Trends for Elevator Drives and Consequences for Safety Brakes

May 1, 2017

Keeping the safety factor of brakes high in the face of a changing drive market

This paper was presented at  Madrid 2016, the International Congress on Vertical Transportation Technologies, and first published in IAEE book Elevator Technology 21, edited by A. Lustig. It is a reprint with permission from the International Association of Elevator Engineers

Madrid 2016, the International Congress on Vertical Transportation Technologies, and first published in IAEE book Elevator Technology 21, edited by A. Lustig. It is a reprint with permission from the International Association of Elevator Engineers  (website: www.elevcon.com).

(website: www.elevcon.com).

The new elevator drive generation is designed to fulfill the latest market requirements. The market demands efficiency, and fast and compact drives. What are the consequences for the safety brake? We as brake manufacturers are confronted with updated parameters like speeds, higher-friction work and smaller dimensions.

All these parameters have an influence on designing the right safety brake. We have to ensure a reliable brake function over the lifetime of the elevator. This article identifies the most important new parameters that may influence the development or selection of a safety brake.

1. Introduction

Leading elevator companies are continuously setting new standards in the elevator industry. We, as a global leading brake manufacturer, have to follow the new standards and are forced to find solutions for the new requirements.

Obviously, the safety brake is one of the most important components for an elevator. The elevator market demands smaller, faster and cost-optimized drives. That leads to increasing requirements within a specification of leading elevator manufacturers. Some requirements are new or higher than they were in the past and have to be evaluated first. The brake has to fulfill the requirements over the lifetime of the elevator. There is no compromise on safety. Therefore, a proper qualification process, together with drive manufacture of new implemented brakes in the market, are mandatory. All new requirements must be checked in order to avoid any problem in the field.

On the other hand, we as a safety brakes manufacturer recognize that the elevator industry must be more cost efficient in order to survive in the aggressive market. So, we are confronted with the topics, “How can cost cutting be made safe? How does cost cutting affect safety?” One of the challenges that the elevator market faces is the difficulty reflecting the full effects of cost cutting.

Thus, a complete understanding of how cost and production pressure affect safety is important to be able to prevent the undesired effects that may arise. Cost cutting is necessary, but it should be done with caution.

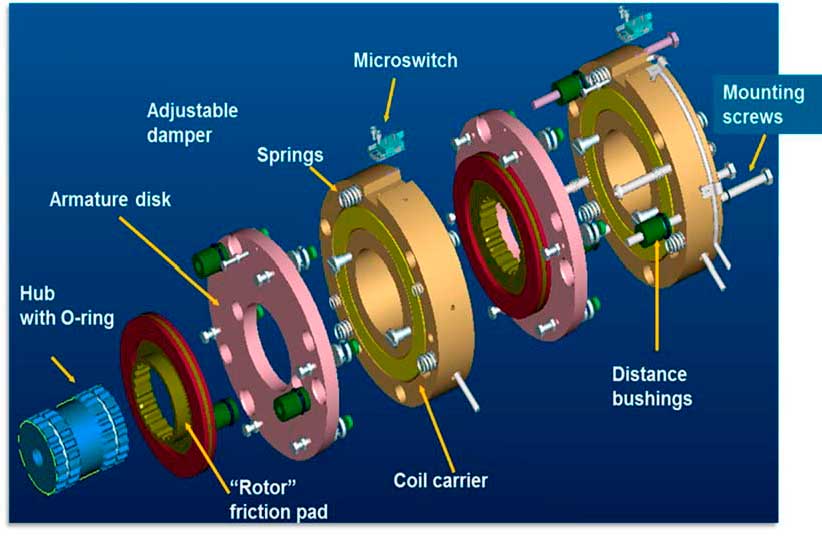

2. Elevator Brake

Today, safety brakes are an indispensable safety feature in modern elevator drives. We consistently take the following basic safety principles into account during development and manufacture: the electromagnetic safety brakes operate according to the failsafe principle; they are, therefore, closed in a deenergized condition. The braking torque is generated by the force stored in the thrust springs. If the magnetic coil is energized, a magnetic field is built up, which attracts the armature disk against the force of the springs, thereby releasing the rotor with the friction linings. The brake is released. This condition can also be achieved using an integrated hand release. The brakes developed for the elevator sector are mainly used as holding brakes but also take on friction work in case of emergency-stop braking actions.

3. New Requirements for Elevator Brakes

3.1. Higher Temperatures

The new generation of drives is more compact and designed for small elevator shafts. Higher power density can lead to higher temperature at the motor flange. A higher motor flange temperature has some effect on the brake.

3.1.1. Static Torque

Holding the elevator in position requires a certain static torque. Such torques must be provided under all ambient conditions and over time. The static torque will be influenced from cold or high temperatures. The ambient temperature plus smaller drives lead to a higher temperature than in the past. The high temperature may have some effect on the friction coefficient. Figure 2 shows that conventional friction lining can lose its friction coefficient at high temperature. The brake manufacturer has to develop a brake lining for high temperatures.

3.1.2. Micro Switch

Higher temperatures also have an effect on the micro switch. Temperature will lead to expansion of and change of the operating points of the switch. The smaller the air gap, the more difficult to find the right switching point. This may result in serious consequences. The brake manufacturer has to find the right balance between minimum stroke and air gap.

3.1.3. Switching Noise

Switching noises are basically nonexistent and lie below 50 dB(A) in new condition (sound pressure level measurement). However, with high temperature, the elastomeric system is stressed more than in the past. The noise level is not a safety requirement but can lead to claims in the field. Nevertheless, the dampening system influences the switching time. Under section 3.1.4., the relation between dampening system and switching time is explained.

3.1.4. Switching Time

A constant switching over the lifetime is essential in order to fulfill the requirements of A3 (extension of the EN 81-1). The brake has to supply a reproducible switching time in order to calculate the right stopping distance of the elevator car. The dampening systems have an influence on the switching time. As already mentioned, the temperature has a major influence on the aging of the dampening system. There are dampening systems on the market where aging or destroying the dampers can lead to a longer switching time. The worst case could be that the elevator car cannot be stopped within the right distance because of switching times that are too long. The difference lies in the detail. All brake components have to be dimensioned safely and made of high-quality, known and proven materials. Furthermore, brakes should be equipped with a reliable dampening device. Switching times are basically low when new. Long-term tests confirm that operation switching time levels remain low even after 300,000 switching actions. Even after several million switching actions, the switching time is still substantially below the level of other elevator brakes.

3.2. Higher Speed

3.2.1. Higher Friction Work

The static brake torque is to hold the elevator car, but in the case of an emergency, the dynamic brake torque is important. In the case of an emergency, the brake has to engage quickly in order to reduce the acceleration of the car.

The new drive generation is working with higher speeds. That leads to higher friction work within an emergency case.

Friction values mentioned in the latest specification show higher values than in the past. Standard friction linings may not be able to work properly with the higher-speed torque. The reason is the high temperature on the friction surface that reduces the friction coefficient. The reduction of the friction coefficient during the brake action can be critical. It may happen that the brake is not able to decelerate the car. The brake manufacturer has to find a friction material with a stable behavior even during excessive friction work.

3.3. New Generation of Belt-Driven Elevators

3.3.1. Brake Torque Tolerance

New compact elevator drives, in combination with modern elevator belt-driven drives, rise to a challenge for brake manufacturers. The brake moment tolerance became an important specification.

There is a simple reason. Classic rope elevators have a different behavior during emergency brake action than elevators with belt-driven drives. What is the difference between rope and belt drives during an emergency brake action related to the brake? If the brake torque is too high, the rope will slip on the traction sheave. The traction between belt and traction sheave is higher. The belt will not slip on the traction sheave. The full deceleration goes directly to the car. The worst case could be that the passengers of the elevator can be injured during dynamic brake torque due to the high brake torque or, rather, high deceleration.

The main parameters affecting the brake moment tolerance are:

- Spring force

- Constant friction coefficient of the brake lining

- Proper break-in of the brake system

- Roughness and structure of the friction surface

- Temperature

The parameter with the most important influence on the friction parameter is the behavior of the friction lining. What we need is a friction system with constant behavior under all different conditions in order to fulfill the brake torque requirements.

4. Which Tests Are Required in Order to Fulfill the New Requirements?

On one hand, we have to think about how to fulfill these new requirements. On the other, we have to also talk about how to save costs. We have the ability to test all new requirements, considering cost cutting. Some brake manufacturers are making the brake smaller and smaller without considering all requirements. Making the brake smaller means cutting the safety factor of the system. If you do that, you have to be sure that you fulfill all new requirements. We have several testing devices like a climatic chamber, flywheel test bench and partial friction lining test bench. How can you be sure to fulfill all these requirements without the right equipment? If you bring a new, cost-optimized brake into the market, all critical conditions have to be checked.

4.1. Flywheel Test Benches

With the flywheel test bench, you can test brakes under real-life conditions. You can change speed and mass. We, as a brake manufacturer, are able to test different speeds with different inertias. This is important for the evaluation of the switching times, the wear of the friction-lining static and dynamic brake torque. These tests are also important in order to be sure not to exceed the maximum brake torque.

4.2. Climatic Chamber

In the climatic test chamber, we can test the brake under extreme conditions. In combination with the flywheel test bench, we can test brakes under all environmental conditions like influence of the temperature (high/low) on static and dynamic friction coefficients.

4.3. Partial Friction Lining Test Stand

With the partial friction lining test stand, we can test the friction coefficient across different batches.

5. Conclusion

New elevator applications have new requirements for brakes. Brake performances differ from old application conditions. Elevator brakes and friction technology are very complex subjects, with many criteria that may influence the result. That must get enough attention. It is highly recommended to choose a brake manufacturer with a lot of experience. In this day and age of cost cutting, a reliable brake supplier with the ability to test all new requirements is essential. For a qualified manufacturer, there is no compromise on safety. I work for a company with the philosophy “one accident is one too many.” Keep your elevators safe with a reliable brake manufacturer.

- Figure 1: Elevator brake

- Figure 2: The influence of temperature on static torque of a certain lining material

- Figure 3: Micro switch changes over temperature

- Figure 4: Switching time changes over lifetime

- Figure 5: Reduced friction coefficient during excessive friction work

- Figure 6: Possible friction lining behavior during friction work

- Figure 7: Friction lining test bench

Get more of Elevator World. Sign up for our free e-newsletter.