The History of Operatorless Elevators: Traffic Control Systems (Part Two)

Oct 2, 2023

by Dr. Lee Gray, EW Correspondent

The design team that introduced one of the first automatic elevator traffic control systems included Otis engineers David L. Lindquist, Edward L. Dunn and David C. Larson. The team completed its work in early 1925 (see part one of this article, ELEVATOR WORLD, August 2023), and the company launched an ambitious publicity campaign the following year. The campaign featured advertisements, articles and conference presentations — all of which contrasted this new technology with earlier operatorless systems and presented it as a symbol of the “modern era” of the 1920s.

The first passenger-operated elevators had employed a system whereby a passenger: 1.) pressed a hall-call button to summon the elevator, 2.) opened the shaft and car doors, 3.) entered the car, 4.) closed the doors, 5.) pressed the button corresponding to their destination, 6.) upon arrival opened the doors, 7.) exited the car and 8.) closed the doors. Thus, while “automatic” in that the car did automatically travel to its destination and stopped (more or less) level with the landing, the system required passengers to play a series of critical roles in its actual operation. Other limitations of this system were that accurate or level landings could only be guaranteed at relatively slow speeds, and that, when in use, the car was unavailable to other would-be riders as the car only responded to one call at a time. The invention of micro-leveling in the early 1920s solved the problem of achieving accurate landings at high speeds, and Lindquist, Dunn and Larson solved the problem of providing more efficient service — particularly in high-traffic buildings. An interesting stopgap solution for use in high-traffic buildings was the “dual control” system that consisted of a combination controller, permitting the use of either car switch operation or automatic pushbutton operation by means of a throw-over switch. This permitted the use of operators on the elevator during the morning, noon and evening rush hours and changing the machine over to automatic operation during periods of light service, thus, requiring part-time employment of only one operator.[1] These elevators also required an annunciator in the car that signaled stops to the operator, as well as the passenger’s desired direction of travel.

The system developed by Lindquist, Dunn and Larson quickly became known as “collective control” (sometimes referred to as collective automatic control). This label reflected the fact that these elevators automatically responded when a call was registered and “collected” all passengers traveling in the same direction. This system included one version that was designed for settings where passenger-operation met the building’s needs, and a second version was designed for settings where an operator was perceived to be needed. Common elements to both systems included micro-leveling, “up” and “down” hall-call buttons, hall signal-lights that indicated a car’s impending arrival, a floor-button control panel mounted in the car and a floor selector that registered calls and dispatched elevators to their requisite stops. Each system also employed the same basic traffic flow model, which dated back to the late 19th century. Frederick Hymans described this model as follows:

“Usually, a bank of from four to eight elevators serves the floor on which the passenger is waiting. In daytime these elevators run on schedule; that is, they are started at regular intervals and in rotation on their trips between the terminal landings. At any one time these elevators will be at various elevations in the building, some going up and some going down. To serve the waiting passenger, the car at the time nearest to him and traveling in the desired direction must stop for him. This is ordinarily accomplished by some form of signal system, actuated by the waiting passenger, that automatically picks out this particular elevator and signals to its operator by light or buzzer.”[2]

The typical “rotation” trip involved traveling from the car’s designated terminal floor (typically the lobby) to the top of the building and back to the terminal floor.

The first collective control elevators followed this operational pattern, with cars automatically reversing direction at the landing furthest from their terminal floor and, if no additional calls had been registered, automatically “parking” at their designated terminal floor:

“This can be so arranged that during the morning hours the car will be ‘parked’ at the top of the hatchway, and after it has answered a call and picked up one or more passengers and has stopped at the first floor to let them out, it will immediately, upon closing of the hatchway door, automatically return to the top of the hatchway, to be ready for the next call. This saves considerable time for the next waiting passenger. During the evening rush hour, the parking station may be transferred to the first floor, so that after the car has taken passengers up and the last one has left the car, it will automatically return to the first floor and be ready for the next call. In some of the larger buildings, where more than one elevator will be required, they can be so interconnected that both cars will answer calls, the automatic feature also preventing duplication of service, in that the second car will only be called into operation after the first car has received a certain number of calls, and will be automatically shut down as soon as the first car is able to take care of the calls registered … With the collective type of automatic control, each call will be registered on the controller, and if, for instance, the passenger is starting down from the eighth floor and calls are registered in the down direction from the fifth and third floors, the car will automatically stop at those floors in succession, when these intending passengers may also enter the car. Upon closing the gate, the car will then resume its trip, stopping at the first floor for which a button in the car has been pressed, as well as stopping at any other floor from which a hall button has been pressed.”[1]

An additional feature addressed the actions of the prospective passenger who, after pressing a hall-call button, changed their mind and walked away. When a car arrived, it waited a predetermined period of time (typically a few seconds) after which, if the doors had not been opened, it would automatically proceed on its journey. Lastly, these elevators employed a motor-generator set: An AC motor was used to power a DC generator that produced the power needed to run the DC motor that powered the elevator.

The passenger-operated collective control system, unlike dual control elevators, made no provision for an operator. Thus, it was a true operatorless system. However, its operation required passengers to follow the same eight-step process of earlier operatorless elevators. Of course, these elevators, with collective control, now met the needs of multiple riders at one time. No explanation was offered for the absence of power-operated doors, which were an option in the mid-1920s. It may be that the use of contemporary power door systems — without an operator present — raised safety concerns due to their relative lack of operational sophistication. Because passenger-operated collective controlled systems were typically not employed in high-traffic buildings, these elevators also employed a unique energy-saving strategy with regard to the operation of the motor-generator set:

“The motor generator is automatically started by the pressing of a hall button or upon a passenger entering the car. When it has attained full speed, the car will respond to the hall call or to the pressing of a car button. The motor generator will run continuously for a predetermined adjustable time after the elevator has completed its trip.”[4]

This serves as a reminder that energy conservation — and related cost savings — has always been an important factor in elevator design and operation. A related feature was a key-operated switch (typically mounted on the car control panel) that turned off the automatic round trip feature. This was employed in apartment buildings where there was “likely to be … intervals of very light traffic during which a round trip of the elevator is not likely to result in the serving of more than one passenger.”[3] When the switch was activated, the car would automatically park on “the last floor for which or at which a button has been pressed.”[3]

The absence of elevator operators was also consistently noted as a critical attribute of this system, with comments typically focused on cost savings and the perceived “bad” behavior of operators:

“One of the most important features of automatic elevator service to the building owner is the reduction in expense, due to the saving in salaries of operators … From the standpoint of the tenant, the automatic elevator provides better service, because it never loafs in the hallways and never forgets to stop at the floor, as is so often the cause of trouble with apartment house elevators where the operators are indifferent or inefficient.”[1]

A precise account of possible savings highlighted the typical pay-scale of operators: “Assuming two elevators and 24-h service, four operators will, in general, be required … a total annual operating cost of approximately US$4,000 attributable to operators alone.”[3] For context, in 1920, approximately 37% of American workers earned annual salaries ranging from US$1,000 to US$2,000.[4]

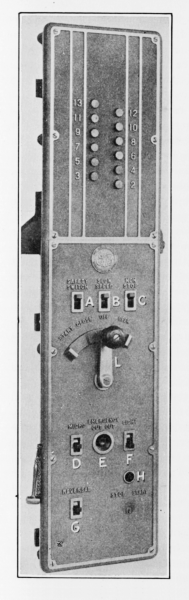

One of the key differences between passenger-operated systems and collective control elevators with operators was the use of power-operated doors. In operator-controlled elevators, when the car arrived at a landing, the doors automatically opened. In fact, the door operation began before the car came to a complete stop: “When a car arrives within a few inches of a landing they automatically begin to open and are fully open by the time the car has come to a stop.”[2] After passengers had exited and/or entered the car, the operator closed the doors by moving a lever on the car control panel. As soon as the doors were closed, the car automatically continued on its journey. Another operational difference concerned the motor-generator set. In a typical office building, it was common practice to shut down all but one elevator (which provided “night service”) at the conclusion of the business day. The car control panel included a locking switch adjacent to an indicator light (Figure 1). At the start of the day the operator would insert a key into the lock and turn it, thus starting the motor-generator set. When the system was “up to speed,” the red indicator light would come on, and the operator would remove the key. At the end of the day, the operator parked the car and turned off the motor-generator set, thus taking the elevator out of service.[5]

Otis’ advertisements for collective control elevators used phrases designed to capture the essence and excitement of this new paradigm:

- “Pushbutton high-speed transportation: Safer and surer than human hands and heads.”[6]

- “Otis Signal Control Elevators: For the highest class of Intensive Elevator Service.”[7]

- “Collective automatic elevator control elevators: For the highest class of Automatic Control without Elevator Operator.”[8]

Although they were not precise synonyms, Otis tended to use “signal control” and “collective control” somewhat interchangeably during this period. Otis also perceived this new system as being equal to other revolutionary technological developments:

“For many years, thinkers who watch mechanical progress with a friendly eye have asserted that the goal of machinery is to set mankind free from routine tasks, to give him time and opportunity for those tasks of the mind for which evolution has particularly fitted him. In two of our most important industries there have been recent developments, which may be truthfully said to have ushered in a new epoch. The dial telephone system, after years of experiment, has proved itself a practical and efficient servant of man. And the Otis Signal Control Elevator, also a product of untiring effort and experiment, marks a revolutionary step forward.”[6]

The connection between the freestanding dial telephone (introduced in 1919) and the automatic elevator, between an improved communication device and an improved elevator, strikes a familiar chord, given the perceived close contemporary connection between the modern “smartphone” and the increasingly “smart elevator.” While history does not repeat itself, it does, perhaps, occasionally produce an “echo.”

References

[1] “Automatic Elevators for Apartment Houses,” The American Architect (June 30, 1926).

[2] Frederick Hymans, Electric Elevators, Book II, International Textbook Company (1931).

[3] J. G. Morgan (Otis), “Push Button Control Elevators for Apartment House Service,” The Proceedings of the Twentieth Annual Convention of the National Association of Buildings Owners and Managers, June 13 to 17, 1927.

[4] Statistics of Income From Net Returns for 1920, Treasury Department, United States Internal Revenue, Washington, D.C. (1922).

[5] Fred A. Annett, Electric Elevators: Their Design, Construction, Operation and Maintenance, McGraw Hill (1927).

[6] Otis Advertisement, The Architectural Forum, July 1926.

[7] Otis Advertisement, The American Architect, December 20, 1926.

[8] Otis Advertisement, The Architectural Forum, January 1927.

Get more of Elevator World. Sign up for our free e-newsletter.