Viva VT!

Jun 2, 2023

Otis provides bespoke vertical transportation (VT) for the first ground-up resort built on the Las Vegas Strip in more than a decade.

by Julie Brandt

photos courtesy of Otis

he site of the iconic Stardust Resort and Casino in Las Vegas has been reborn with the opening of Resorts World Las Vegas — one of the most luxurious resort properties ever developed in this Nevada tourist destination. Developed by Malaysia-based Genting Group, which owns a number of casino resorts around the world, the property features a 59-story tower with three separate Hilton hotels totaling 3,506 rooms.

Completed in 2021, Resorts World Las Vegas features 156 Otis elevators and escalators. The Asian-themed resort includes a 117,000-ft2 casino with 1,400 slot machines, nearly 120 table games, high-limit rooms, a poker room and a sportsbook. The signature structure is the glass-enclosed hotel tower featuring the Las Vegas Hilton at Resorts World, the Conrad Las Vegas at Resorts World and Crockfords Las Vegas. It is the largest Hilton-affiliated hotel property in the world.

Additionally, there are luxury suites, villas and penthouses with individual lobbies, open balconies and a sky casino. Other features include 250,000 ft2 of meeting and banquet space, a 5.5-acre elevated pool complex with seven pools and a spa. The resort has 100,000 ft2 of entertainment space, including The Theatre at Resorts World, a music venue with capacity for up to 5,000 people that’s scalable to host A-list performer residencies and corporate events, as well as a 50-ft diameter video globe to display more than 6,000 ft2 of LED content.

This property includes “The District,” a 70,000-ft2 retail center spread across two floors with more than 40 restaurants and bars, including an indoor food street known as “Famous Food Street Eats” with 16 food stalls. It’s expected that 75% of the resort’s revenue will come from non-gaming options such as live entertainment and restaurants. The property is decorated with thousands of trees, some 100 of which were salvaged from the Stardust.

While Resorts World is expected to employ approximately 6,000 people and help revitalize the northern Las Vegas Strip, it was a long time coming. The site’s original Stardust Resort and Casino was demolished in 2007, but new construction was halted the following year due to poor economic conditions. The property was sold to Genting Group in 2013, with construction beginning in late 2017 (the project repurposes some of the partially finished buildings, including hotel and parking garage structures). The COVID-19 pandemic slowed construction considerably, affecting the workforce, as well as presenting building material supply chain issues. As a result, an accelerated construction schedule was required and the innovative Otis SkyBuild® elevator product helped efficiently and effectively speed up worker and material delivery as the new buildings went up and the resort opened to great fanfare.

Otis has played a major role in the growth of Las Vegas since the resort and gambling destination first rose out of the Nevada desert to become the self-described “Entertainment Capital of the World.” As the city grew, Otis supplied equipment for some of the most distinguished casinos and hotels in town, including Venetian Palazzo, Mandalay Bay, Luxor, Paris, Planet Hollywood, Park MGM, Circa, Stratosphere, Aria, Vdara, Palms, Elara, Marriott Grand Chateau and several others.

Resorts World Las Vegas continues that tradition, with Otis supplying 156 units of industry-leading products including 42 SkyRise®, 77 Gen2®, six HydroFit™ and four HVS elevators, as well as 27 NCE escalators. Some of the elevators feature Otis’ Compass advanced destination-dispatching system. The company also installed a custom stage lift in the resort’s theater, an example of meeting a customer’s unique needs. Otis was also recently awarded a follow-on three-year service maintenance contract for all the resort’s elevators and escalators. Three of the SkyRise elevators began their life on-site as Otis SkyBuild units — the first time they were used in Otis’ U.S. Western Region — playing a critical role in efficiently and quickly moving workers and material skyward.

A primary driver for a hotel or casino developer is that deadlines dictate cash flow. Typically, such businesses advertise and book hotel rooms, conference space and entertainment tickets some six months before a scheduled opening — an opening that must be met. That means construction deadlines, even those that are accelerated, also must be met. As a result, more than 80 Otis field mechanics, including some from as far away as the Alaska branch, worked together on the installation around the clock (with as many as 30 mechanics on-site at any one time). The challenges were many: a condensed and “pulled in” schedule, the COVID environment and the need to incorporate previously completed construction, to name a few. Successful completion was due to a variety of actions — early estimating and scheduling and tremendous teamwork, not just within Otis but also incorporating the general contractor, developer and other trades.

The pandemic presented its own unique challenges. To reduce exposure, supervisors were extremely cognizant of who (and how many people) worked where on the site. The company supplied employees with masks featuring the Otis company logo to allow them to be recognized more easily. Otis had a safety manager on-site, not only to track COVID measures but to ensure safe work and hydration practices given the desert’s high heat and open building environment.

The site’s “start-stop-start” development presented additional challenges for the Otis team. When new work began on the resort there was already a partially completed, 10-story tower that had sat untouched and open to extreme elements for approximately 10 years. As a result, elevator hoistways and doorways had to be brought back to plumb before installation could proceed. In addition, new architectural design requirements had to be accommodated like expanding the size of some elevator door jambs.

One benefit of the previous construction was the parking garage and its 10 Otis Gen2 elevators that had been maintained by the company since installation a couple of years earlier. The garage proved to be valuable for the staging of equipment and material for the numerous contractors on site, as well as for parking. Going forward, the garage will be used for employee parking.

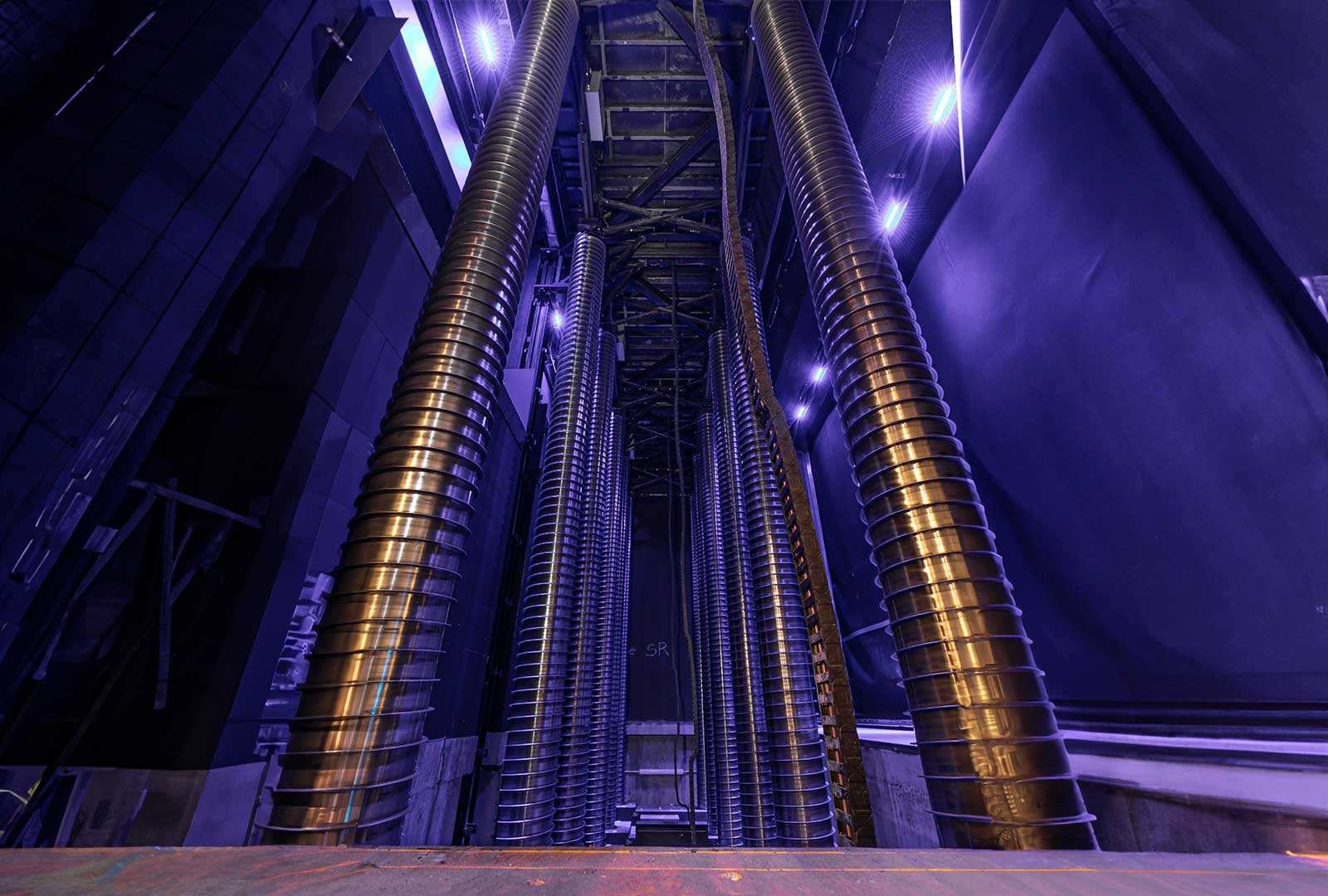

Much of the success in helping Otis and other trades on-site keep to tight deadlines was the use of three SkyBuild elevators that could quickly “jump” upward to be used for safe, indoor transport during construction and keep pace in pushing the building up without any additional heavy equipment. The self-climbing internal elevator transported workers quickly, comfortably and safely during construction, with crews spending less time waiting and more time on the job than with traditional external elevators. The SkyBuild system climbs in one-floor increments to keep pace with construction, and then quickly converts into a permanent SkyRise elevator upon the building’s completion.

SkyBuild elevators feature an angled deck that protects crews from overhead hazards; a working deck, used by Otis crews to install additional elevator rails; machine system platforms, central to the system’s unique design and supporting the SkyMotion® machine, controller, drive and travelling cable – components that become part of the permanent SkyRise elevator; a hydraulic platform representing the heart of the SkyRise system, with a hydraulic piston that moves the whole assembly upward in single-floor jumps; retractable support beams that hold the system in place and are retracted during the climbing operation; and a construction elevator cab that serves all floors below the SkyBuild assembly and, once construction is complete, converts into the permanent SkyRise cab.

As Otis’ premier high-speed, high-rise elevator system, SkyRise offers a unique combination of flexibility in design, superior passenger experience, industry-leading technologies, speed in construction, global organizational support and years of safe, reliable performance. It also allows many of the high-end custom touches befitting a high-end resort like Resorts World Las Vegas. Passenger cabs throughout feature custom door skins, as well as different cab interiors and finishes for the various hotels and casino spaces.

Each SkyRise installation integrates industry-leading technologies to ensure the seamless, safe operation of the entire system, with a sustainable design that minimizes space requirements and reduces energy use. Its features include permanent-magnet SkyMotion machines that are among the most energy-efficient on the planet; a compact, reliable and energy-efficient E2 intelligent control system that employs a patented motion-control algorithm to ensure a smooth ride; the ReGen® Drive, which adds energy efficiency; a noise-blocking Q-frame cab and aerodynamic shroud using computational fluid dynamics and wind tunnel tests to ensure a smooth, quiet ride; and safety brakes made from the same heat-resistant materials used for jet-engine nozzles.

Some people say you can’t complete construction on time, on budget and correctly all at the same time. Otis Elevator’s performance at the Resorts World project proves this adage is not true.

— Bill Richardson, principal of W.A. Richardson Builders

Each Otis elevator is a model of safety and reliability. The SkyRise elevator is no exception, with remote diagnostics that enable engineers to identify and resolve issues fast and an eService portal that provides instant access to real-time performance, maintenance and other critical information. The Otis Compass advanced destination management system often is featured in high-rise office buildings to swiftly and efficiently move employees and visitors to their final floor destination. At Resorts World Las Vegas, the dispatching system is featured on “back-of-the-house” employee service elevators to ensure staff get where they need to be as quickly as possible to provide the best customer service. Because the Compass system knows where people are going before they enter the elevator, it gets them there faster than conventional dispatching systems by using SmartGrouping™ technology that groups passengers according to destination floor, resulting in less waiting time, less crowding and fewer stops along the way. The system also acts as a virtual concierge to guide passengers to the appropriate elevators and spaces within a building.

For more than 20 years, the revolutionary Gen2 elevator has transformed the industry Otis created nearly 170 years ago. The Gen2 family of lifts blends convenience, style and performance to deliver superior passenger experience and is designed to maximize space savings and energy efficiency. Elevator features include high-performance door operators and superior car acceleration that allow passengers to enter and exit more quickly, a low-noise gearless machine that’s mounted on rubber isolation pads to reduce vibration and minimize noise in adjacent rooms and patented smooth polyurethane-coated steel belts that last twice as long as conventional steel ropes, without any lubrication.

HydroFit is a machine-room-less, holeless hydraulic elevator that saves valuable floor space along with construction time and costs. It is carefully designed to help coordinate busy trades by locating hall-call buttons in the door jamb. Perfectly adapted to work in fast-paced, smaller building projects, it cuts lead times and simplifies the planning process. Its energy-efficient attributes include LED lighting that reduces energy consumption and lasts 10 times longer than conventional fluorescent lamps and has a sleep mode that shuts down lights and fans when not in use, while seamlessly restarting with the press of a call button. Sleep mode makes LED lighting 75% more efficient than conventional systems.

While escalators are typically workhorse units in any commercial installation, that doesn’t mean the NCE escalators Otis provided to the Resorts World project couldn’t have their own custom touch — in this case, red handrails. The NCE is Otis’ series of escalators designed for commercial applications and is a flexible modular unit that can be assembled based on a customer’s specific needs. The NCE is designed to meet the extreme and varied demands of public spaces, raising the bar for endurance and reliability.

Otis escalators use rectangular steel trusses to increase their strength, with seal welds to protect them against internal corrosion. Escalator steps are subjected to dynamic load testing — 20 million times, which is 15 million more than normally required. All manufacturing facilities conduct step breakage tests as well, ensuring step quality and durability. And a computerized step-chain assembly jig is used for precise alignment of the tension carriage, track system and main drive. Otis’ smart lubrication system uses up to 98% less oil than manual lubrication systems, and sleep mode operation, plus LED lighting, further reduces energy consumption. Finally, a ReGen drive captures energy when the escalator travels in a downward direction, returning it to the power grid while consuming 60% less power than an escalator without a ReGen drive.

Despite the many challenges faced during construction, Resorts World Las Vegas is a shining example of Otis’ ability to climb a beginning-to-end journey to success. “Some people say you can’t complete construction on time, on budget and correctly all at the same time,” said Bill Richardson, principal of W.A. Richardson Builders. “Otis Elevator’s performance at the Resorts World project proves this adage is not true.”

Get more of Elevator World. Sign up for our free e-newsletter.