Vertitron Midwest, Inc. (VMI) now offers vandal-resistant push buttons for car-operating panels and hall-call stations. The kits are available for existing locations for Schindler MPH, TAC 20 and 50 and Adams designer-style buttons. The push buttons are available in heavy-duty stainless steel with blue or red LEDs or custom color options, and are designed for heavy use and harsh handling. VMI also provides videos for installation assistance.

For more information, contact VMI at 19336 607th Avenue, Mankato, Minnesota 56001; toll free: (888) 864-3683; fax: (507) 245-4195; e-mail: [email protected]; or website: www.vertitron.com.

New Products From Cedes

The latest products from CEDES AG aim to increase elevator safety and efficiency. The GridScan safety light curtain ensures maximum safety for elevating platform users. Many elevating platforms do not feature cabin doors, and sidewalls are often open or consist only of rails. A danger exists for wheelchair users rolling backwards against the moving shaft wall or a gap between the cabin and shaft wall. Accidents are rare, even without a safety light curtain. Some platforms require passengers to press and continuously hold a button down for the platform to move; if they let go, the platform stops. However, this method does not completely eliminate risks.

The GridScan light curtain ensures the platform stops the instant a hand or foot gets too close to hazardous areas. GridScan is TÜV SÜD certified and fulfills Category 2 safety standards, according to EN 13849-1, making it ideal for safeguarding an elevating platform with open sides. It also fulfills Annex 1 of machine directive 98/37EC.

CEDES’ Triangulation Proximity Switch (TPS) 200 bed-detection system offers improved efficiency and passenger comfort for hospital elevators. Recognizing that patient beds leave little room for additional passengers, TPS 200 makes the cabin feel like a more private form of patient transportation. TPS 200 distinguishes between passengers and patient beds based on height differences. When a bed is detected, the elevator travels directly to its destination, bypassing other calls, saving time and avoiding unnecessary stops.

With three TPS 200 sensors installed in the elevator cabin ceiling

and an evaluation unit on the cabin’s roof, the sensors monitor the car interior. Each housing contains two independent sensor beams that are unaffected by light conditions and based on triangulation proximity technology, measuring the angle of the reflected light. This results in precise, reliable detection and is useful for background suppression. The application has seen successful field tests and is installed in several German hospitals in Manneheim, Duisburg and Schweinfurt.

For more information, contact CEDES at Science Park, CH-7302 Landquart, Switzerland; phone: (41) 81-307-2323; fax: (41) 81-307-2325; or website: www.cedes.com.

Stingl Scaffoldless Platforms

Stingl Systems GmbH now offers four types of scaffoldless platforms. The Stingl Mobil is a telescopic work platform made of glass-reinforced polyester (GRP). It can be used in various shaft depths and applications ranging from new installations to modernizations. It is equipped with a double platform with bracing parallel to the door/shaft opening, single-level platform without side protection and lateral side protection to the right of the shaft door opening.

The Mobil Pano is also a telescopic platform made of GRP and can be installed at any shaft door opening, regardless of story height. It is suitable for use on panoramic and glass lifts, and lifts with front and rear openings for shafts that do not allow for mounted systems. The Pano is particularly suitable for lifts without machine rooms where the machinery is located in the shaft head. It is equipped with an anchoring principle in front of the shaft door opening and features double lateral protection of the shaft door opening.

The Mobil Service is a mobile platform made of GRP that can be dowelled to the shaft wall or inserted into scaffolding sockets and is accessible from the roof of the lift car. Mobil Service is designed for new installations or retrofits. The Mobil, Mobil Pano and Mobil Service all have load capacities of 300 kg/m2.

The Mobil Car is a collapsible platform most suitable for maintenance and repair jobs in high shaft heads where the top cannot be used or charged with loads. It is designed with moderate dimensions, which allow it to be stowed on the car top. The Mobil Car is made of light metal and has a load capacity of 200 km/m2.

For more information, contact Stingl at Dimbacher Strasse 25, D-74182 Obersulm-Willsbach, Germany; phone: (49) 0-7134-3438; fax: (49) 0-7134-3437; e-mail: [email protected]; or website: www.stinglonline.de.

ECC Develops DL-20

ECC recently developed its DL-20, a microprocessor display device that integrates a high-resolution position indicator and video-display unit with an emergency phone and light unit. The DL-20 is equipped with a host controller adapter to help determine elevator problems remotely from any phone.

The DL-20 is Americans with Disabilities Act-compliant and allows for eight elevators to line share with an integrated line seizure, and master/slave phone control. In addition, an integrated controller host will screen for fault codes and display information onscreen for easy elevator troubleshooting. Users can call from any phone, and a voice chip will provide information about fault codes that have been activated. Additional features include: an LED emergency light with standard 6-V battery, USB slot for image downloads and a removable SD card for programming.

For more information, contact ECC at P.O. Box 57767, Sherman Oaks, California 91413; phone: (818) 753-5669; fax: (818) 753-9820; or website: www.eccelevator.com.

Vertíco Launches Focus Platform Lift

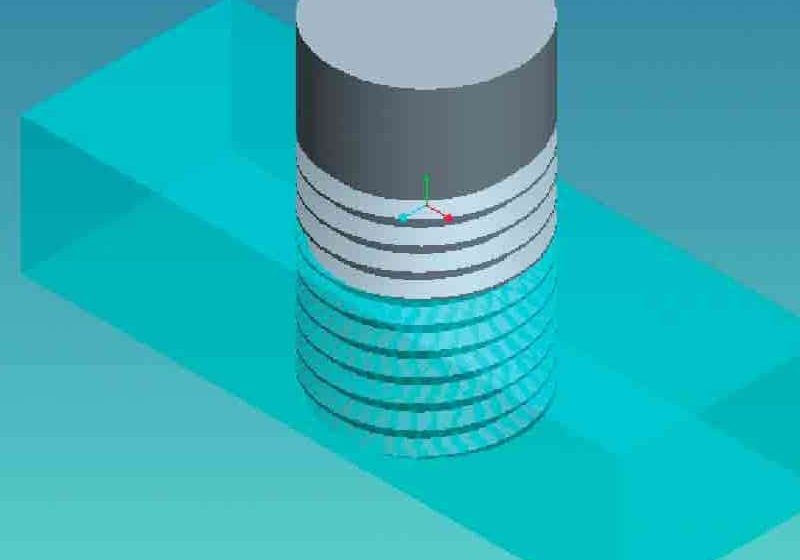

Vertíco Group has launched its Focus electric platform lift. The compact lift is designed with a self-sustaining screw-drive mechanism. The machine-room-less lift is pitless, requires minimal headroom space and has reduced assembly time. Vertíco offers three models of the Focus, with capacities ranging from 300-1000 kg. Additional features include a maximum speed of 0.15 mps, a light-curtain-guarded doorway, overload detection, an emergency light and emergency platform lowering.

For more information, contact Vertíco at 43058 Bogolese Sorbolo (PR), Italy; phone: (39) 0521-69-5311; fax: (39) 0521-69-5313; or website: www.verticogroup.it.

Foxfury Light, Spotlight Upgrades

FoxFury Lighting Solutions has upgraded its 4000-lm Nomad 4000 LED area spotlight, making it 400 lm brighter than its predecessor Nomad 3600. Cordless and rechargeable, the Nomad 4000 is a portable area light and spotlight designed to give users a quick-deployment lighting tool. The light’s design offers flood and focused light options, with built-in legs and a head that can telescope up to 8 ft. The Nomad 4000 can function as an 8° spotlight with the diffuser lens detached or as a 120° scene light with the lens attached. It can be deployed in 20 s with no warmup or cooldown time and employs the latest Cree LED technology.

Other features include:

- Conversion between an area light and spotlight in seconds

- Self-contained, rechargeable lithium-ion battery system

- AC or DC charge/drive

- Easy to transport, stow and deploy

- Silent and pollution-free operation

- Three light intensities

- 2.5-9 hr. of light per charge

For more information, contact FoxFury at 2091 Elevado Hills Drive, Vista, California 92084; phone: (760) 945-4231; fax: (760) 758-6283; or website: www.foxfury.com.

Smart Elevator Tech Deflector Sheave Isolator

Smart Elevator Tech, LLC has released its Deflector Sheave Isolator™, engineered to be a bolt-in-place set of isolation assemblies for elevator deflector sheaves. The company explains that the vibration and harmonics produced by even the finest elevator traction machine can be transmitted through the hoist ropes to the deflector sheave. If the deflector sheave is not isolated from the building structure, the machine vibration can be transmitted through the deflector sheave to the machine beams, perimeter building steel, and floor decks and walls of adjacent living space. In some cases, the natural frequencies of the structure can be aggravated by the machine frequency with a compounding effect known as resonance. Also known as “structural noise,” resonance can make floor decks reverberate like the skin of a drum as it emanates through the building structure.

Dealing with resonance includes properly isolating the original source of the vibration from the structure. Typically, elevator drive machines are isolated at their mounting, most commonly with neoprene pads or engineered isolators. Most deflector sheaves, however, are bolted directly to the underside of the machine beams and are not isolated from the building structure.

Each Deflector Sheave Isolator order is specifically engineered for the project based on the system weights (load), degree of deflection (in radians), center-of-sheave to pillow-block dimensions (offset), car-versus-counterweight deflecting (static or variable), etc. Vector-mechanics mathematics is employed to determine the tangential loading and orthogonal vertical and horizontal forces for the isolator assembly independently at each side of the sheave. The program compares the specific vertical and horizontal loading

for each mount with an array of engineered isolators designed for the low frequencies (Hz) of elevator machines. It then selects the ideal combination of isolators for use in each direction of the forces and for each side of the sheave.

For ease of installation, the Deflector Sheave Isolators are designed to bolt to the machine beams using the same holes as the original deflector sheave. This allows the isolators to be installed either with the elevator installation or as a retrofit. The assemblies typically require 6.75 in. of vertical space, lowering the deflector sheave by that amount. Each isolator assembly is labeled for the specific sheave side, and the set carries a unique serial number. To aid in replacement, drawings are provided identifying the isolators used. The design has been certified by a California licensed structural engineer, and job-specific structural certification is available.

For more information, contact Richard C. Blaska of Smart Elevator Tech at phone: (415) 819-5744, e-mail: [email protected] or www.smartelevatortech.com.

Get more of Elevator World. Sign up for our free e-newsletter.