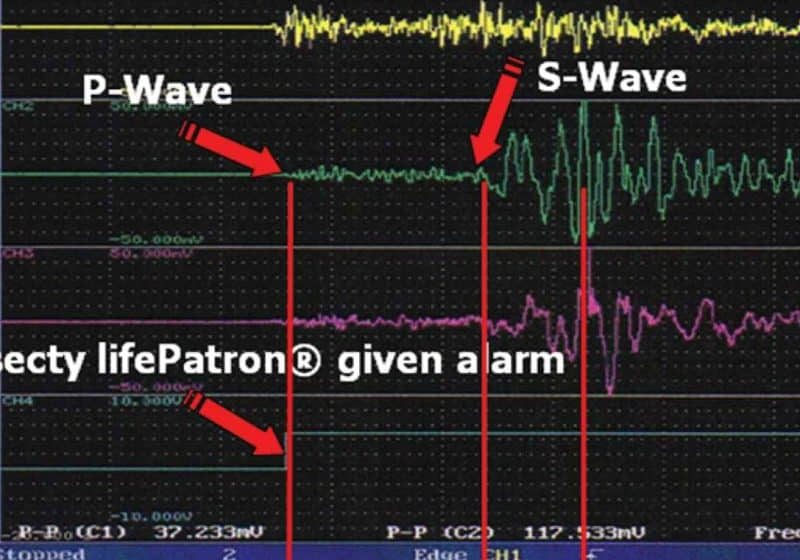

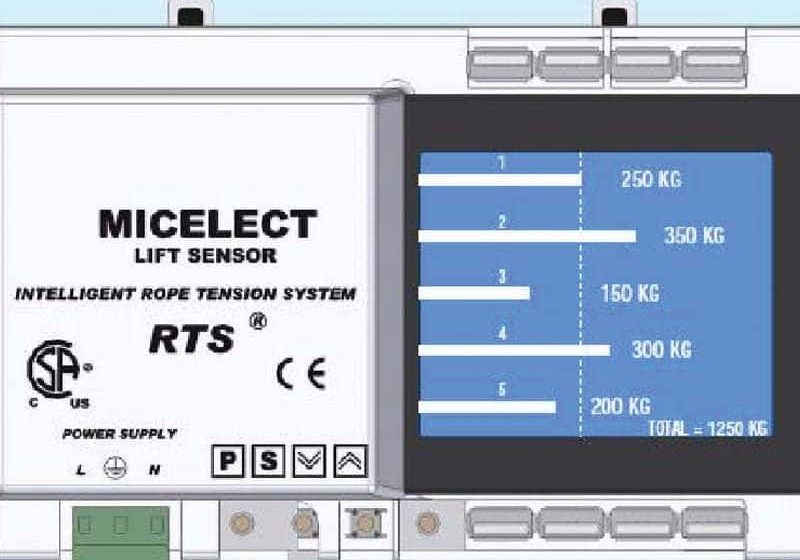

Since the 1980s, earthquake codes have included counterweight displacement sensors fitted on all buildings with over 15 m of travel. These were not only found to activate with counterweight displacement, but in practice, seemed to also trigger through aftershock building sway with magnitudes over 5.0, counterweight displacement.

To try and quantify the impact of this earthquake in the first few weeks, a survey of lift service in Christchurch was conducted.

It is obvious that the effect on the lift industry in Christchurch was relatively minor and could be handled by the infrastructure in the city. The effect on building users varied, with the biggest inconvenience being lifts shutting down from aftershocks reaching magnitudes over 5.0. This caused displacement of detectors, requiring them to be checked and reset. This was not due to counterweight displacement, but by building sway.

The 30 displacements of the counterweights from the initial 7.1 magnitude earthquake mainly reflected a larger bracketing span or general weaker installation practice, as all could be easily remedied through strengthening and/or reducing counterweight rail support spans. I think it’s fair to say that the earthquake reflected inconsistency in installation and, probably, inspection. The main reasons for low damage were the time and day the earthquake happened, the locking down of the central city and the efforts of lift companies and emergency services to check all lifts before clearing buildings for use.

The emergency services prohibited initial access to buildings downtown. It became part of the emergency services process only after the lift companies approached the emergency service control center to request that lifts not be used until cleared. Beforehand, they hadn’t thought of the ramifications of people entering buildings and using lifts, creating additional damage. The outcome may have been very different if the earthquake had happened during working hours.

The effectiveness of this lift design was mainly adopted for displacement of the counterweight from the guide rails in buildings with travel over 15 m. This might also suggest that it should be used as an earthquake detector for all lift installations in New Zealand. At present, upon initiation of the detector, the lift slows to the nearest floor and shuts down with its doors open, and a mechanic is required to check the site and reinstate the lift.

There were no persons entrapped by lift failures in the initial earthquake. However, over the following two weeks, 15 entrapments, which were mainly due to typical

stoppages combined with a few related to the ongoing effects of the aftershocks, were reported. In addition, some ropes came off diverter sheaves, where rope retainers were defective. Lift shaft structures worked as designed, and other than the few failures already mentioned, longer stoppages were due to external elements, such as water entering the lift shafts, requiring repair or replacement of damaged components.

In generalizing the overall effects of the earthquake on the lift industry in Christchurch, it can be said that the design and codes in building construction have proven their worth, with no lives lost, damage kept to a minimum, and, other than some inconvenience to building users and service provider personnel associated with the need to check before reinstating automatically stopped lifts, the overall effect was not severe.

The lifts without sensors with their shaft integrity remaining relatively sound and with less than 15 m of travel rise would more than likely continue to operate. Although entrapment occurrences would be higher, it wouldn’t be drastically different under this magnitude of earthquake.

What We Have Learned

Little has emerged relative to suggested changes to codes and installation practices by the industry. Though, with the effectiveness of the displacement detector, the secondary added detection of building movement or sway in an earthquake might suggest that all lifts have this solution fitted to ensure that when a significant tremor happens, all lifts shut down until they are able to be assessed. This may need an emergency service procedure to identify critical buildings and notify lift service providers to inspect and reset the listed units.

Key points of this experience:

- Displacement detectors are location and magnitude specific in operation. Therefore, the effect of the earthquake varies significantly within the affected areas.

- Displacement detectors minimize the likelihood of entrapment of persons during an earthquake.

- Where the magnitude of an earthquake or unexpected operation is sufficient enough to displace the counterweight, it minimizes entrapment, as well as the significant threat to life and further damage of equipment.

- Automatic shutdown at the nearest floor minimizes potential entrapments and additional damage to equipment from earthquakes with a magnitude of 5 or higher.

- Emergency services need to have a procedure to enable quick and efficient assessment of damage to any lift through notification to service providers and authorization to enter buildings.

- Existing codes and industry practices are probably sufficient as they stand, with the consideration of fitting displacement detectors to all lifts.

Get more of Elevator World. Sign up for our free e-newsletter.