1WTC: There and Back Again!

Dec 1, 2014

Memories are recalled as work on the 1WTC vertical-transportation system wraps up.

photos by Robert S. Caporale and ThyssenKrupp Elevator

In the fall of 1964, with a year of college under my belt and about 20 extra pounds of my dear Mom’s fine Italian cooking, I had a burning desire to marry the love of my life. To achieve this, I left school to seek a job as a draftsman. After three interviews, I hit gold when I landed a full-time job at Jaros Baum & Bolles Consulting Engineers (JB&B), which was then and still is one of the world’s premier building-services engineering firms.

I was interviewed for that job in New York City (NYC) and ultimately hired by Calvin L. Kort, who was then not only the head of the JB&B Elevator Department, but also the JB&B partner who did all of the interviewing and hiring of prospective engineers and draftsmen. After agreeing to a start date of October 16, I was told that I would soon be joining the JB&B team that would be designing what, at the time, was to be the world’s largest construction project, which would also include the world’s tallest buildings. This was a remarkable way for me to begin what would ultimately be a 50-year elevator-industry career and the start of what was to become a truly remarkable professional journey.

Fast forwarding to August 25 of this year, my World Trade Center (WTC) experience was further embellished by a visit to the nearly completed 1WTC building with two of my closest friends and JB&B colleagues, Ronnie Carter and Awni Haddad, who were instrumental in developing and designing the building’s vertical-transportation systems.

My day began as I entered the reception room of JB&B to keep an appointment I had made with the firm’s Managing Partner Emeritus Augustine Digiacomo, the firm’s partner in charge of the new WTC project. Digiacomo and elevator consultant Steve Kinnaman developed the 1WTC elevator scheme, and Haddad and Carter did the lion’s share of the JB&B elevator and escalator work, developing the contract drawings and specifications, reviewing and approving the shop drawings, and commissioning the vertical-transportation systems for 1WTC.

After a bit of reminiscing with my old JB&B friends and an update on the status of the entire WTC reconstruction project, we went to the WTC site and met up with ThyssenKrupp Elevator Regional Project Manager Matt Chorney and Public Relations Specialist Jane Scott. Chorney led our tour, during which we rode the elevators, peered into the elevator hoistways and pits, and spent time examining and marveling at the machines and control equipment in various elevator machine rooms.

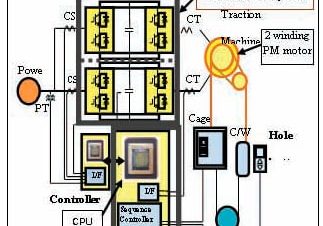

Massive hoist machines drive the five J-bank elevators from the lowest levels of the building to the observation deck and restaurant located at floors 101 and 102 of 1WTC. These elevators, with a rated capacity of 4000 lb. and speed of 2,000 fpm, are among the fastest in the world. Their exceptional ride quality is due to many innovative features ThyssenKrupp Elevator developed and innovative techniques it used to design and install the equipment.

To maintain the high-quality ride characteristics of the observation elevators, each car was provided with aerodynamic shrouding above and below, and a specially designed onboard, computerized active roller guide system. These elevators were installed with very substantial and precisely plumbed rails, and the active roller guide system makes any additional minor adjustments to position of each roller guide when necessary to further enhance an elevator passenger’s riding experience.

Car ride quality was exceptional on all of the elevators in the building, and although we didn’t have any quarters on hand to see if the elevators could pass the “quarter on edge balance test” of years past, it was quite evident to all of us on this visit that the 1WTC elevators would have passed such a challenge with flying colors.

The ThyssenKrupp Elevator team often worked around the clock to finish the elevator installation on schedule, though their efforts were often interrupted by numerous visitors from around the world who, while they were in NYC, felt they just had to see what they could of this world-renowned construction site and its monumental elevator installation.

In its final configuration, the 1WTC vertical-transportation system consists of 71 elevators and 11 escalators serving a building of 102 occupied floors that is 1,776 feet in height. It is the tallest office building in NYC and second to none in its use of innovative vertical transportation and life-safety systems. The accompanying riser diagram drawn by and provided to ELEVATOR WORLD by Haddad describes the entire vertical-transportation system.

As can also be seen in the accompanying photos, the view from the observation level of 1WTC is spectacular. The next time you are in NYC, be sure to check to see if this area of the building is open to the public. If it is, be sure to visit this remarkable location at the top of one of the world’s most famous cities. A trip up to it will also enable you to experience another remarkable elevator riding experience, the nature of which I will keep in abeyance at this time. It is certain to be a trip you will never forget. Being involved in the WTC project throughout the last 50 years of my life has been a wonderful experience. This most recent visit to 1WTC with my good friends at JB&B has truly been, as J.R.R. Tolkien subtitled his most famous novel, a trip “There and Back Again”!

Get more of Elevator World. Sign up for our free e-newsletter.