The perception that most elevator passengers have as they are riding our industry’s equipment is that the enclosure in which they are traveling is suspended from above. While in most large cities (and, in particular, downtown business districts) this is often the case, the fact of the matter is that in more cases than they realize, elevator passengers are being pushed from below. There are hundreds of thousands of existing hydraulic elevators in operation, and many more are being installed annually.

Nearly 25% of new elevators installed in 2010-2012 were hydraulic, and it has been reported that as much as 40% of the approximately 9.5-10 million existing elevators in the world may be hydraulic elevators. And, when you consider and compare hydraulic to traction elevators from a number of standpoints, the reasons for this become quite evident. When properly applied for the building in which they will be used for passenger and large freight transportation, hydraulic elevators provide a very cost-effective and simple operating elevator system. Numerous articles in this month’s Focus on Hydraulic Lifts and Components explain why this is the case.

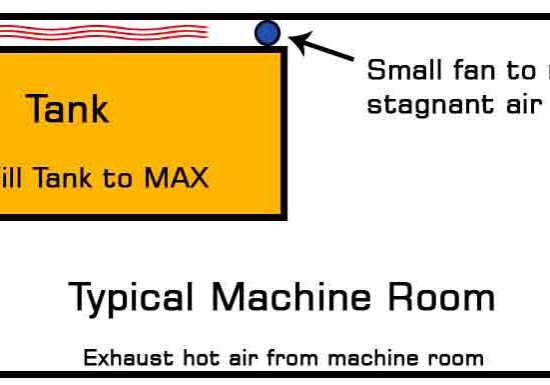

The article by William Shrum of Maxton Manufacturing Co. describes the importance of applying the correct hydraulic-elevator equipment for the project being considered. In this article, the proper placement of the pump unit in a well-ventilated elevator machine room, along with specifying and maintaining the proper oil viscosity during all phases of elevator operation, are pointed out as essential elements to maintaining good operation. And, when this is done, hydraulic elevators provide extremely cost effective solutions that will continue to provide excellent elevator service for many decades.

Energy efficiency and consideration of “cradle-to-grave” aspects of all building equipment are at the forefront of every construction project these days. In response to this, an article by Parag Mehta of Blain Hydraulics GmbH discusses applying variable-voltage, variable-frequency technology in conjunction with thorough lifecycle analysis of the latest hydraulic elevator equipment available in our industry. As Mehta points out, hydraulic elevators are often the best choice for many buildings.

Continuing with the consideration of the impact of elevator systems on the environment, Thomas Autcher of ThyssenKrupp Elevator has provided a description of the work his company has done to develop a readily renewable and biodegradable fluid that is 100% recyclable and meets all the needs of hydraulic-elevator operation. The always-important energy savings realized by using this product are also pointed out in the article.

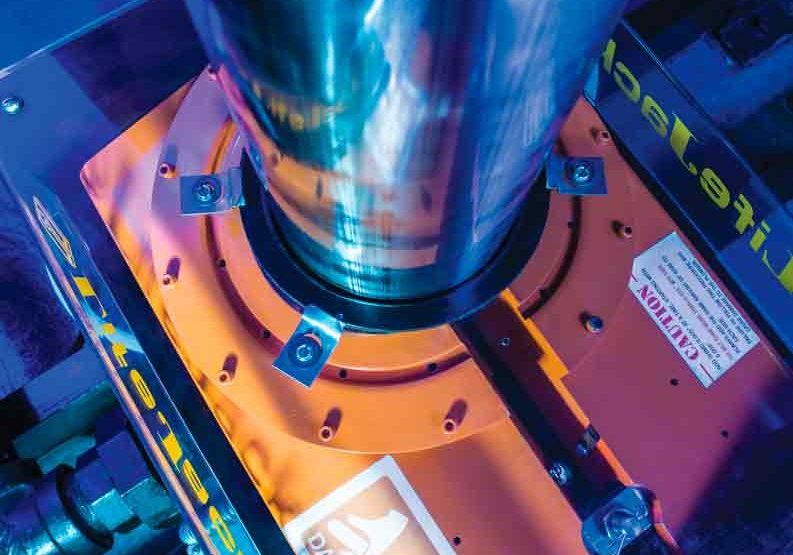

In his article addressing passenger safety, Gerald Adams provides numerous testimonials his company has received from elevator contractors that have installed the LifeJacket® plunger-gripper system. With as many as 3,100 of these devices having been installed since this product was introduced in 1996, readers will see that, as this article’s title states, the LifeJacket continues to support elevator passenger safety.

An additional article included in this month’s focus section describes Mongrain Vertical Transport’s latest MRL hydraulic-elevator product. The innovative design of this elevator system is described as being an ideal application for two-three-stop elevators, for either new installations or modernization projects.

When I was in the engineering side of the building-design and -construction business, one of our major architectural clients was fond of reminding us to implement the KISS principle (“Keep It Simple, Stupid!”) when developing our mechanical, electrical, plumbing and vertical-transportation system designs. When hydraulic-elevator systems are properly developed and applied, they fulfill this requirement. Whenever possible, look to your hydraulic-elevator suppliers for simple, cost-effective and environmentally sensitive vertical-transportation solutions. Elevator passengers don’t really care if they are pulled or pushed to the upper floors of buildings, just as long as their journeys are safe, secure and comfortable. Today’s hydraulic elevators fulfill these requirements, while properly responding to the environmental issues and concerns that must be considered on today’s projects – especially when the push is on to follow the KISS principle, which is always a very good idea.

Get more of Elevator World. Sign up for our free e-newsletter.