Well-attended events provide a wealth of information about products, safety and the state of the global industry in vibrant, progressive South Korea.

South Korea evokes images of Hyundai and Kia cars, LG appliances and Samsung mobile phones. Kimchi has become a popular dish in international circles, and followers of pop music are well aware of South Korean star Psy. It is certainly common knowledge that two sovereign nations occupy the Korean Peninsula: The Democratic People’s Republic of Korea, usually referred to as North Korea, and The Republic of Korea, a.k.a., South Korea. The two countries are separated at the 38th parallel by the 4-km-wide Demilitarized Zone. Most are also aware that the Korean Conflict exacted a heavy toll on the population of the peninsula. It ended more than 60 years ago with an armistice, not a peace treaty. Approximately 29,000 U.S. troops remain in South Korea to provide support if the country is attacked.

Many people in the West are aware of North Korea’s nuclear weapons programs and of its leader, Kim Jong-un. Fewer are aware of the recently elected, first female president of South Korea, Park Geun-hye, who stresses engagement and conciliation with North Korea. She vows to “pursue tangible South/North consultations to resolve the North Korean nuclear problem.” The South Korean government is structured as a well-developed constitutional democracy with separate executive, legislative and judicial functions.

[South Korea] is a clean, efficient, progressive-yet-relaxed country of some 50 million people, the vast majority of whom enjoy a good standard of living.

A visit to South Korea is, indeed, an eye opener. It is a clean, efficient, progressive-yet-relaxed country of some 50 million residents, the vast majority of whom enjoy a good standard of living. Approximately 60% of the residents live in apartment buildings, a proportion that is one of the highest in the world. The availability and standard of healthcare are among the highest in Asia, and job security is very favorable. There is a strong emphasis on education at all levels, and the percentage of young people with tertiary degrees is one of the highest in Asia. It is not surprising that South Korea is a very innovative country and a positive environment for conducting business.

With a robust economy and a high rate of economic development, it follows that South Korea has a vibrant elevator industry. It is a credit to the progressive thinking of its citizens that the first elevator was installed in the Bank of Korea building in Seoul more than a century ago. Since then, the population of tall buildings has grown rapidly, to the point where the installed elevator base exceeds 500,000 units, and over 30,000 units are being added each year.

Your author attended the third International Lift Expo Korea 2014, which included the International Lift Safety Seminar.

Lift Expo Korea 2014

Lift Expo Korea was held at the COEX Center in Seoul on October 28-31, 2014. The event was organized by the Korea Elevator Safety Institute (KESI), an affiliated public organization of the Korean Ministry of Public Administration and Security, which was the event’s sponsor. Ian Todkill, president of the Pacific Asia Lift and Escalator Association (PALEA), was the expo’s honorary chair.

The expo was opened by Kong Chang-seok, president of KESI and chair of the expo organizing committee. Kong welcomed dignitaries and attendees, then mentioned this was the first Lift Expo Korea to obtain the endorsement of the Global Association of the Exhibition Industry (UFI). This indicates the country’s elevator industry is regarded as an important international player. He also said the purpose of the event was to promote the elevator industry and public safety.

Lee Song-ho, vice-minister of Safety and Public Administration, emphasized the commitment of South Korea’s government to public safety and commended the elevator industry for its efforts to enhance safety at all levels. He also endorsed the industry as a whole for its innovative spirit. Several other dignitaries, including Todkill, added to these strong messages. Todkill observed that the input of South Korean delegates to PALEA had greatly strengthened the organization’s credibility and capability.

The Expo

The exhibition hall was filled with high-quality displays representing the latest in elevator technology. The major players in the domestic market — Hyundai, Otis, ThyssenKrupp Elevator and Mitsubishi Electric — were there in force, and dozens of small to medium-sized manufacturers of elevator systems and components from both South Korea and around the world displayed their wares to a global audience. The knowledge base of representatives in the various booths and exhibits was impressive. Their insights into the technology behind their products and their willingness to share information were refreshing.

Some of the interesting items featured included:

- Hyundai’s NEW YZER machine-room-less (MRL) elevator, which is intended to minimize hoistway space requirements. Hyundai displayed elevators with speeds up to 10 mps. Such elevators deploy active roller guides to enhance ride comfort.

- ThyssenKrupp Elevator’s Mini synergy, an MRL elevator designed to carry four passengers, intended for installation in small buildings. Also featured was TWIN, comprising two elevators in a single hoistway.

- Otis bridged the past, present and future with its depiction of Elisha Graves Otis at the Crystal Palace at the 1864 World’s Fair in New York City, while displaying its energy-efficient Gen2® MRL system using coated steel belt (CSB) suspension. Otis also emphasized energy-efficient regenerative drives.

- Mitsubishi Electric emphasized green technologies, showcasing double-deck elevators and units with speeds up to 18 mps.

Some of the smaller companies also had interesting exhibits, such as Kumbo with its inclined elevators, which can accommodate slopes of up to 75° with a variety of cable and hydraulic drive systems. Also on display were Higen’s motors and traction machines, and Haisung’s mini elevator cabs and speed-reduction units. A plethora of controllers, transducers, simulators, interface units and dispatch systems were also showcased.

Children at the Expo

It was very inspiring to witness wave after wave of elementary school students who visited the expo. A special room was set aside where teachers and industry experts met with the children and explained the basics of elevator and escalator operation and emphasized the need for safety. Models of elevator systems created by older children were on display.

The children were introduced to an educational program called “My Friend, the Elevator!” An elevator safety-education kit for elementary school students was handed out to teachers. The kits contain a CD and full-color, illustrated guidebook for teachers, as well as full-color, illustrated textbooks for students. The kit also includes 3D puzzles that can be assembled to form elevators and escalators, as well as leaflets on escalator safety.

The students were deeply absorbed by the contents of the lesson and seemed to enjoy the experience. Of course, the hardhats the children received added to the fun! The kit and course material were developed by KESI in consultation with school authorities. Course contents are intended to be delivered by teachers through the school curriculum, rather than by external volunteers, as is the case in similar programs in other parts of the world.

International Seminar on Lift Safety

The International Seminar on Lift Safety was an important part of expo activities. It was organized by Choi Il-sub, KESI general manager, Department of Internal and International Affairs. The seminar was chaired by Todkill and was intended to provide an overview of how elevator safety issues are being addressed around the world.

Todkill spoke on the topic “Harmonization of Worldwide Lift Safety Standards.” He summarized progress made over the last 20 years in the rationalization and harmonization of prescriptive standards in many parts of the world. While there were dozens of different standards two decades ago, today most standards are aligned with one of the three mainstream ones: CEN EN 81, ASME A17.1/CSA B44 and the Building Standard Law of Japan/JIS Standards. The major driving force for harmonization is the enhancement of safety coupled with the globalization of the world’s economy. Todkill also described the efforts that have taken place over the years under the International Organization for Standardization (ISO) umbrella to promote convergence of all elevator standards. He described the current initiative aimed at developing an ISO prescriptive standard.

The next speaker was Harry Vyas, technical director, New York City (NYC) Department of Buildings, Elevator Section, who addressed the topic “Lift Safety Policy of NYC.” Vyas described the unique nature of NYC in terms of diversity of equipment with respect to age and technology. Indeed, NYC is a mirror of elevator evolution over more than a century. Vyas described the process of standards development and adoption in NYC, and the process of managing and training inspectors. He also described the organizational structure of the Elevator Section and how it is configured to implement the policies of the Department of Buildings. Vyas also spoke of initiatives to enhance the safety of older elevators, which constitutes a large proportion of NYC elevators.

The overall quality of the exhibits, technical presentations and general organization was first class, and the emphasis on education and innovation augers well for the future of the South Korean elevator industry.

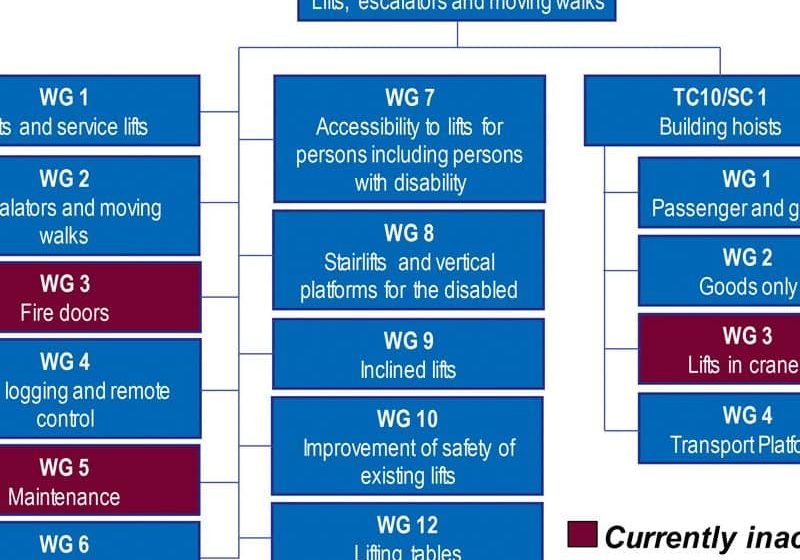

The next speaker was Esfandiar Gharibaan, chair of CEN/TC 10, who addressed the topic “Lift Safety System of Europe.” Gharibaan elaborated on the spectrum of standards under the purview of CEN. He discussed the process of achieving consensus under CEN rules in Europe. Gharibaan also explained the Lifts Directive, including the Essential Health and Safety Requirements, as well as the Conformity Assessment process. He explained how EN 81, as a European harmonized standard, could be used to satisfy the requirements of the Lifts Directive, which is a law in Europe. Gharibaan described the process and content of the new EN 81-20/50 code and emphasized that experts from South Korea, China, Japan, the U.S. and PALEA helped in its development. It is anticipated that this standard will be widely adopted around the world.

Your author was the next speaker and addressed the topic “Elevator Safety Code of North America.” This provided an opportunity to review the evolution of buildings since 1860 and the role elevators have played in this process. A pictorial representation of early building construction was presented. It is noteworthy that more than 60 years passed from the time of demonstration of the first safety elevator to the publication of the first elevator code by a consortium of manufacturers. The first consensus-based code was published in 1921. It was only 50 pages thick and evolved through 20 editions to the current, 500-page document. Evolution of the code was driven by expansion of scope to cover various modes of building-transportation systems, enhanced public expectations regarding safety and advancement of technology. Currently, a suite of codes and standards covering prescriptive codes, codes for existing elevators, performance-based codes that facilitate innovation while ensuring safety, suspension-means standards, etc., are available in North America.

The next speaker was Zhang Lexiang, secretary general of the Chinese Elevator Association (CEA), who addressed “Lift Safety System and Lift Industry of China.” Zhang described the process of adopting and enforcing safety standards in China. China is a large country with many jurisdictions, and much diversity in culture, economic development and population concentrated in cities. The adoption of standards requires consensus at many levels and government approval. Enforcement is centrally mandated and locally controlled. China has a rapidly expanding economy, and its cities are developing at an extremely rapid rate. The demand for elevators keeps increasing such that approximately half of the world’s new installations are in China. With such rapid development, safety is of paramount concern, and the CEA, the Elevator Safety Board, the enforcing authorities and the government continuously review safety requirements.

The next speaker was David McColl, convener of ISO Working Group 4 and leader of the Canadian delegation to ISO. McColl addressed “Evacuation in Building Emergencies.” Traditionally, building occupants were instructed to use the stairs, rather than elevators, during emergencies. However, with the advent of increasingly taller buildings, it is not practical to use stairs as the only means of emergency egress. McColl described the process for occupant evacuation operation (OEO) included in recent versions of A17.1/B44. It was developed by a diverse team of experts, including first responders, who used hazard analysis as a tool. OEO includes such features as water diversion, water-resistant enclosures, redundant power supplies and special operational controls and dispatch functions. In the event of an emergency, the affected floor and two floors above and below are given priority. Dynamic signage that advises the public when it is safe to use affected elevators is required. For buildings that use OEO, trained floor wardens are required to assist occupants during emergencies.

The final presentation of the seminar was given by Achim Hütter, chair of VFA-Interlift. Hütter spoke of the rapid globalization of the world elevator industry and its effect on suppliers and users of elevator components, systems and subsystems.

The presentations were well received, and Kong closed the seminar with an expression of thanks and appreciation for the hard work and willingness of the presenters to share their knowledge and experience.

Concluding Thoughts

Lift Expo Korea 2014 and the accompanying International Seminar on Lift Safety were very well organized by KESI. The quality of both was excellent. The expo was well attended by both domestic and international visitors. The overall quality of the exhibits, technical presentations and general organization was first class, and the emphasis on education and innovation augers well for the future of the South Korean elevator industry.

Get more of Elevator World. Sign up for our free e-newsletter.