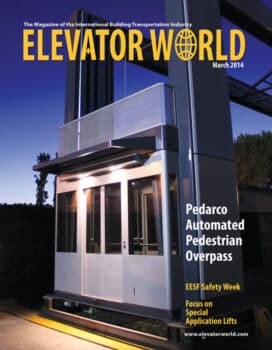

Pedarco’s automated pedestrian overpass aims to provide a solution in a quickly urbanizing world.

Pedarco International Ltd. hopes an idea born in Italy and developed in China will result in smoother, safer travel for pedestrians crossing heavily trafficked roads and other areas in rapidly urbanizing locations worldwide. The company’s product is an automated pedestrian overpass in which an enclosed cab traverses a steel, inverted C-shaped structure. It consists of an elevator cabin that travels vertically, passes horizontally over a road, railway or waterway, then is lowered again. Its name, “Pedarco®” is derived from the Italian words for “pedestrian,” pedone, and “arch,” arco. Explains inventor Tarcisio Scomparin:

“Pedarco is a solution whose automation, lack of steps, ramps and pathways distinguishes it from other solutions. It is a unique solution that works for all types of pedestrians, including the handicapped. Pedarco is not just an elevator moving between floors, but a real vehicle to move people and things over obstacles. It is destined for use by persons with walking disabilities, children and the elderly in particularly dangerous, high-traffic areas.”

Headquartered in Hong Kong, Pedarco International Ltd. is a joint venture between Pedarco srl and Anlev Ltd. (www.anlev.com) formed to develop and market the product. Anlev has escalators in theme parks, airports, rail and metro stations, and supermarket chains worldwide.

Construction on Pedarco’s manufacturing facility, on 77,157 m2 of land in China, is entering the home stretch. By the end of the year, the plant aims to produce, deliver and install its first system for a city government in rapidly growing Hunan Province, China. The manufacturing center’s capacity is estimated at one system per week. Pedarco’s principals have been showcasing the concept to the world community at trade shows. Its reception was enthusiastic at Interlift in Augsburg, Germany, in October 2013, Scomparin said. “Ideas, questions, thoughts and suggestions have confirmed the project’s guidelines and strategies for market development,” he stated. Pedarco plans to host a booth at Asia Pacific Rail 2014 on March 18-20 in Hong Kong.

Geographically, Pedarco has set its sights on China to start, but aims to enter other markets, such as India, in approximately three years. According to Pedarco, the most promising markets are those with strong urban growth, and where sentiment is favorable to vulnerable segments of the population, such as children, the elderly and the physically disabled. The same analysis showed a strong interest in markets enthusiastic about innovation and luxury. Scomparin discusses the strategy:

“Traditionally, Europe represents the forefront of market innovation and luxury. However, most European countries are still suffering from the economic slowdown. Pedarco’s major customers, therefore, are government and public organizations like railway and subway operators, which rely on public funding. We believe, in the short term, that developing countries offer better opportunity for Pedarco.”

R&D took approximately three years, and Scomparin said there were several engineering challenges to overcome, including how to:

- Maximize capacity and speed

- Ensure active and passive safety

- Reduce energy consumption

- Minimize size to prevent intrusion on surrounding architecture and landscape elements

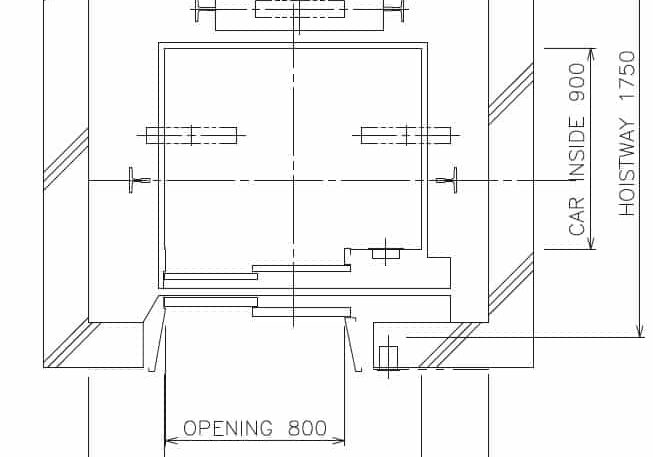

Many of Pedarco’s components are in the process of attaining patents. Price varies depending on individual project requirements and characteristics. Components are designed to be shipped in standard-sized containers. The cabin of the initial commercial model, Pedarco 14A, has a capacity of 1650 kg, or approximately 20 people. Tempered glass starts approximately 70 cm. from the bottom. The panoramic (and, therefore, ideal for claustrophobic passengers) cabin measures 2.4 m wide, 1.4 m deep and 2.15 m tall. It can easily accommodate items such as bicycles, wheelchairs and baby carriages, the company notes. The support structure on which it travels is made of electro-welded steel components forming a pair of parallel arches placed perpendicular to the road, water or railway. The structure’s appearance can be customized. Scomparin elaborates:

“The outer parts and the structure are mostly made up of panels that can be replaced, painted or modified without affecting the system’s functions. The structure itself, given the small size [its footprint is approximately 1.9 m x 4.6 m] and clean design, can be easily inserted within specific architectural envelopes. In this way, for example, you can create navigation routes for pedestrians between buildings or structures such as car parks, gardens, etc., separated by roads.”

A balance system used to raise the cabin is able to recoup a significant amount of energy, which the company says reduces consumption by up to a third compared with a traditional elevator with similar capacity. Pedarco’s structure can also be outfitted with signage, advertising or solar panels. Pedestrian access to the cabins is via stations located at the base at each end of the arch. Stations may be placed on the interior or exterior of the arch, and more than one station may be incorporated into vertical runs, allowing access at different levels such as in a train station.

Power and movement control systems are located within the support structure, which further streamlines its footprint. The cabin moves continuously, with acceleration, top speed and brakes electronically controlled. Targeted maximum speeds are 0.6-1 mps on the vertical leg of the trip and 1.5-2.5 mps on the horizontal leg. An average trip takes 40-55 s.

Standard security equipment, such as emergency phone and alarm, is similar to what one finds in a typical elevator. In the event of a power outage, a battery-powered system ensures the cabin returns automatically to the ground. The cabin is outfitted with two ladders and a service/emergency gangway alongside the arch, allowing for quick evacuation. It also has side-opening panels and a roof hatch. Options include:

- Station and cabin video cameras

- Personalized finish

- Electric-power generating photovoltaic panels

- Cabin air-conditioning and heating systems for melting snow

- Traffic-light interfacing

Safety was a focus throughout R&D, Scomparin states. When the cabin is running vertically, the European norm EN 81 is applied, for example. Pedarco foresees needing to adapt to various country-specific requirements as its business grows. For worldwide sales, Pedarco’s strategy calls for partnerships with sales and maintenance companies related to Pedarco, such as those specializing in lifts and escalators, Scomparin said. If all goes well, Pedarco will become an essential road-infrastructure component, “similar to elevators and escalators inside buildings.”

Get more of Elevator World. Sign up for our free e-newsletter.