Revision and renewal of the existing system, in order to provide efficiency for elevators and to meet the improving and changing needs, enables the existing units to be upgraded to a higher standard. Such a renewal adds value to the facilities with safety and energy efficiency that it provides, as well as unlimited solutions in terms of speed, capacity and travel distance.

What is Modernization?

It is a comprehensive operation that ensures elevators, which are no longer efficient, meet new standards and emerging needs throughout the life of the building. It is the fastest and the most economical way for meeting the current standards by using the mechanical infrastructure of the existing system.

Why is Modernization Needed?

- Operations that are carried out without risking safety of the workers in the facility helps them carry out their routine operations away from a building site atmosphere.

- If there is no construction work at elevator halls during modernization, then there is no additional cost for the facility.

- Almost all operations during the removal of old units and installation of new equipment takes place within the hoistway; there is no extra noise pollution in the building, and the daily routine is not interrupted.

- As stated in the Elevator Operation and Maintenance Directive, periodical controls of the elevators are carried out in accordance with the standards in effect at the construction time period of the elevator, if the speed, capacities and travel distances of the elevator are not changed during the modernization. Since modernization does not require new registry, the obligations required for the buildings by the new standards are needed. Thus, units are evaluated based on the standards that were valid on the first registration date and registered accordingly. Modernization is a preferrable option, as new standards cannot be met in old buildings.

- Modernization is carried out in order to meet the requirements for getting a green label. For Otis, the priority is to reach higher safety level with the existing units.

- Modernization adds value to facilities with different solutions while costs are kept at a lower level. Needs are evaluated in the most effective way following a detailed analysis of the existing unit. Based on the needs, new stops can be added, the number of existing stops can be reduced, or speed can be increased. After analyzing the components of the unit, equipment like motors, overspeed governors, buffers or parachute systems can be retained in order to provide faster solutions.

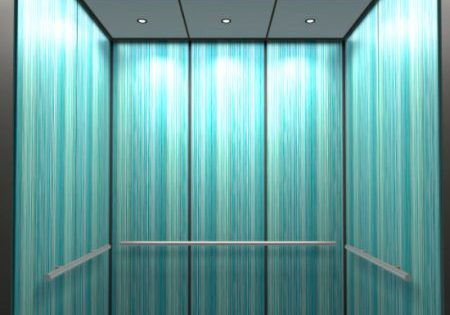

- Modernization provides unlimited solutions in terms of speed, capacity and travel distance. Design requirements can be met during modernization and with cabins that fit the architecture of the building, and a modern, spacious and technological environment can be provided.

- In order to provide maximum efficiency for the traffic within the facility, options that offer smart passenger guidance systems remote monitoring and specific planning opportunities, instead of conventional-call systems. Thus, the capacity of the facility can be increased to maximum efficiency and safety level.

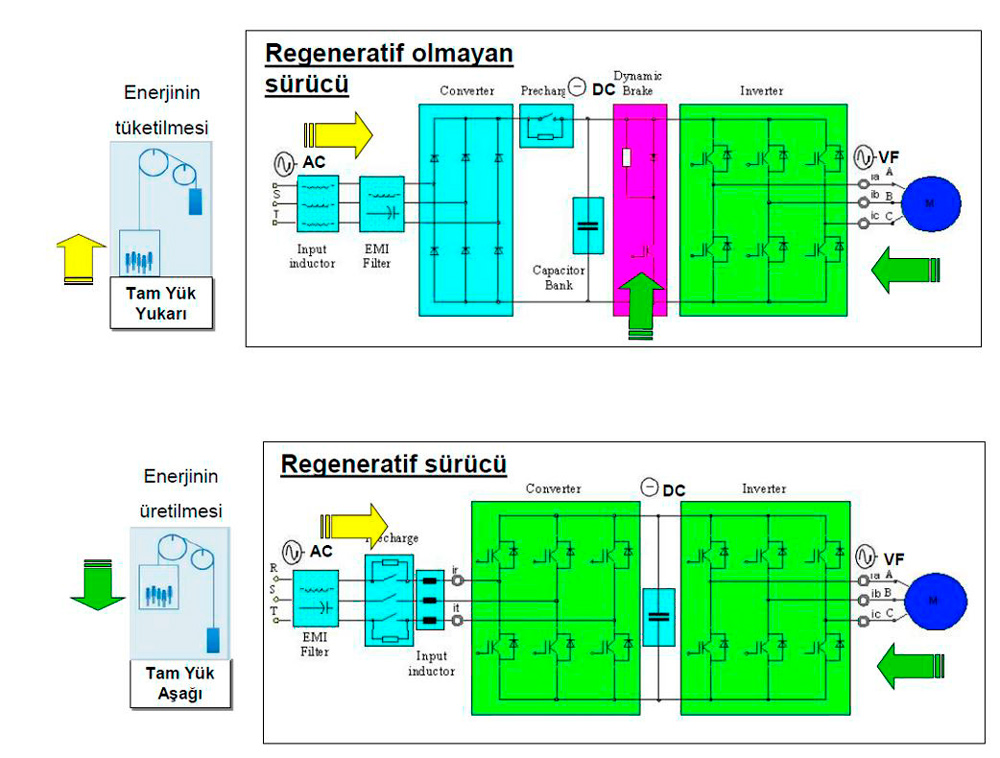

- Otis, which carries out modernization up to 8 m/s and travel distance of 250 m, provides maximum energy efficiency. Gen2 modernizations include the replacement of old, asynchronous motors and gearsets with new regenerative motors and permanent magnets. Conveyer ropes are replaced with polyurethane-coated conveyer belts. While offering the contribution of this replacement to travel comfort, it do not require lubrication compared to the old system, and is more environmentally friendly due to minimum energy consumption and constituted green building infrastructure.

Get more of Elevator World. Sign up for our free e-newsletter.