Machine room-less (MRL) elevators, which are widely used today, offer various ease of use. Space saving comes first since there is no need for a machine room. They are have widely at existing buildings, which are modernized and at facilities like residential buildings with limited shaft capacity.

Nevertheless, MRL elevators also have some difficulties of use and design.

In machine room-less elevators, motors are placed on a steel beam fixed in a well or on brackets attached to the rails. Space is saved when they are fixed to the rails. Specifically, round gearless motors save more space, as they can easily be mounted on rails. However, the vibrations of the motors fixed on rail brackets are transmitted to the rails and to the car as a result. Although manufacturers use isolating rubbers to absorb vibration, reducing them to zero is impossible. For this reason, their vibration values may be a bit higher than the elevators with machine rooms.

According to the requirements of the standard, dynamic tests should be arranged so that they can be carried out from outside of the well. Therefore, the required equipment and software should be added to the controller in order to carry out some tests for the verifications described in EN 81-20, Chapter 6. In order to carry out the tests, which are physically possible for the machine room elevators, the necessary equipment should be placed in order to prevent getting on the car.

Access to motor-encoder-driver group is more difficult at MRL elevators. When the car stops at lower floors in case of failure, physical access to this group can be impossible. Similarly, in order to gain access to the machine and the control elements inside the well, cabin should be taken to the required level. Although it may vary with different models, some manufacturers prefer to keep the control panel on the landing, while some manufacturers prefer to keep the mandatory control and test devices outside the well and install all other electrical components inside the well. In such installations, the difficulty at gaining access to the interior wiring may causes significant time loss.

In machine room-less elevators, isolation around the last stop well is very important. Contactors, which are used as on/off elements of the controller in residential buildings, may cause annoying noise at nights. Although STO driver is used in modern controllers, many manufacturers still prefer cheaper contactor elements. In the machine rooms of the machine room elevators, which are usually at the level of a mechanical floor or attic, the noise heard less outside the well.

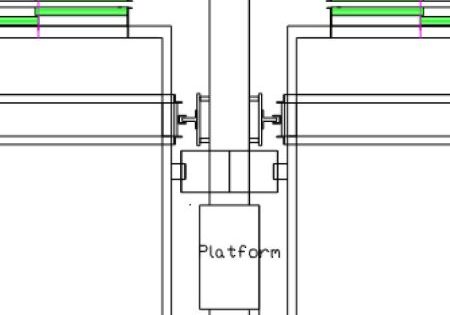

In case of maintenance or failure, which requires an operation with the engine brake or the engine, the standard obliges machine room-less elevators to have ways to evacuate maintenance personnel above the car. After the car is suspended and fixed on the rails, the maintenance personnel in the installations, where the car will stop due to a failure or brake problem, gets down the car through a trap door on the car and open the car door and gets out via the landing door by a clear opening of at least 70 x 50 cm above the car door header/door or via the car by access through an emergency trap door in the car roof, or gets out of the well through stairs or a platform outside the well. However, this evacuation scenario is not required for machine room elevators.

Control panels of machine room-less elevators are designed to occupy a smaller place. Therefore, the elements within the controller are relatively tight and it makes renovation and upgrade operations difficult. Additionally, control panels of the installations in hot regions operate at higher temperatures compared to machine room elevators. Cooling the machine rooms is easier than cooling the whole well. Temperature increase is a critical factor which shortens the life of electronic elements.

Travel, distance and speed of machine room-less elevators is limited. Although they reach 150 m and 3.5 m/s today, high-speed elevators with a speed of 4 m/s and above cannot be machine room less. In this case, the motor with an increasing volume and weight at higher speeds and capacities puts too much stress on the rails. Replacing the counterweight behind the car is also very difficult in machine room-less elevators. The motor should be placed transversely while such an installation is not preferred by many companies. Therefore, 1:1 roping is not common for machine room-less elevators. 1:1 roping, which is preferred in order to keep the motor speed low at higher speeds, cannot be applied in machine room-less elevators; therefore also are speeds are limited. Similarly, placing extra pulley group, which are required for high-capacity elevators (3-5 tons) with 4:1 roping, inside the well of machine room less elevators is very difficult. Therefore, machine room-less option is not preferred for huge elevators.

Machine room-less elevators became widespread since the beginning of 2002. While they initially had a speed of 1.6 m/s and 1.600 kg capacity, now they are installations with a capacity 3 tons and a speed of 3.5 m/s. Although their limits expand continuously, restrictive factors which affect design and installation limits should be taken into account when choosing this type of elevator.

Get more of Elevator World. Sign up for our free e-newsletter.