The Use of Nylon Pulleys in Elevators

Jul 1, 2012

The use of nylon for deflector and secondary pulleys, in addition to various code approvals for such components, is discussed.

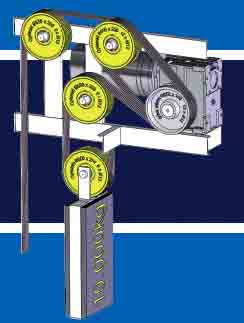

Pulleys made of steel have primarily been utilized for most traction-elevator applications, especially those with suspension wire ropes, traditionally and per code. However, since the 1970s, pulleys made of cast nylon-6 have been available and used as deflector and secondary pulleys. Originally sold in Germany by Neumeyer under the brand name Optamid, the product has been manufactured and sold by Schwartz Technical Plastics since the purchase of Neumeyer in 1995. Elevator Motors Corp. of Farmingdale, New York, has distributed the product for more than four years.

Since European jurisdictions were the first to approve and allow the use of plastic deflection sheaves, sales growth was initially limited to Europe. Currently, an estimated 55,000 Optamid pulleys are manufactured in Europe each year.

In the U.S., acceptance of the deflection pulley has been challenging. ASME A17.1/CSA B44, Paragraph 2.24, previously only allowed for steel sheaves, whether used for traction or deflection/secondary applications. There were no distinctions between traction or deflection/secondary applications; therefore, AHJs did not approve or allow pulleys to be manufactured of any material other than steel.

Eventually, ASME A17.7-2007/CSA B44.7-07, Performance-Based Safety Code for Elevators and Escalators was developed and provided AHJs with an objective and structured method for approving new elevator technology, while ensuring continued elevator safety. With the introduction and acceptance of this code in North America, plastic pulleys could be used for deflection/secondary applications if the manufacturer demonstrates its product meets global essential safety requirements and provides a risk-assessment analysis approved by an Accredited Elevator/Escalator Certification Organization (AECO). Currently, TÜV-SÜD, LiftInstituut and United Laboratories, Inc. are approved AECOs. Schwartz demonstrated its analysis in 2009 and became the second company in North America to be accredited with an AECO certificate for an elevator component. Optamid deflection pulleys are now in compliance with national codes and standards.

In addition, ASME A17.1-2010/CSA B44-10, Paragraph 2.24.2 now provides and allows plastic sheaves. The advantages of using deflection/secondary pulleys made from polymers include:

- Polymer sheaves are considerably lighter than steel sheaves. This makes installation easier and, if used on machine-room-less applications, decreases overall load, support-structure requirements, etc.

- Extreme rigidity, hardness and high impact resistance suitable for elevator applications

- Low friction resistance, making them quieter than steel sheaves and limiting wear on steel ropes

- Will not corrode

- Minimal maintenance is required.

- Increased rope life lowers maintenance and replacement requirements.

- Material is colored through in yellow for safety appearance.

Optamid materials can also be used in other elevator applications requiring chain sprockets, V-belt pulleys, etc. similar to those used on door operators and other elevator mechanisms. While Optamid or polymer pulleys cannot be used as traction sheaves, there are various applications for elevators. With code acceptance and product benefits, usage is likely to increase.

Get more of Elevator World. Sign up for our free e-newsletter.