A continued discussion on the codification processes of wind turbine tower elevators in North America

At the 2008 American Wind Energy Association (AWEA) Health and Safety Workshop in Denver, OSHA requirements were often mentioned in the context of elevators. The reference was used to find a link between many varied standards and codes, yet one overlooked point was the actual reference in OSHA 1910.552 requiring elevators to comply with A17.1. Though this reference is dated, it remains. The OSHA reference to A17.2 for elevator inspections is further evidence of OSHA’s intent to ensure elevators are inspected following the guidelines and procedures of the elevator industry.

I believe the efforts being made by AWEA and the American Society of Mechanical Engineers (ASME) represent a strategic effort to create a new wind turbine tower elevator requirement in A17.1, and the cross pollination among chief inspectors in North America will lead to more AHJs recognizing wind turbine tower elevators. This should help dissipate confusion and create consistent enforcement, with both eventually becoming the norm.

Codification

At the start of 2009, a presentation on wind turbine tower elevators was given to the ASME A17 Standards Committee. The presentation detailed the conveyances and included the Iowa law and an effort by another standards writing committee (A120) to codify these devices. After the presentation, the A17 Standards Committee had a discussion and concluded that these devices were special purpose personnel elevators (SPPE) and should be under the scope of A17.

The Wind Turbine Tower Project team began working in March 2009, drafting a proposal to comply with the A17 standards committee ruling for a new requirement 5.11 to be developed. The first review and comment ballot closed in January 2011, the comments were responded to, and the project team issued the first consideration ballot in July 2011 and a second letter ballot in November 2011.

The development of the new code has proceeded with haste and caution. Fortunately, having A17.1 requirement 5.7 for SPPEs as a backbone to begin, the development of requirements for wind turbine tower elevators did not start from scratch. The project team started by determining the non-compliant and non-referenced elements of the elevators; once a list was developed, research, discussion and hazard assessment established the framework for the new requirements.

For organization, 5.11 follows the A17.1 Part 2 numbering scheme. For instance, where bumpers are located in 2.22, they would instead be located in 5.11.22. This was done to make cross referencing easier, as it is familiar to designers, manufacturers and inspectors. It also allowed further review of Part 2 requirements to be fully considered, ensuring current design, test, inspection and maintenance requirements are not overlooked.

Since the beginning of the project, the language is now in process of its third ballot. Balloting is a step in the consensus process for developing standards. The proposal is reviewed by the industry community, which can comment on the requirements and provide feedback to the developing committee. Once unanimity or substantial approval is obtained, the process is reviewed by American National Standards Institute (ANSI) before the requirements are published by ASME and the Canadian Standards Association (CSA) into A17.1.

The timing of the current balloting process is aligned to have the possibility of being published in the 2013 edition of A17.1, which is published every three years. It would be advantageous for it to be published in 2013 for the benefit of the industry, so there is consistency in design and inspection across North America. Once the ANSI review is complete, the unpublished standard can be used with assurance that the requirements will not change, and AHJs will be able to verify compliance consistently.

A17.7 Performance-Based Safety Code for Elevators and Escalators

The State of Iowa provided the option to use ASME A17.7/CSA B44.7 The Performance-Based Code for Elevator Safety, to obtain compliance in its law.[1] A17.1 is a prescriptive code that prescribes or specifies materials, surface finishes, factors of safety, etc. A17.7 is a performance-based code, which allows the designer freedom from specific materials, finishes or sizes with the provision that the new designs have an equivalency of the specific applicable parameters of the prescriptive code, the essential safety requirements are assessed in a risk assessment, a code compliance document reviewed by an Accredited Elevator Escalator Certifying Organization (AECO) and a certificate of conformity is issued. The system would then be equivalent to the prescriptive code, and, where an AHJ recognizes A17.7, the elevator can be permitted, installed, tested, inspected and approved to occupy.

For example, while specifying a particular size metal, which has a resistance to a force in the prescriptive code A17.1, it is possible to use many other materials besides metal to perform the same function, but the new material must perform equally well against the same force being applied to it as that required by the prescriptive code. It must also demonstrate the equivalent performance to the other risks, such as heat or corrosion, which are understood by using the specific term “metal.” In fact, the new material must be equivalent or superior in quality, strength, fire resistance, effectiveness, durability and safety to those generally prescribed by A17.1. Hence, A17.7 requires a thorough risk assessment to identify the hazards and demonstrate the equivalence to foreseeable risks with mitigations of those risks.

The basis for compliance to the performance code is that the equivalent prescriptive parameters in the prescriptive code be used.[2] Lastly, 17.7 requires a third-party certification body to evaluate the code conformance documentation and be satisfied that safety is achieved before the design is certified.

Current AHJ Status

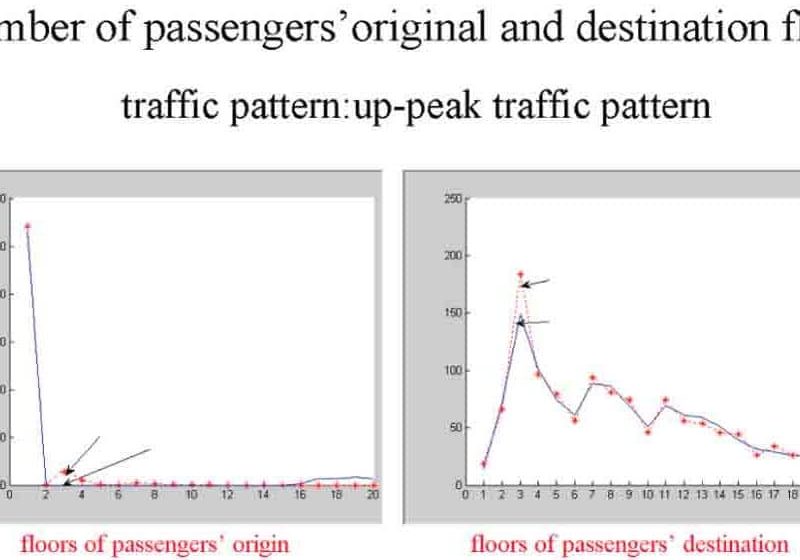

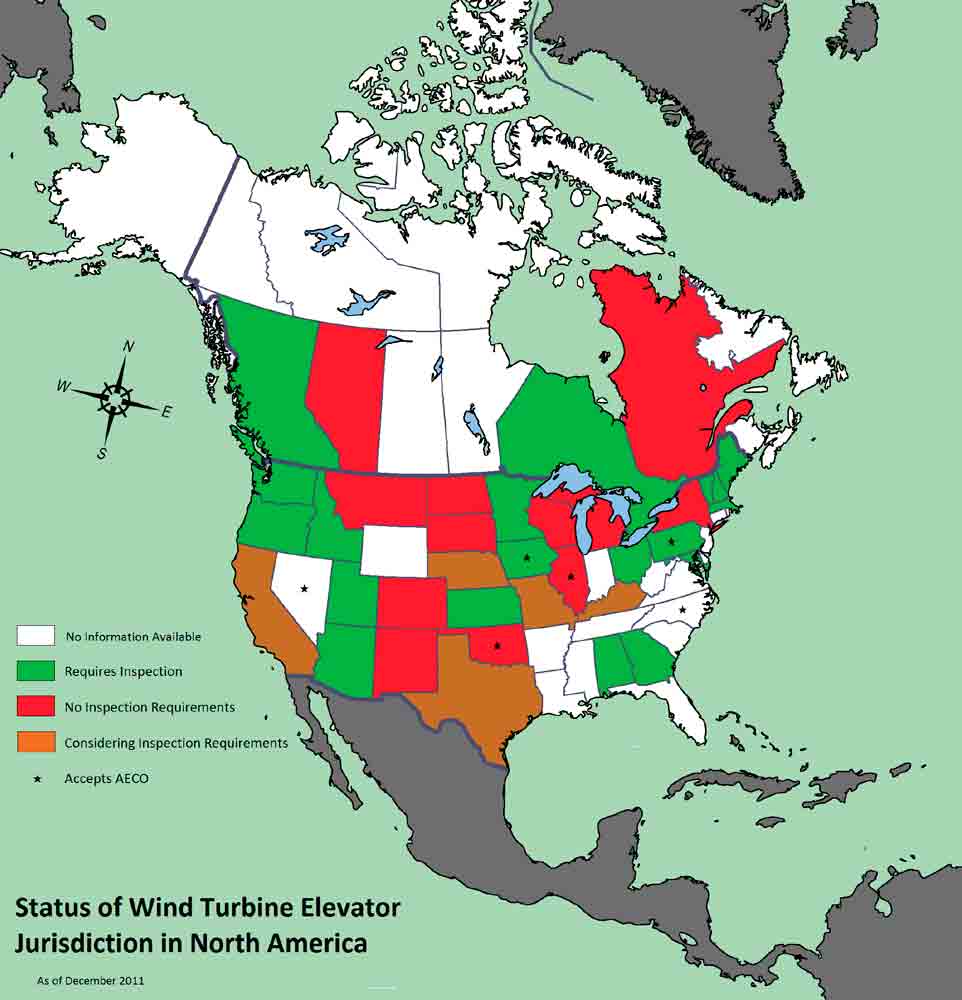

Since AHJs were notified of these conveyances, there has been an increase of jurisdictions requiring conformance to A17.1 or A17.7 as shown in Figure 1.

With the proliferation of wind towers throughout North America, these conveyances must comply with safety codes and design standards that will provide the highest assurance of safety for the life cycle of the device, even in jurisdictions that do not require conformance to A17. A primary driver for owners in North America is litigation. Legal risk can be one of the highest expenses of an elevator product because of the high-risk and high-value settlements that can be adjudicated. Not having a code or standard to design a conveyance to leaves the question of “What did you use to design it to if not the basic elevator code?” in the event of a failure.

There is ample evidence of the demand for safety when it comes to elevators. In conversations with fellow elevator consultants, SPPEs are not exempt from liability and litigation. Currently, there are cases involving fatalities where a design and maintenance failure will likely settle for very large amounts. Not following a known design code or standard increases manufacturers’ and owners’ liability and should be factored into the products being installed in North America.

Conclusion

This article is an attempt to clarify why the elevators in wind turbine towers are seemingly being regulated after they were installed. Elevator AHJs charged with elevator safety are simply enforcing the code as it applies to these conveyances and once all parties (elevator manufacturers, turbine manufacturers and owners) are fully apprised of the requirements, there is no doubt that the elevators will be designed to the new A17.1 code requirement 5.11, will require variances to A17.1, requirement 5.7, or be certified to A17.7/B44.7.

References

[1] Iowa Administrative Bulletin, published biweekly Volume XXX Number 26, June 18, 2008, pages 1,773-1,824, ARC 6852B Labor Services Division, adopted and filed emergency, pursuant to the authority of Iowa Code section 89A.3, the Elevator Safety Board hereby amends Chapter 71, “Administration,” Chapter 72, “New Installations,” Chapter 75, “Fees,” and Chapter 76, “Permits,” Iowa Administrative Code. 875—72.12(89A) Wind tower lifts. Wind tower lifts authorized by this rule shall not be installed in grain elevators, high-rise buildings, water towers, television towers or any facility other than a wind tower built for the production of electricity. This rule applies to all wind tower lifts, whether installed before or after May 28, 2008; however, this exception shall not apply to a wind tower lift if the contract for its installation is executed after an AECO is accredited.

[2] Canadian Standards Association and American Society of Mechanical Engineers, Perfor-mance-Based Safety Code for Elevators and Escalators. A17.7-2007/CSA B44.7-07. Ontario: CSA and ASME, 2007.

Also read: Wind Turbine Tower Elevators, Part I

Get more of Elevator World. Sign up for our free e-newsletter.