Yitzchak Navon Train Station

Mar 1, 2021

Complex train station design challenges installers, who devise a custom monorail system to move escalator sections.

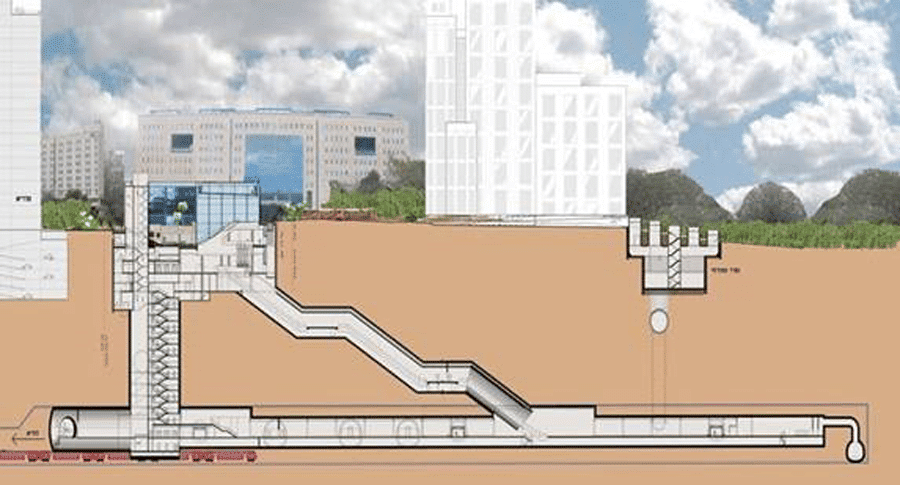

We care a lot about height in the vertical-transportation industry. Getting passengers to the top of the world’s tallest skyscrapers is a feat akin to climbing the tallest mountains. However, in the world of public-infrastructure escalators, it’s not height, but depth, that gets the glory. Turn a mountain upside-down, and you get something similar to the Yitzchak Navon Train Station in Jerusalem, where Otis escalators and elevators seamlessly transport passengers from the “top” (street level) to the “bottom” (train platform) some 80 m below.

Yitzchak Navon Train Station

Also known as the Ha’Uma Station, the station serves the A1 high-speed train line from Jerusalem to Tel Aviv. Officially named after Jerusalem native Yitzhak Navon, the fifth president of Israel, it’s located near the Binyanei Ha’Uma International Convention Center and constitutes part of a major public transportation hub, situated adjacent to the Jerusalem Central Bus Station and a station serving the Jerusalem Light Rail.

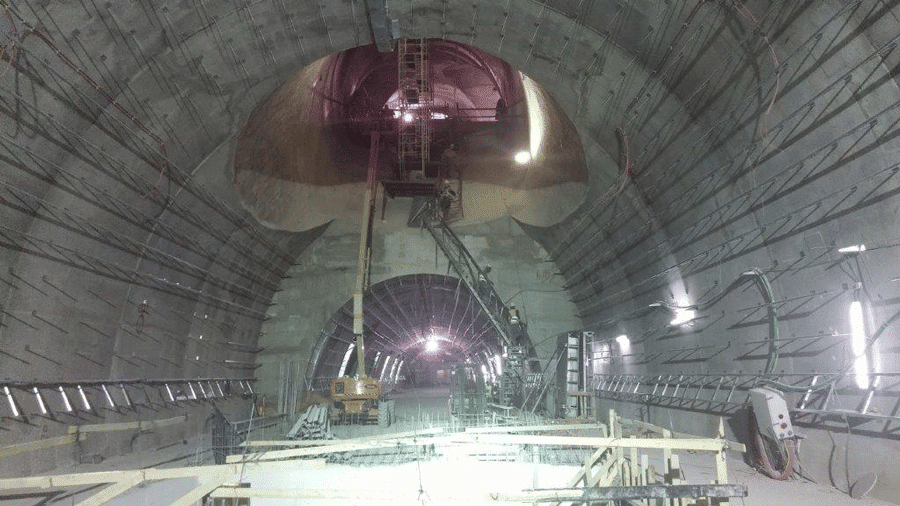

The facility is the world’s deepest heavy-rail passenger station and fourth-deepest underground station, featuring a tunnel approximately 1 mi long. Its entrance is located at an elevation of 815 m, with most of the station’s 60,000 m2 of floorspace underground. The descent to the passenger platforms is accomplished using either a vertical shaft in an oval cut, which includes six elevators, emergency stairs and ventilation shafts, or a 12-unit system consisting of three sets of four escalators, each section of which is 45 m long. The facility’s lower level includes the station, platforms with escalators and technical structure, including ventilation blowers, generators, cooling units and electrical rooms. Due to the depth of the station, vast amounts of air must be pumped in from street level, and a system for air emission and smoke release in emergencies is required.

Otis provided 25 of its heaviest high-rise escalators (13 515 NPE-model escalators and 12 520 NPE units), 12 elevators (nine Gen2 elevators, including eight Gen2 Premier and one Gen2 Comfort) and three locally designed elevators based on Otis components. This was through Electra Elevators, which has been Otis’ exclusive distributor in Israel since 1967.

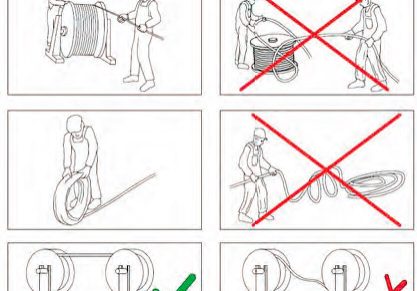

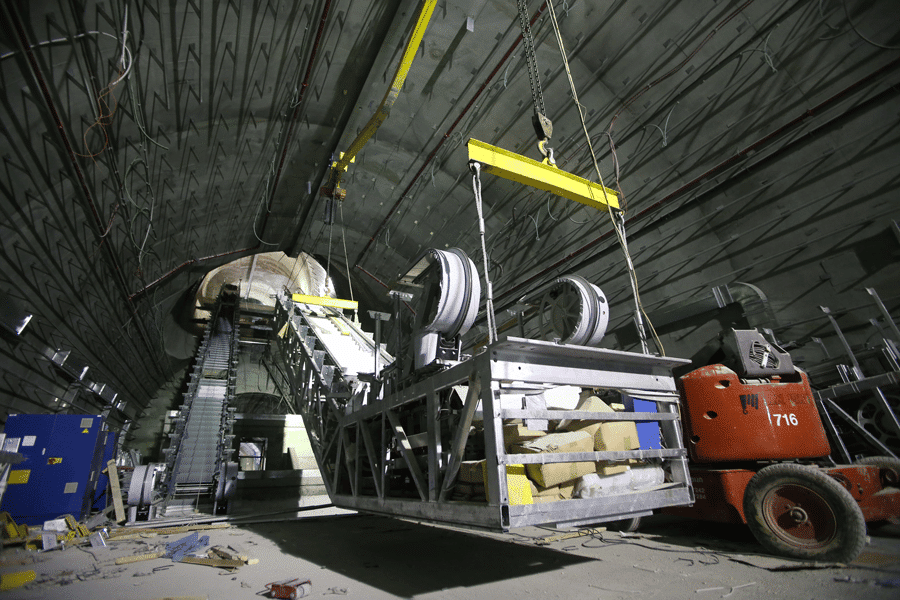

The primary project challenge came in solving how to move the 12 520 NPE escalators into the site for installation, then lifting and positioning them into place. Each escalator weighs approximately 32 T. and was divided into six segments prior to installation. The creative engineering and logistical solution involved utilizing a custom monorail system anchored to the tunnel ceiling through which installation teams could transport each escalator segment through the hoistway.

While the elevators provided are impressive in and of themselves — some featuring glass doors and panoramic views — it’s the story of how the escalators were installed that stands out. Shoham Saporta, vice president of engineering for Electra Elevators, summarized:

“Israeli Railways is one of our biggest customers. . . . We used the monorail system, fitted with a large and heavy drum winch, to lift, place and install each escalator and worked around the clock to get it accomplished. As a result, we were able to install the 12 units in just one-and-a-half months.”

The heavy-duty escalators serve as the primary means of moving train passengers to and from the platform far below. They are at an inclination of 30° and in three groups of four escalators each. In total, they travel approximately 1 km. To meet the demands of heavy use, they have a rectangular tube truss and sealed welds, which both protect from corrosion and

Credits

Owner: Israel Railways

General contractor: Electra Ltd.

Architect: Barchana Architects & Town Planners

Project consultant engineer: ESL – Eng. S. Lustig Consulting Engineers Ltd.

Services provider, equipment manufacturer and component supplier: Otis (through Electra Elevators, Otis’ exclusive representative in Israel)

Get more of Elevator World. Sign up for our free e-newsletter.