Draka and Gustav Wolf offer tech tips for proper installation and maintenance.

submitted by Draka Elevator Products graphics courtesy of Gustav Wolf

When installing, maintaining or modernizing an elevator, nothing is more important than doing the job right. And, perhaps more than any other component, hoist ropes are susceptible to problems merely by being improperly handled. It’s because of this susceptibility that Draka Elevator Products and Gustav Wolf have created these tech tips for the proper handling of wire ropes prior to and during installation, and for maintenance afterward.

Proper handling means:

- Transporting reels of rope on the jobsite by rolling them on a clean, flat surface or by lifting them using a pipe run through the reel center hole.

- Storing wire rope indoors, off the ground and covered to protect it from moisture, dirt, dust, sunlight and other elements.

- Taking care when unrolling rope from the reel. Do not pull the rope laterally when paying it off the reel, and avoid kinking and dragging ropes over sharp edges.

- Preventing ropes from rotating during installation, since free-hanging ropes will untwist under their own weight. The use of reeving splices is recommended.

- Seizing or securing loose rope ends with cable bands to prevent untwisting.

- Continually inspecting wire rope during installation to identify any areas that may have been damaged in shipment or while in storage on the jobsite.

Other aspects of rope installation and maintenance that should be considered or addressed follow.

Surface Line

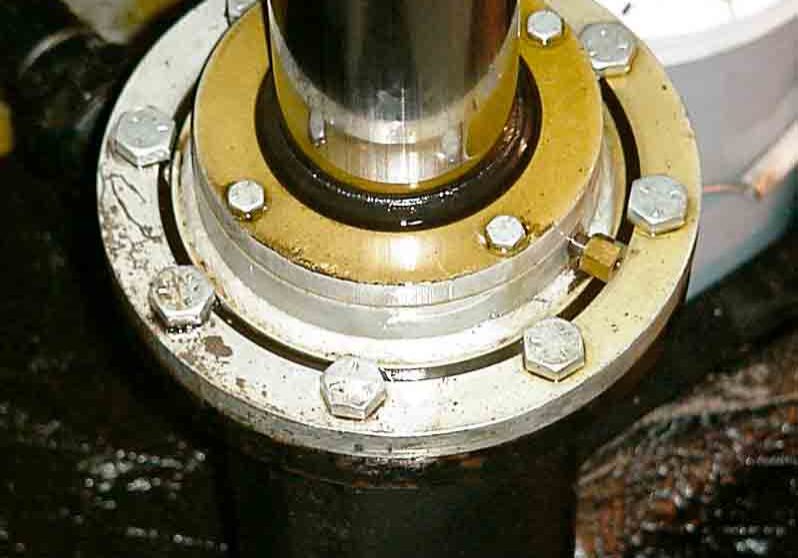

Some hoist ropes are marked with surface lines (Figure 1) that help installers visually determine whether the ropes have untwisted (which weakens the rope structure and reduces service life).

To use the surface line, make a full up or down run of the elevator after rope installation and count the number of rotations of the surface line. If the rotations per 100 ft. (30 m) of rope exceed the numbers below, the ropes should be adjusted by rotating the wedge sockets prior to tensioning, installing the retaining clips or tying off the hoist ropes:

- Wire ropes with 1:1 roping: one-and-a-half rotations per 100 ft.

- Wire ropes with 2:1 roping: three rotations per 100 ft.

Tensioning of Hoist Ropes

Equal tension must be maintained between individual ropes in a set. To avoid differential wear of sheave grooves and ropes and extend rope service life, installers should ensure that hoist ropes are equally tensioned at the time of installation, after four-six weeks, after six months and annually thereafter. Ropes are considered to be equally tensioned when the smallest tension measured is within 10% of the highest tension measured. Ropes with greater tension/load will press harder into the sheave grooves, resulting in increased overall rope wear; ropes with lesser tension/load will slide through the sheave grooves, causing increased crown and sheave wear.

The use of “tuning/plucking” or using a torque wrench to determine tensioning is not recommended. Today, elevator installers have access to highly accurate electronic rope-tension-measuring devices that allow the quick and accurate checking and adjustment of tension.

Field Lubrication Policy

It is strongly recommended that annual lubrication be done every spring, if the ropes become dry to the touch, or after every 250,000 starts, whichever occurs first. Note, however, that governor ropes should NEVER be relubricated.

Wire rope may be paid off a reel supported by jack stands with a helper using a board as a brake (Figure 2) or by paying it off a coil as the helper rotates it (Figure 3).

When paying rope off a reel or coil, do not pay it off the top or pull it laterally, as this can lead to kinking (Figure 4).

- Figure 1

- Figure-2

- Figure-3

- Figure-4

Get more of Elevator World. Sign up for our free e-newsletter.