ThyssenKrupp’s headquarters complex in Essen, Germany, includes 21 elevators and three escalators.

Considered a symbol and the heart of the company, ThyssenKrupp Quarter in Essen, Germany, was inaugurated in 2010. It demonstrates structural change and economic renewal for the area, because previously, the site had been a hole in the urban fabric of downtown Essen for decades. The architecture was drawn by firms JSWD of Cologne, Germany, and Chaix & Morel el Associés of Paris, with a modern design objective to create a district with transparent and homogeneous architecture.

In the center of the campus-like area stands the 50-m-tall cube-shaped Q1. The design is composed of different volumes interconnected at angles around a large central atrium. The air space extending up to the glass roof has 700 1-m2 picture windows creating a fluid transition between the interior and exterior. Its cantilevered bridges and mezzanines simultaneously make use of the interior space. Building Q2 houses the company’s conference rooms, accommodating 1,000 people, a cafeteria, a visitors’ restaurant and the “Room of Tranquility.” In addition, the Quarter features buildings Q5 and Q7, all of which provide space for 520 employees, in addition to the 2,000 employees Q1 houses.

Constructed in compliance with strict requirements for utilization of resources and environmental sustainability, the Quarter is on car-free grounds. An underground parking garage allows for supplies and waste disposal to be delivered and picked up without being seen. The Quarter engages in additional sustainable practices. In 2011, the German Association for Sustainable Building awarded ThyssenKrupp AG its gold certificate for the company’s ecological and economical construction of its headquarters.

Vertical Transportation

ThyssenKrupp Elevator equipment was installed throughout the site and includes 21 elevators and three escalators. In Q1, ThyssenKrupp Elevator’s TWIN systems were installed. One TWIN system operates in its shaft on the west side, and on the east side, there are two shaftless elevator cars. A single elevator of the same design is located next to them. The elevators’ design gives one the impression they are floating as they glide against a backdrop of a stainless-steel façade. To implement the architects’ futuristic vision, the elevator cars were sheathed inside and out in a multitude of nearly seamless white glass panels.

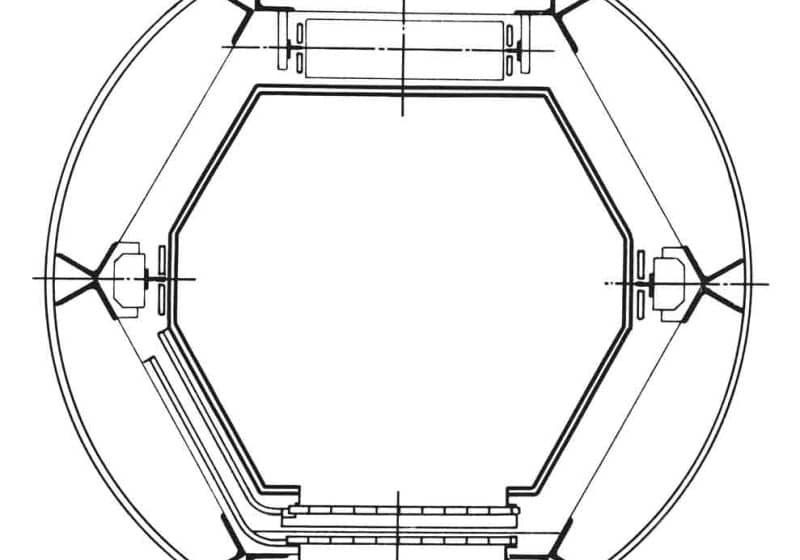

The interior trim is composed of single-pane safety glass provided with a rear-surface powder coating. The glass panels are of semitransparent mirror glass. A display similar to a taxi display was used for the elevators’ position indicators. The numbers and indications on the control display appear through the glass panels and give the impression of a projection. The floor and ceiling of the elevator cars are also made of glass, with a three-part LED backlighting system installed behind them. The white-glass concept includes car slings and all other cabin components. The glass exterior covering presented a challenge. Since a powder-coated surface cannot be glued (at least, not on the outside of an elevator car without a surrounding shaft), an enamel coating had to be used during assembly in order to ensure the strength of the supporting structure.

The floating elevator cars were not the architects’ only design vision. It also included designing the elevator cars without visible technology that would glide up and down along the wall with no visible means of propulsion. This meant eliminating the otherwise standard locking device with a door drive cam. However, simply eliminating them was hardly an option, since the elevator car does not have to open to transport passengers. The solution involved swapping the landing door on the ground floor with the car door on the rear side. The result was a TWIN system provided with only a single driven landing door. A limited-run series of car and landing doors was produced and assembled. To conceal the action of the mechanism, as well, the corresponding parts were enclosed in stainless-steel plates.

Q1’s elevators were equipped with a people counting system designed by Siemens AG. This served as the access-control system and is integrated into the elevators. Only authorized users are able to open the locked doors and access the underground parking garage and elevators. Radio-frequency identification technology was used for communication in the elevator cars, and the identification system recognizes only authorized users. Only then is a previously entered command enabled to set the elevator in motion. In addition, the shaftless TWIN systems and individual passenger elevators were grouped by means of destination-selection control.

With a total weight of more than 5 mT and a rated load of 1350 kg per elevator car, the cars travel at 2.5 mps and cover a maximum travel height of 45.7 m. The machine-room floor is constructed in the form of a “cantilever slab” and must be able to withstand a static load of more than 40 mT. The visible shaft is clad in stainless steel from the ground floor to the 10th floor.

An additional feature is the sunken stop provided for the TWIN system at the third underground floor, even though Q1 has two underground floors. To allow the upper elevator car to also serve the lowest stop, the lower elevator car of the TWIN system must be moved into the sunken stop. This is to ensure all three elevator cars can transport employees to their offices during peak travel times.

The designers also considered energy efficiency. In the TWIN system, the energy produced when braking the elevator car is converted into electrical power and supplied back into the power grid. Many of the systems are equipped with LED lamps, and nearly all of the elevator cars are equipped with a smooth pulley system. As a result, no oiled rails were required.

Get more of Elevator World. Sign up for our free e-newsletter.