Hyundai Elevator Focusing on Modular Technology in Korea

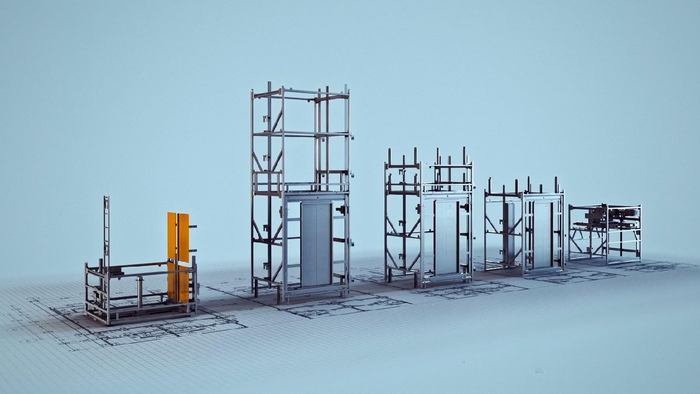

Hyundai Elevator achieved the first domestic commercialization of modular elevator technology in Korea, Pulse is among outlets to report. Demand for modular elevators is expected to rise as they reduce workplace hazards and shorten construction times. According to industry sources, Hyundai Elevator completed development of its modular elevator technology and is in discussions with a major Korean construction firm for on-site supply. Modular elevators are assembled in advance at the factory and then installed as completed modules into elevator shafts at construction sites, which minimizes high-risk shaft work, reducing accident risks and cutting installation time by 60 to 70%. The method also improves quality consistency, as elevators are produced in controlled environments. Labor needs at sites are reduced by around 30%, easing chronic workforce shortages and lowering construction costs. With the South Korean government’s recent housing supply plan also calling for greater use of modular housing, adoption of modular elevators is expected to accelerate. Hyundai Elevator has been investing in modular systems for years as a future growth engine, conducting both R&D and prototype testing. According to market estimates, the global modular elevator market is projected to grow from US$1.85 billion in 2024 to US$3.47 billion by 2033 at a compound annual growth rate of 7.2%.

Get more of Elevator World. Sign up for our free e-newsletter.