A “Marriage” Made in Heaven: Steve Grainer and Mitsubishi Electric US

May 1, 2021

Upon his retirement, Grainer (SG) took time to speak with your author (KW) about his long and illustrious career.

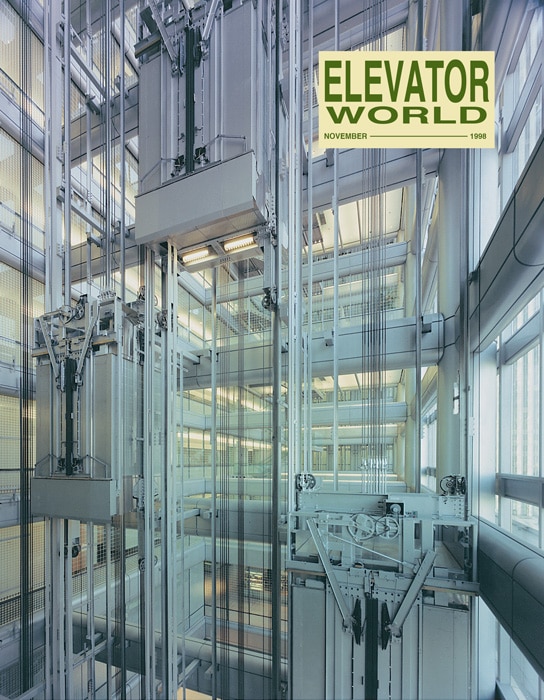

Founding father of Mitsubishi Electric US, Elevator & Escalator Division, is just one of the nicknames by which Steve Grainer is known. That is no wonder, since, as its first employee, he was instrumental in shepherding the division to becoming the powerhouse it is today. Grainer’s influence is still apparent. Division Chief Operating Officer Mike Corbo, whom Grainer hired as a salesman back in 1986, said he would not be where he is today without Grainer. “It was his passion and conviction that convinced me to join the team, and it was his passion that lives on within our company,” Corbo observed. The iconic projects on which Grainer has worked include the division’s first installation at Hotel Nikko in San Francisco and, later, Emerald Plaza in San Diego. In November 1998, the elevator installation at Blue Cross/Blue Shield headquarters in downtown Chicago made the cover of ELEVATOR WORLD.

Before coming to Mitsubishi Electric US, Grainer worked in the engineering departments at US Elevator Corp. and architecture firm Skidmore, Owings & Merrill (SOM), joining Mitsubishi Electric US in 1986. He was named vice president of engineering and service seven years later (EW, November 1993). Grainer is a man of character and his word, said Mitsubishi Electric US spokeswoman Margie Harvey, and one of the most respected members of the elevator industry. He is a skilled engineer with a deep knowledge of codes. He is “always about the people,” she said.

That is evident in talking to a few of his colleagues. Mitsubishi Electric US Modernization Manager Scott Miller said when Grainer arrived, he quickly adapted to the company’s needs, successfully tackling business development, sales and project management. Miller said:

“[Grainer] has always been a deep thinker, and I believe he strived to keep his philosophy of life in harmony with the way he conducted himself at work. He has a passion for quality and doing things right and is always respectful of everyone. That way of thinking fits very well with the Mitsubishi Electric philosophy, and, in various ways, I’m sure [Grainer’s] character helped shape the culture of our U.S. operations.”

Grainer’s influence and impact extended far beyond U.S. borders. Mitsubishi Electric former Vice President of Engineering Koichi Mita said in Grainer’s role as engineer, he was crucial in securing a major contract with the Thailand Mass Rapid Transit (MRT) Authority for an MRT project in Bangkok in the late 1990s. Mita recalled:

“[Grainer] was dispatched from [U.S. headquarters in] Cypress, California, to Bangkok to participate in the project. At that time, I worked at the engineering center in Singapore and traveled to Bangkok every week. The customer [Thailand government] hired a British elevator and escalator consultant, and consultant requirements were always tough. [Grainer] took the lead for our team and prepared all the technical documents. He sometimes worked until midnight. He was also our main presenter with the British consultant, and, thanks to his support, we secured the contract.”

He is retiring this year, after half a century in the elevator industry, including 35 years with Mitsubishi Electric US.

KW: Tell me about your early years and your family.

SG: I was born in Middletown, Ohio, in 1947. I was fortunate to attend a private grade school for my basic education and completed my studies at Stephen T. Badin High School in Hamilton, Ohio. After I completed my time in the Army (1969-1972), I traveled across America a couple of times. I met my wife, Domenica, in 1971 and have been married for more than 51 years. We have two beautiful daughters, two wonderful sons-in-law and five amazing grandchildren.

KW: How did you become a part of the elevator industry?

SG: My wife and I moved to San Diego with the idea of my working in the aircraft industry on the supersonic transport (SST) program. In 1986, Congress failed to pass a bill that would have supported SST. Many engineers were thrown out of work along the coast, all the way up to Washington. I was lucky enough to find not only a job in elevators, but also a career. I accepted a position as an engineer with US Elevator and attended Grossmont College in El Cajon, California, at night. I stayed in engineering for 10 years. Because of my code skills, I was charged with all shop and field liaisons. This provided wonderful hands-on knowledge that lasted throughout my career.

KW: Tell me about your first job in the industry.

SG: In 1971, US Elevator had an engineering staff of about 12 people serving many branch offices around the country. The four owners had a manufacturing philosophy of cost reduction by making components such as governors, counterweight frames, machine bases and other parts of sheetmetal, rather than castings or structural steel. The company was best known for introducing the first microprocessor elevator controller. The company was young, founded about a year before my employment (1970). Many manufacturing methods used by US Elevator are commonplace and used in the market today. The opportunity at US Elevator was a wonderful training ground for me. The company had a cohesive working atmosphere that was really revolutionary for its time.

The Blue Cross/Blue Shield headquarters in downtown Chicago graced a 1998 EW cover.

KW: How did your early jobs in the industry prepare you for the rest of your career?

SG: My introduction to codes — not just elevator codes, but all codes that regulate our industry — was the single most important factor in my career growth.

KW: Were there any mentors along the way?

SG: There are far too many to name. Steve Edgett of Edgett-Williams Consulting Group has always been an exceptional mentor.

Mentors should either know the correct answer, tell you they are not sure of the correct answer or refer you to another authority and/or have you go find the answer on your own and report back to him or her.

My introduction to codes — not just elevator codes, but all codes that regulate our industry — was the single most important factor in my career growth.

KW: Tell us about your history with Mitsubishi Electric US. What was your first position at the company? How did your place within the company evolve?

SG: Masaharu Hattori, the first president of Mitsubishi Electric, hired me as assistant manager of engineering, reporting to Hirokoji Ayabe. When I joined Mitsubishi Electric, we were installing three projects. The contracts were all executed in Japan by Japanese contractors. We did not yet have any American salespeople. Mitsubishi Electric was trying to figure out how to sell high-end office and hotel elevators with the world’s highest quality and most robust equipment to educated American owners and general contractors.

The challenges involved in this included talking about how the elevator ride was so smooth that you could stand a nickel on its side and go from the first landing to the uppermost landing without the nickel falling over. We would talk about our callback rate, which was less than one per elevator per year. Companies in the U.S. market were satisfied to achieve seven callbacks per elevator per year. We had a challenge in proving this unique value proposition. The problem was, we had no installations completed in the U.S. that could verify these bold quality claims.

I quickly realized that Mitsubishi Electric needed me more in a sales capacity than in an engineering position. I was an honest person with a good work ethic and a rich history of working in application engineering, consulting, sales, contract administration and shop and field problem resolution. I knew how to fit all types of elevators into class-A buildings, provide traffic studies, establish quantity and speed of required elevators, write tender specifications, prepare project schedules and produce bids.

I also learned the codes that regulated our industry and, finally, established contacts across my career with inspection authorities, consultants and — most importantly — trusted contacts with class-A building owners and general contractors. It would be accurate to describe the relationship between myself and Mitsubishi Electric US as a “marriage made in heaven.”

KW: Of which projects are you proudest of having been a part of during your career with Mitsubishi Electric US?

SG: Selling the first project in any area is always going to be the one that feels best, because it requires the use of all your skills. Among them are Blue Cross/Blue Shield and South Coast Plaza in Costa Mesa, California. South Coast Plaza included glass elevators and was particularly epic and rewarding.

KW: Tell us a little about the skills you found essential to your success in the industry.

SG: Problem resolution was as natural to me as the skin covering my body. Certainly, the design and engineering I learned at Mitsubishi Electric US, the sales aptitude I gained everywhere, my growth at SOM and the contacts I was able to establish were more valuable to me than gold.

KW: You are referred to as the founding father of the Mitsubishi Electric US team. What does that mean to you?

SG: As a founding member, the most important word in the equation is “team.” We were able to create that team atmosphere back in 1986. That is, in 1986 when we first formed Mitsubishi Electric US, we were able create a team — a team that still exists today. I believe that Mitsubishi Electric’s social consciousness and desire to create the best is the foundation that sets us apart.

KW: What advice would you give young people entering the industry today?

SG: In my lifetime, I’ve found few substitutes for experience.

The Lord’s Prayer asks us to forgive others. In the elevator industry, it is critical.

KW: What are some of your retirement plans?

“Problem resolution was as natural to me as the skin covering my body.”

SG: I first experienced gardening through my grandmother. I have a desire to make her proud. I have wonderful family in Upland, California, and Toronto, Canada. I look forward to traveling again and visiting them after the pandemic is under control. I plan to play more golf with my grandson, who I am still trying to beat.

KW: What were some of the biggest challenges you faced during your time at Mitsubishi Electric US, and how did you overcome them?

“The Lord’s Prayer asks us to forgive others. In the elevator industry, it is critical.”

SG: The challenges were mostly the same issues we have today: selling the client on the fact that Mitsubishi Electric systems provide the smoothest ride and most robust equipment in the world, that shipping from Japan is not an issue and that we guarantee provision of sufficient installation and maintenance personnel to provide for emergency callback service within 1 h. We have found that all the Mitsubishi Electric elevators and escalators installed in the U.S. since 1986 are still operating with a service callback rate of fewer than one call per unit per year, except those the owner has elected to modernize or otherwise make a change.

Get more of Elevator World. Sign up for our free e-newsletter.