The series conclusion examines the end of the unique system’s run and its mark on history.

One of the most intriguing hydraulic-elevator systems developed in the 19th century was the water-balance elevator. Parts one and two of this article (ELEVATOR WORLD, August and September 2017) examined the origins of this system in Boston and the Midwest U.S. during the late 1860s and early 1870s. This article concludes this story, tracing the use of water-balance elevators in the 1870s and 1880s, and defining their place in elevator history.

In February 1873, William E. Hale & Co. completed the installation of two water-balance elevators in the recently completed Hale Building in Chicago. The building served as a showcase for the elevator system manufactured by Hale, a fact highlighted in an article published in the Chicago Tribune. The article’s full title was “The Water-Balance Elevator: What Is Accomplished and Offered by the Baldwin Patent – An Hour With the Messrs. Hale.” It offered a detailed description of the elevator’s operation, as well as a comparison of this “new” system with existing steam-powered drum machines. A problem associated with the “older” technology was its noisy operation:

“There is more or less noise inseparable from the reciprocating crank movement, and the play of cogs, and in all cases the movement of the elevator is known by clatter and jar extending to all parts of the building. There are numerous first-class hotels, where the rooms adjacent to the elevator shafts are almost untenantable from this cause, and even the most perfect elevator of the ordinary kind is not entirely free from this objection.”[1]

The essential components of the water-balance elevator were: a water supply tank located at the top of the shaft, a water return tank located in the cellar or basement, a large “bucket” connected to the car via ropes that passed over a sheave at the top of the shaft, and a device in the car that allowed the operator to fill and empty the bucket. When the bucket was filled with sufficient water such that it weighed more than the car, the elevator would ascend; to descend, the operator opened a valve in the bottom of the bucket, and, when the car weighed more than the bucket, the car descended. The Chicago Tribune characterized the elevator’s operation as “the perfection of smoothness” and claimed that the “iron cables played noiselessly over the great sheaves at the top of the shaft.”[1]

By late 1873, Cyrus W. Baldwin, the inventor of the water-balance elevator, had moved to Chicago, and in 1874, the city directory described him as a superintendent with Hale & Co. A March 1874 account of an installation in the Lindell Hotel in St. Louis reveals that Baldwin’s responsibilities included overseeing elevator construction. The article also provides evidence of the dangers of elevator work:

“[On] Thursday, March 12, Mr. C.W. Baldwin, who was engaged in the construction of one of W.E. Hale & Co.’s water-balance elevators in the Lindell Hotel, had occasion to go up to the fifth floor in the car. The machine had not been finished and was not in use except for the purpose of raising material, but as Mr. Baldwin was accustomed to running it, he anticipated no danger. Unfortunately, however, the beam to which the tackle had been attached broke just as he got to the fifth story, and a piece of timber fell and stuck him on the head, inflicting a severe cut and felling him to the ground senseless. As he weighs 230 pounds and fell in a cramped position upon his right side with his leg under him, the muscles of the limb were very much wrenched and bruised. The car being detached from the frictions, which Mr. Baldwin had been holding, descended at its usual speed to the lower floor, where Mr. Baldwin’s condition was perceived by some gentlemen, who picked him up and asked if he was hurt.”[2]

The unfinished elevator was apparently operating with an open platform (without an enclosed car); therefore, riders had no protection from objects falling down the shaft. Fortunately, the hotel was only a five-story building; thus, the timber likely fell only a short distance before striking Baldwin’s head. The description of the car’s descent is somewhat at odds with the elevator’s typical operation, which required the operator to push down on a handle to release the brake. Additionally, Baldwin would have had to operate the bucket release valve to facilitate the car’s descent, something he could not have done if he had been “senseless” due to the blow to his head.

It is, of course, possible that the reporter was confused about the elevator’s operation. There was confusion surrounding the extent of Baldwin’s injuries. Although he had limped back to his St. Louis hotel with no difficulty, a local doctor, convinced that his leg was broken, insisted on applying a massive plaster cast before allowing Baldwin to return to Chicago. When he arrived in the city on Sunday, the cast was removed to reveal no broken bones, only a severe sprain. The success of his work in St. Louis is found in an account of the completed installation. A reporter described its operation as “much faster and smoother than those of which steam is the motive power.”[3] However, he also offered an additional observation, which reveals that its operation was not as quiet as the Chicago Tribune reporter had implied: “It is really frightful to listen to the rush and roar of the water as the elevator conductor places his foot upon the pedals of the cab and exhausts or receives the water into the buckets.”[3] This account, which described foot pedals used to control the flow of water into and out of the bucket, indicates that Baldwin continued to refine his design during this period. Previous models had relied on a shipper rope and lever to manage water flow.

The new control system was utilized in a water-balance installation that received national press coverage: the elevator installed in the Western Union Telegraph Building in New York City (NYC) in 1874. NYC press coverage of this elevator followed the pattern found in Chicago and elsewhere: emphasizing its unique characteristics and ease of operation. However, the account published in the New-York Tribune raises a few questions. According to the article, the Western Union Telegraph elevator was “the first water-balance elevator ever permanently used in New York.”[4] This statement implies that at least one of these elevators had made an earlier, temporary appearance in the city, although it provides no clues regarding the alleged earlier installation. The article also noted, “This elevator was patented a few years ago by Mr. Baldwin, a New England inventor. After undergoing considerable modifications, it has been extensively adopted in Chicago and other western cities.”[4]

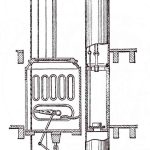

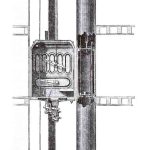

While a comprehensive list of water-balance elevator installations has not survived, a survey of newspaper accounts has found 24 installations between 1871 and 1885 (when Hale appears to have stopped manufacturing this system). Most of these installations were in the Midwest, thus confirming what was hinted at in the New-York Tribune article – that this elevator had a distinctly regional popularity. It did, however, often receive national attention. The 1880 edition of Appleton’s Cyclopedia of Applied Mechanics included a description of the water-balance elevator in the Western Union Telegraph Building, which had an accompanying illustration (Figure 1). Somewhat surprisingly, this illustration was a simplified version of an earlier image published in 1872 (Figure 2). In fact, the 1880 image omitted key components found in the earlier drawing and omitted the two foot pedals used to control the water flow into and out of the counterbalance bucket.

Given that stopping the elevator was solely under the control of the operator, a car traveling 1,500 fpm under these conditions was at its best exhilarating and at its worst terrifying.

Although the total number of water-balance elevators built may never be known, their presence was sufficient for them to have a distinct place in American popular culture. An 1886 article on elevator etiquette noted that their operational characteristics often caused passengers to forget about common courtesies, such as whether a gentleman should remove his hat when a lady entered the car:

“There are some other exceptions, however, in relation to elevator etiquette. One of such exceptions arises from the reckless rate at which some of the operators start and run their elevators. . . notably, those employed in elevators using the water-balance system, who are apt to become reckless. These elevators are started with such a sudden jerk, especially upon descending, that the passenger experiences a strong sensation of upheaval in his interior and a general sense of terror of what might happen through the mistake of the lad in charge, and has had all his thought of everything related to elevator etiquette driven out of his mind. Often when ascending, the car moves with such impetuosity that the passengers have the greatest difficulty in keeping from knocking against each other.”[5]

This vivid description runs counter to the “perfection of smoothness” found in the 1873 Chicago Tribune account of the elevator in the Hale Building. Adding to the potentially unsettling ride was the fact that these elevators were among the fastest in the 19th century. In 1889, Engineering and Building Record offered the following assessment:

“The fastest elevator probably now in existence is the water-balance elevator in the Western Union Building. This machine can attain a speed of certainly 1,000 fpm and probably 1,200 fpm. Similar ones in Chicago, not now in use, are reported to have reached 1,500 fpm.”[6]

Given that stopping the elevator was solely under the control of the operator, a car traveling 1,500 fpm under these conditions was at its best exhilarating and at its worst terrifying.

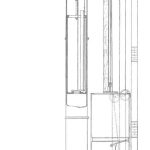

However, perhaps to the delight of many prospective passengers, Engineering and Building Record also reported, “This style of elevator is now no longer made, not being as safe as the more modern ones.”[6] Although the water-balance elevator was, by 1900, seen as a relic of a bygone era, it remained a subject of industry interest. In 1909, Otis included a description and illustration of a water-balance elevator in an article on historic hydraulic elevators published in its corporate magazine. The illustration was the most detailed drawing produced of this elevator type and provides insight into the elevator’s operation, including suggestions regarding the placement and working of the foot-pedal controls (Figure 3). Presumably, someone at Otis with firsthand knowledge of this “historic” elevator produced the drawing. Unfortunately, the draftsman’s identity is unknown.

However, the identity of one of the next persons to illustrate one of these elevators is known. In 1910, William Baxter, Jr. published the first edition of his book on hydraulic elevators. Included in this comprehensive work was a schematic drawing of a water-balance elevator (Figure 4). This simple (and, when compared to the Otis drawing, somewhat sad) little drawing marked the conclusion of the story of this elevator system. Baxter characterized the elevator as “a type that was used quite extensively in some of the large western cities some years ago” that, because of “the element of danger involved” in its operation, “never was looked upon with favor by eastern elevator experts.”[7] It was, of course, its potential for incredible speed (solely under the control of the elevator boy) and, perhaps, the associated danger, along with its simplistic mechanical system, that made the water-balance elevator one of the most memorable vertical-transportation systems of the 19th century.

- Figure 1: “Water Balance Elevator,” Appleton’s Cyclopedia of Applied Mechanics, Vol. 1 (New York: D. Appleton & Co., 1880)

- Figure 2: “The Hydro-Atmospheric Elevator,” The Industrial Monthly (April, 1872)

- Figure 3: “Some Historical Hydraulic Elevators,” Otis, The Indicator, 2, No. 4 (April 1909)

- Figure 4: William Baxter, Jr., Hydraulic Elevators: Their Design, Construction, Operation, Care and Management[7]

References

[1] “The Water-Balance Elevator,” Chicago Tribune (February 16, 1873).

[2] “Local Miscellany: St. Louis Surgery,” Chicago Tribune (March 25, 1874).

[3] “Fire Escapes,” St. Louis Post-Dispatch (April 20, 1877).

[4] “A Novelty in Elevators,” Philadelphia Inquirer (July 24, 1874) (reprinted from New-York Tribune).

[5] “Elevator Etiquette,” The Des Moines Register (July 3, 1886) (reprinted from Chicago News).

[6] “Elevator Speeds,” Engineering and Building Record, 19, No. 17 (March 23, 1889).

[7] William Baxter, Jr., Hydraulic Elevators: Their Design, Construction, Operation, Care and Management (New York: McGraw-Hill, 1910).

Get more of Elevator World. Sign up for our free e-newsletter.