Upgraded Style and Monitoring

Dec 4, 2021

New solutions improve lift cars and general service.

EASE Cabin

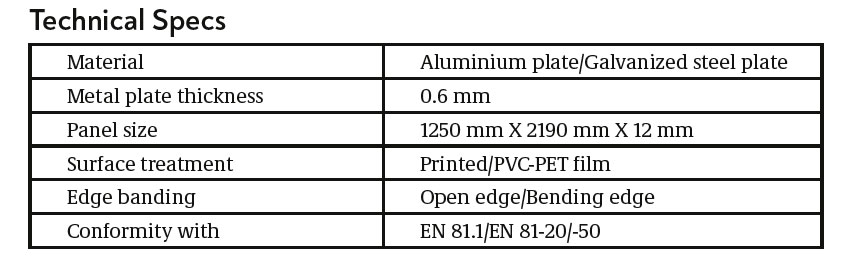

Polykastro, Greece-based DOPPLER, noting evolving market demands and client expectations, has released the EASE cabin series, which the company says was developed from its efforts to provide “new solutions with upgraded capabilities.” EASE is made of durable, lightweight materials designed to ensure high quality through such benefits as ease of installation and maintenance, durability and aesthetic choices. The EASE cabin uses double-sided aluminium honeycomb and galvanized steel-plate panels that are reversible, which can extend the cabin’s life in, for example, incidents of vandalism or wear from extensive usage. A wide variety of panels covers many aesthetic preferences, from classic tones to modern, bold colors. The client can also personalize the design by adding digital printing.

Installation is completed in a few steps. The number of requisite fixings is much lower than those needed for the typical cabin. Assembly of the walls is done from inside the cabin, saving installation labor time. Maintenance and reversing the panels are also done inside the cabin. EASE uses fireproof and waterproof materials in compliance with European regulations, which ensures a safe rider experience.

Elevator Monitoring Solution

Singapore-based ST Engineering is employing Henning’s technology to launch its non-intrusive AGIL Smart Lift Monitoring solution, which will be progressively installed on lifts in Singapore starting this year, a move ST Engineering says is “one of the largest-scale deployments of a smart lift monitoring solution to date.” AGIL Smart Lift Monitoring enables building owners, lift operators and technicians to have 24/7 remote status oversight and diagnostics, with centralised, real-time visibility of lift operations across different brands, models and locations.

The cloud-based AGIL Smart Lift Monitoring solution was co-developed with lift measurement device manufacturer Henning GmbH & Co. KG of Germany. The system uses Henning’s patented Donut rope load sensors, analysis algorithms and its WEARwatcher edge computing component, a car-top device designed around a 4×64-bit ARM controller that analyses lift data and sends only generated alerts to the cloud, which keeps communication costs low. ST Engineering, overseeing the rollout logistics, takes over the cloud back end, communication and system security. AGIL Smart Lift Monitoring provides a plug-and-play solution that eliminates the need to integrate with existing lift systems and allows installation in a flexible and scalable manner. The rope sensor technology allows for quick deployment and enables technicians to perform lift rope tensioning accurately and efficiently, thus optimising rope life.

How It Works

The smart sensors working with WEARwatcher take on data collection and sense-making at the secure and unified Internet of Things (IoT) platform. This generates real-time insights on lift performance and provides predictive analytics of individual lift components for maintenance planning that leads to reduced downtime and optimised component service life. These improve efficiency and reduce unnecessary costs and waste, allowing more sustainable lift maintenance. Integrated with a mobile application, the AGIL Smart Lift Monitoring solution provides real-time alerts and incident updates on the go, including remote diagnostics that identify possible causes and provide recommendations for more accurate and quicker diagnoses of lift issues. It’s part of a suite of smart city solutions comprising smart mobility, smart utilities and infrastructure, and urban environment solutions. With more than 700 smart city projects across 130 cities, ST Engineering helps its users transform into connected, resilient and sustainable spaces to enhance quality of life.

Get more of Elevator World. Sign up for our free e-newsletter.