Touch-free Elevator control Technology for Public Health

Jul 1, 2021

In this Product Spotlight, NZT’s HoverTap keeps VT users safe from pandemic dangers.

by Dr. Nima Ziraknejad, Pranav Saxena and Shaun Harper

The COVID-19 pandemic has placed unprecedented constraints on the way people move in open and closed spaces. It has redefined the way we interact with the environment, other people and even objects around us. At the onset of the pandemic, surfaces were among the first sources believed and confirmed to pose contamination risks. Face masks and gloves became common. And, while further studies and updates into surfaces were discussed, and some panic subsided, excessive handwashing, sanitization and minimal touch have become the new norm. In fact, health advisors still caution against frequently touching surfaces, especially in high-footfall and multi-user areas, such as elevators. Governments, commercial entities and individuals continue to spend vast amounts on deep-cleaning efforts. One study estimated that the global sale of surface disinfectants totaled US$4.5 billion by the end of 2020.[1]

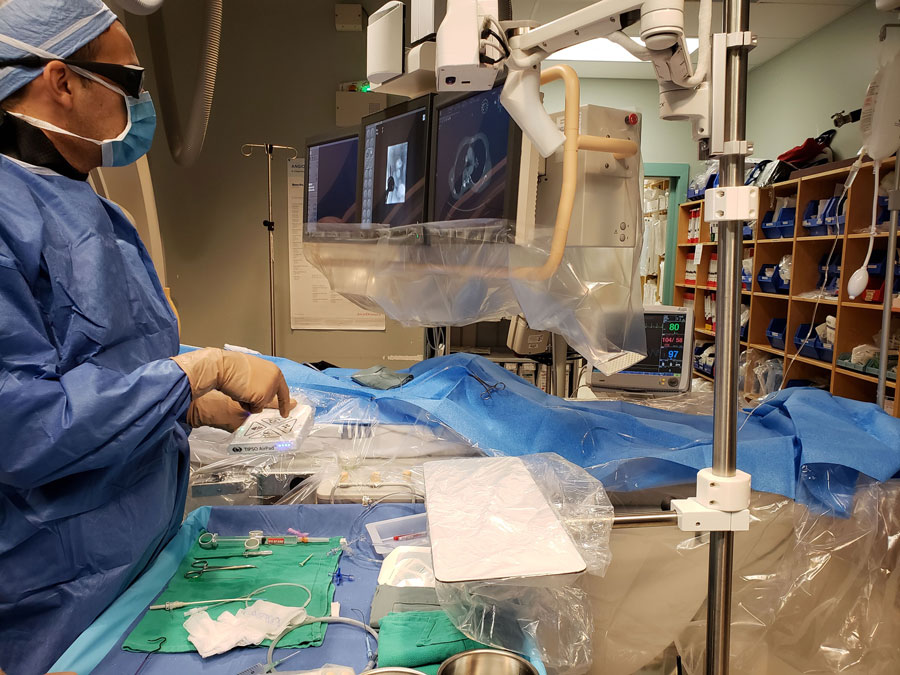

COVID-19 infection incidents have been traced back to elevators. In one study, an asymptomatic woman in China, who had recently returned from the U.S. and was quarantined at home, infected her downstairs neighbor through her building’s elevator.[2] NZ Technologies identified the challenge of elevator buttons early on and sought to deliver a solution that would simplify the lives of the general public so they could resume their day-to-day activities more assuredly. We recognized that our Touchless Image Navigation technology, initially designed to work within the sterile conditions of the operating room, was well suited for the vertical-transportation (VT) industry, especially elevators. We created HoverTap™, a technology we patented and commercialized, to transform any existing high-touch surface (such as elevator buttons) into a contact-free interface that protects users from the spread of infectious diseases.

Inspiring a Solution

Our core technology and inspiration behind HoverTap was based on a solution that we had invented specifically to address a pain felt by surgeons. Our patented TIPSO AirPad™ was developed six years ago in Vancouver, Canada, to minimize the risk of infections inside operating rooms. Using this unique device, surgeons became able to touchlessly interact with patient medical images during surgery without having the patient leave the bed or disrupting the surgeon’s workflow. With COVID-19, we recognized that our touchless technology has applications far beyond the operating room, making it especially suited for the post-pandemic world – a world that needs a new way of touchlessly interacting with high touch surfaces.

Touchless Interactions for the Everyday User

The patented HoverTap technology was carefully developed with the user’s experience in mind. Its two main components, a novel 3D capacitive sensor and an AI algorithm, can detect the 3D position of a user’s fingertip in real time. The sensor is in the form of a “picture frame” fitted over the high-touch surface in question. The sensor then senses the user’s fingertip, based on a data-trained AI algorithm, and determines its 3D location above the surface. One common implementation is a touch-free touchscreen (aka a touchless screen) in which touchless taps in the air can interact with virtual buttons on an LCD screen. Also, simple touchless gestures such as an air swipe can be used, for example, to quickly call an elevator or turn on a light.

HoverTap was designed to be simple and convenient to use – its intuitive interface is easy to grasp for new users. By tracking the user’s fingertip in 3D, with zero latency, it enables a simple point-and-tap action that feels like pressing a button. Additionally, this unique technology does not use a camera, which helps avoid common privacy concerns and also overcomes various issues associated with camera sensors (ambient lighting and visual obstructions). Additionally, HoverTap sensor hardware is affordable — it is made of common materials and easily installed.

The First Installation

The HoverTap sensor, by its very nature, can be retrofitted to existing elevators. As an auxiliary device, it doesn’t interfere with any existing buttons. The retrofit connection is simple — button signal wires are connected via signal relay switches, and the system is physically mounted beside the cabin buttons or directly over the hallway call buttons. We have collaborated closely with a local elevator service company, West Coast Elevator (WCE), and it has played an instrumental role in validating our sensor design to suit the unique demands of the elevator. Together, we’ve finalized the product’s design and defined a straightforward process for installing HoverTap inside elevator cabins.

HoverTap was well-received by early users, the public and the industry. The display is a dynamic interface that visually inspires confidence that the property is providing a safe environment for elevator passengers. It was met with strong interest from Ronald McDonald House in Vancouver— a respected institution that provides housing support for families with children in need of essential care. It was here that we installed the HoverTap Lift touch-free elevator solution for the first time as a commercially ready system. Also, the HoverTap Lift System is set to be installed at Richmond City Hall (Canada) in complete alignment with the Richmond City Council’s vision for a modern, energy-sensitive and environmentally-friendly building.

A Strategic Collaboration

NZTechnologies has entered into a Manufacturing Collaboration Agreement with Dupar Controls, a leader in the innovation, design and manufacture of elevator control systems and push button technology. As the original equipment manufacturer of HoverTap Lift, NZTech will provide the core hardware and Dupar will market the product under two models:

- A retrofit for existing elevator panels, and

- A panel-integrated solution for new elevator installs or overhauls.

The retrofit option allows for a budget-minded surface-mount without the need to replace the existing button fixtures, while the panel-integrated option incorporated into new button fixtures provides a premium finish for a luxurious installation. Systems are now being manufactured for five test sites in Ontario and British Columbia. With the combined expertise of NZTech as an innovator and Dupar as a manufacturer, touch-free elevator experiences will be available for buildings big and small.

Competitive advantages of HoverTap Lift include:

- Flat (non-protruding) design

- Simple touchless input (touchless taps and swipes akin to smartphones)

- Intuitive user feedback (detects user approach and input)

- Retrofittable to existing elevator cabins (working in parallel with existing buttons)

- No cameras involved (no privacy concerns)

Philosophy and Vision Forward

HoverTap is helping us get closer to our vision of increased comfort and control, with an emphasis on safety and peace of mind. Our tagline for the technology, “Bringing Touchless Interactions to the General Public,” motivated us to work tirelessly and provide the type of innovation that has put NZTech on the map as a leader in touchless technology. In fact, we see elevators as just the tip of the iceberg. Given how frequently we interact with touch-based interfaces in our daily lives, we hope the technology that took off in operating rooms and elevators will soon be rolled out into other applications, such as gas stations, bank machines and airport kiosks.

As we recover from the devasting impacts of COVID-19 and enter a post-pandemic era, NZT’s intuitive technology provides practical and easy-to-install solutions that decrease the risk of infectious diseases among the general public. While COVID-19 may have been a wake-up call for us to revisit how we go about our daily habits, it also provided an opportunity for technological evolutions, such as ours, whose sole purpose is ensuring public safety and wellbeing no matter where we are.

References

[1] https://www.nature.com/articles/d41586-021-00251-4

[2] https://www.businessinsider.com/coronavirus-jumped-between-people-via-elevator-surfaces-study-2020-7

Pranav Saxena, a professional engineer, is one of the founding inventors of NZTech’s products and more than 20-plus patents. He has built and trained a cohesive engineering team, driven product development and managed NZTech’s international regulatory/certification approvals.

Shaun Harper has 41 years of elevator industry experience as a mechanic, adjuster and in management positions. He was employed for 28 years in Winnipeg Manitoba before moving to Vancouver BC in 2008. He has been working for Vancouver-based West Coast Elevator for the last 13 years.

Get more of Elevator World. Sign up for our free e-newsletter.