What Is a Diode?

Aug 1, 2014

The first diodes were the cat’s whiskers used to extract audio from a modulated radio frequency signal. Then there were diode vacuum tubes that performed the same function but were much more stable. Today, we are just about always talking about a silicon-based semiconductor device. These are very common in our electronic world and beyond, from simple children’s toys to the International Space Station. The diodes may be discrete electronic devices or numerous constituent parts of an integrated circuit (IC) or microchip.

First, by way of overview, we’ll see how diodes are used and discuss some of their electrical properties including how to test them and causes for failure. Then, we’ll take a look at how diodes work on a subatomic level. Of course, these small devices in sealed packages cannot be opened up and repaired, but it is very worthwhile to understand the inner workings since that provides insight into how diodes function in electronic circuits and also such understanding lays the groundwork for comprehending more intricate semiconductors such as transistors, MOSFET’s and IC’s.

Finally, we shall see the roles that diodes play within electrical equipment and discuss some of the troubleshooting techniques and failure modes that may be encountered in servicing motor drives, power supplies and control panels.

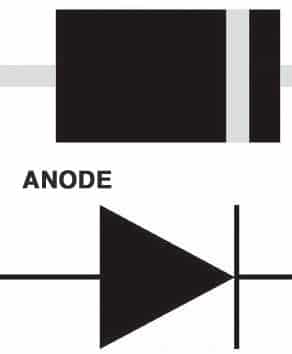

Most diodes are easily recognized. They are usually small tubular items with two leads, one at each end. The appearance is similar to a resistor, but instead of the multiple color-code bands, you will see printed on the package a small diode schematic, illustrating the current flow and in this way identifying the leads. Or there may be a single band denoting the cathode. Larger diodes, intended to handle high power levels, may have heat sinks with prominent cooling fins.

Electrically, the behavior of a diode is very simple. In a DC circuit, the diode conducts in one direction and does not conduct in the other direction. It resembles a check valve in a water system. But, when the check valve is subjected to back pressure, a diaphragm is pressed against a valve seat blocking water flow. The diode operates differently. As we shall see, reverse bias attracts the charge carriers away from the junction so that a submicroscopic layer with no charge carriers blocks the flow of electricity.

To test a diode, set your multimeter to the ohms function and touch the probes to the leads. Then, reverse the hookup. One way, the resistance will read high; the other way it will read low if the diode is good. For this test, the precise ohms values are not generally relevant. What we are looking for is a substantial difference between the two readings. If a diode fails, it usually becomes open or internally shorted — the event catastrophic. (This is in contrast to a capacitor, which may gradually lose capacitance.) What makes the ohmmeter test work is that the meter’s internal power supply, intended to facilitate resistance measurements, applies an approximate three-volt bias to the diode. When the positive probe is connected to the anode and the negative probe is connected to the cathode, the diode will conduct. When these connections are reversed, the diode will not conduct. Ordinarily, in performing this simple go, no-go test, you don’t have to be concerned about the polarity of the leads. Just ascertain whether there are widely different readings between the two hookups. For most purposes, that will reveal the status of the diode. For a complete understanding of what is going on, you have to realize that most meter manufacturers energize the probes so that red is positive. But since this is not always the case, you may want to check your meter using a known good diode and label the probes accordingly.

The ohmmeter test can be simulated using a small dry cell or DC power supply and milliammeter. However, it is always necessary to insert an LED, resistor or other load to limit current in the series circuit lest diode and milliammeter be instantly destroyed by heavy current.

If your multimeter incorporates a diode check function, make use of that rather than the ohmmeter function, as it measures voltage drop across the junction rather than resistance, which although adequate for most purposes is actually a pseudo-reading since the value is dependent upon the bias provided by the meter’s power supply. Using the diode test function, take two separate readings, one in each direction. Like the ohm function, the meter biases the diode. You can find the amount of bias by looking at the display when the probes are not connected to the diode and are not touching each other. When the diode is reverse biased, that amount will be displayed. If the value is less, there is reverse bias leakage, and if it is significant, the diode should be replaced. In the forward bias hookup, look for a 0.6 volt drop.

Of course, diode tests using the multimeter in either ohms or diode test mode must be performed with the equipment powered down. Some ohmmeters are protected against inadvertent connection to energized terminals, but, at best, the protection is not a sure thing. Many types of electrical equipment contain capacitors in close proximity (electrically) to the diodes. Caution is required, because the capacitors retain an electric charge long after they are powered down and disconnected from the power source. This is because the capacitors, especially electrolytics, are doing what they are supposed to do. Moreover, there is the phenomenon of distributed capacitance, which, as the name implies, is capable of appearing unexpectedly. Besides electric shock, arc-flash injury is possible. TV picture tubes and photovoltaic systems may be especially hazardous in this regard.

Many technicians shunt this electrical energy to ground by means of an insulated screwdriver or wire, but it is always possible to slip. Additionally, the high voltage spike can puncture the capacitor’s thin dielectric layer and destroy nearby diodes and other semiconductors. It is better to connect a power resister or other appropriate load across the source of stored energy and let it bleed off at a sensible rate. Use alligator clips with rubber sleeves and keep away from grounded surfaces. Do not work on this sort of equipment unless you understand the risks involved and know how to mitigate them. Don’t be fooled. Even a digital camera can harbor lethal voltages long after the battery has been removed.

Can a diode be tested in circuit or must it be removed? The answer is an emphatic “sometimes!” What you have to look at is whether there is a parallel current path that would disrupt the reading. That should be easy to determine visually or by consulting the schematic. If in doubt, temporarily disconnect one lead.

A diode’s internal subatomic mechanism is simple and easy to understand. Like other semiconductors, most diodes today are made of silicon, one of the most abundant elements on earth and the primary ingredient in quartz and common beach sand. It is an element with an atomic number of 14, and it is surrounded in the periodic table by boron, carbon, nitrogen, aluminum, phosphorus, gallium, germanium and arsenic, all of which share an important property that is key to this discussion. They have less than the maximum and more than the minimum number of electrons in the outer or valence orbit, which is where the action is in terms of interaction with the outside world.

Our solar system consists of planets and other bodies orbiting the sun. These orbits all lie in the same plane, whereas the electrons orbiting an atomic nucleus do not occupy the same plane but rush around at all possible inclinations. The orbits are best visualized as shells. Because silicon has four electrons in its outer (valence) shell, a single atom is capable of bonding tightly with four adjacent silicon atoms. Pure silicon organized in this way forms a crystal lattice of great stability, similar to diamond when the carbon atoms share valence electrons to form a crystal lattice. So configured, there are no free electrons, and for this reason the material is not conductive. But, when minute amounts of certain other substances are introduced, the situation changes dramatically. Specifically, if crystalline silicon is exposed to either phosphorus or arsenic, both of which have five electrons in their valence shells, the extra electron is not bound into the crystal lattice but instead wanders about in the empty space between the silicon atoms, greatly changing the crystal’s electrical properties. Now the silicon is more conductive. The process of exposing crystalline silicon to these impurities is called doping, and the resulting material is known as N-type silicon because the free electrons have a negative charge.

In contrast, when the crystalline silicon is brought into the presence of boron or gallium, both of which have only three valence electrons, there is a deficiency of free electrons. The resulting entities are not really positively charged particles like protons, but rather they are absences. They function like positively charged massless bodies moving through the comparatively vast spaces between silicon atoms. As a result, this P-type silicon also becomes conductive. The virtual particles in P-type silicon are known as holes. Both the electrons in N-type silicon and the holes in P-type silicon are charge carriers, and this is their reason for being; it is what makes semiconductors useful in our electronic world. On their own, N- and P-type silicon do not do much. Unlike pure crystalline silicon, these materials are conductive, but they are not like copper, which is highly conductive and malleable so that it may be drawn to form conductors.

To create a diode, small pieces of ultra-pure N- and P-type silicon are bonded together and wire leads are affixed to the far ends. The resulting devices are known as diodes, and together with more complex semiconductor devices such as transistors, they have changed our world.

Semiconductors are so named not because they are partially conductive like carbon or wire-wound resistors, but because under certain conditions they conduct and under certain other conditions they do not conduct. It has to do with how they are biased, i.e. which polarity is connected to which lead. The lead that is connected to the P-type material is known as the anode, and the lead that is connected to the N-type material is known as the cathode. As we all know, when it comes to electric charges, unlikes attract and likes repel. Visualize a DC power source attached to the diode, with a lamp in series. (If this experiment is performed using an ammeter, an appropriate load must also be inserted in series to limit the current, lest diode and ammeter be instantly destroyed.

If the positive pole is connected to the anode and the negative pole is connected to the cathode, the negative electrons in the N-type silicon and the positive holes in the P-type silicon will be repelled. These charge carriers will crowd from both sides toward the junction. The diode will conduct. The other scenario is that the negative pole of the power source is connected to the anode of the diode and the positive pole is connected to the cathode. Now the charge carriers are attracted to the poles of the power source. On both sides, they migrate away from the junction, which may now be considered a depletion area. Since there are no charge carriers in this region, the diode will not conduct.

The diode will conduct or not conduct depending upon how it is biased, that is depending upon the polarity of the applied voltage. A magnetic relay or vacuum tube can be configured to do the same thing, but the solid-state diode is less expensive, more reliable and, above all, faster acting, which is to say it is capable of much better frequency response.

Because of its ability to act as a one-way electrical valve, the diode has numerous applications:

- A blocking diode placed in series with a battery will prevent current flow if the battery is installed backwards into its holder, protecting valuable equipment from reverse polarity damage. Many DC generators function as motors when reverse polarity is applied. DC wind turbines have diodes inserted in series between the battery bank and the generator, so that the batteries will not discharge through the generator, spinning the turbine when there is no breeze. Solar PV systems are similarly protected.

- Zener diodes are used to regulate voltage. As we mentioned, diodes do not conduct when reverse biased. But if reverse bias voltage is increased above a certain level known as the breakdown voltage, the diode will suddenly conduct, destroying the device. Zener diodes are engineered so that they can tolerate this reverse bias breakdown voltage without damage, making them useful as voltage regulators, common in power supplies and seen in all sorts of electrical equipment.

- Avalanche diodes similarly protect circuits from high-voltage surges.

- Varactor diodes are used to electronically tune radio circuits.

- Tunnel diodes and Gunn diodes are used as oscillators in high-frequency applications.

- Light-emitting diodes have been used as indicator lamps in many types of electronic equipment, and recent advances in efficiency have made them suitable for high-performance flashlights, reliable exit lights in public buildings and even general purpose lighting. Handheld remotes for TVs, air-conditioners and similar equipment use LEDs to produce infrared beams. LEDs are also used in alphanumeric readouts.

Solar cells in PV systems are diodes. If any object is struck by radiant energy such as sunlight, the energy that is not reflected and not transmitted will be absorbed. This absorbed energy results in greater molecular motion but useful electrical energy cannot be extracted since the energy is random and the polarities cancel out. If the body happens to be a diode with a semiconducting junction, and if leads are affixed to the far ends away from the junction, a voltage will appear and if a load is connected, current will flow. To capture this energy, metal electrodes have to be fastened to the N- and P-type silicon. On the bottom side, this is no problem, but on the top side such a solid plate would block the incoming solar energy. A compromise is achieved by forming a grid so that electrical energy can be conveyed to the lead without entirely blocking the sunlight. The slender conductors that form the grid will have limited ampacity, so there is some loss in comparison to the bottom-side plate, but this electrode can be optimized by forming the grid members with a rectangular cross section, the long dimension perpendicular to the surface of the cell.

Since diodes conduct in one direction only, they can be used to rectify AC, the output being a pulsating DC, which can subsequently be filtered to smooth out the fluctuations. A simple rectifier can be built by putting a diode in series with an AC source. This is called a half-wave rectifier. As the name implies, only half of the wave is rectified, leaving blank periods in the output with an attendant loss of efficiency. A full-wave rectifier is more efficient, and the output is smoother so less filtering is needed.

Diodes can function as voltage multipliers, for example by doubling the input voltage. Various configurations can triple the voltage or, used in cascade, achieve very high voltage for experimental and other purposes.

Diodes are used for non-linear mixing of two voltages. This is known as amplitude modulation. A high-frequency carrier wave is modified by an audio or video signal. The high-frequency carrier is needed for transmission over distance. At the receiver end, demodulation occurs. Modulation and demodulation may be in the same enclosure, in which case it is known as a modem. Often the two operations take place hundreds or thousands of miles apart, but regardless of where there is modulation, there will be demodulation, and both operations require diodes.

Speed, direction of rotation and other operational parameters of an AC motor can be controlled by a variable frequency drive (VFD). This is a remarkable, user-friendly piece of equipment that depends for its operation on 12 or more large power diodes. When a VFD fails, a shorted or open diode is the usual culprit. A subsequent article will discuss VFD troubleshooting and repair in some detail. For now, we’ll make mention of the fact that for proper operation the DC bus should carry a pure direct current without harmonics or noise contamination. This is best ascertained by looking at the voltage displayed on an oscilloscope screen. All capacitors and diodes before and after the DC bus must be good. Do these tests with the power source disconnected and locked out, and with stored voltages fully discharged. Even with these protective measures in place, there is no need to touch any conductive parts. Use only fully insulated tools and test equipment rated for the system voltage.

Diodes are critical parts of every power supply in electronic equipment where it is necessary to convert AC utility or on-site generated power to DC. In seeking the cause of a malfunction, look at paths of heavy current flow; this usually means the power supplies or output stages and devices, such as speakers. If the system is dead, i.e. no response at all when connected to the power source, one or more diodes may be faulted. These, together with electrolytic capacitors, often go down. A frequent cause is a short circuit followed immediately by heavy current draw and then an open, after the fault burns clear. Also, line surges and transients can destroy diodes. Test them as described earlier and examine visually for damage.

Large power diodes have heat sinks to get rid of the excess thermal energy. Where the diode contacts the heat sink, a very thin layer of thermal grease should be applied, with no excess. The material fills in pits in the mating metal surfaces in order to improve heat transfer. It is similar to corrosion inhibitor that electricians apply at the terminations of large aluminum conductors in services. Never use standard multipurpose grease.

With so many sizes, shapes and electrical parameters, it is no surprise that diode part substitution may be problematic. That’s where the manufacturer’s data sheets enter the picture. These are available at no cost as PDF downloads. In your search engine, type in the parts number + datasheet. Fairchild Semiconductor provides complete, well-illustrated data sheets, and they are essential for design work and any repair where you may want to do parts substitution.

Some of the more important electrical and thermal parameters are:

- Maximum repetitive reverse voltage

- Average rectified forward current

- DC forward current

- Recurrent peak forward current

- Storage temperature range

- Operating junction temperature

- Power dissipation

- Thermal resistance, junction to ambient

- Breakdown voltage

- Forward voltage

- Reverse leakage

- Total capacitance

- Reverse recovery time

Additionally, there are performance graphs showing various electrical parameters with current plotted against voltage and a power-derating curve at various temperatures. Data sheets also show pictorial representations depicting the cathode identification band and parts number identification.

Get more of Elevator World. Sign up for our free e-newsletter.