A New Face for Dubai

May 1, 2020

thyssenkrupp VT enhances visits to Dubai Frame.

Submitted by thyssenkrupp Elevator UAE

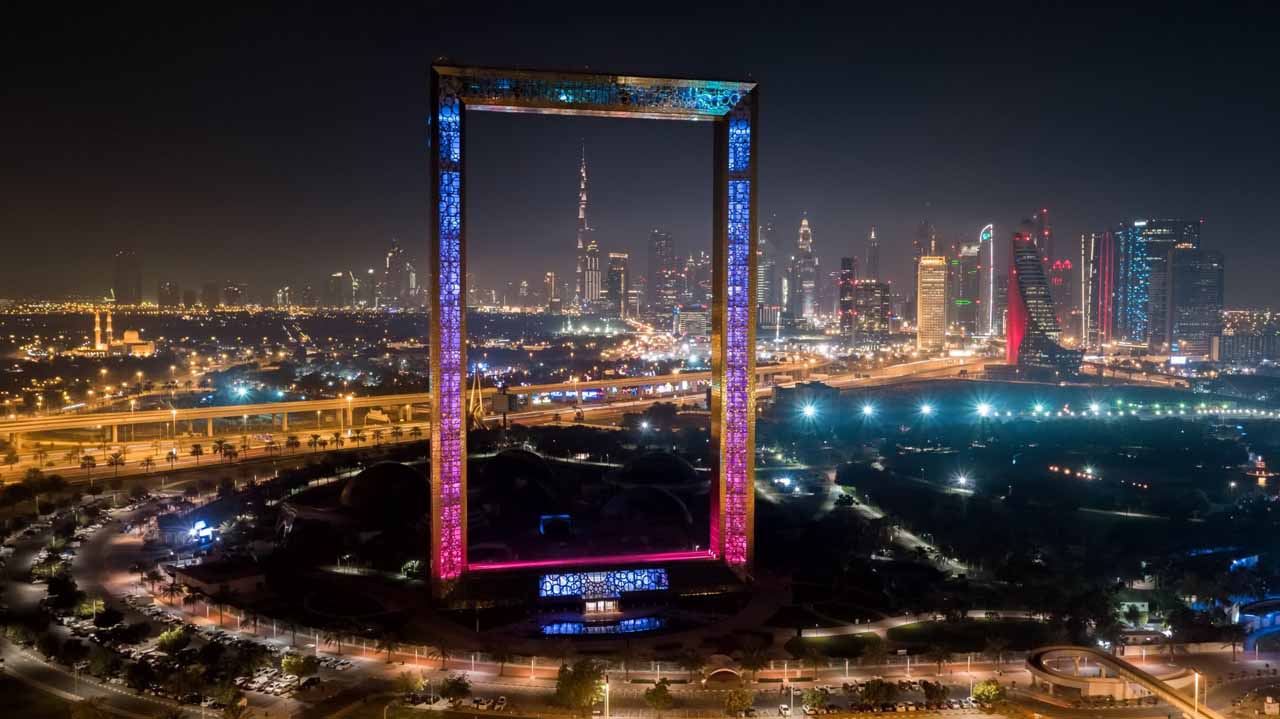

For its 2009 International Architecture Award, thyssenkrupp Elevator asked entrants from around the world to submit a design for a tall, emblematic structure that would promote “the New Face for Dubai.” The contest garnered 926 proposals, and a jury including 11 international architects examined the designs. After a painstaking review, the jurors selected the Dubai Frame, a landmark described as the “biggest picture frame on the planet” that, from its location near the Star Gate of the city’s Zabeel Park, would serve as a bridge between the emirate’s old and new sections.

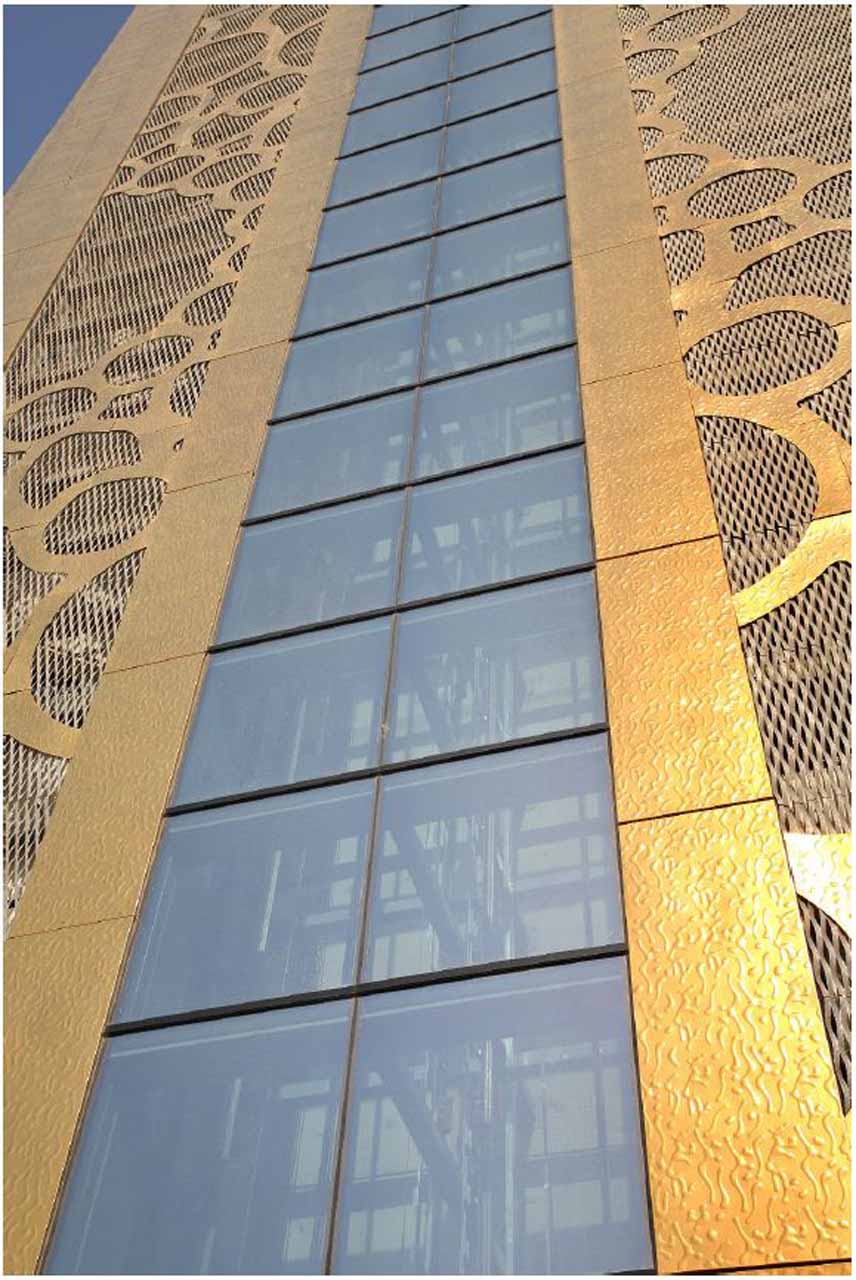

The winning design was submitted by architecture firm DONIS, founded by Fernando Donis, with offices in the Netherlands and Mexico. Donis said that when he was designing the structure, he saw Dubai as a city full of emblems, and, rather than simply adding another one, he saw the project as a way to frame them all. His vision resulted in a four-sided “picture frame” standing a little more than 150 m tall and 95 m wide. Its two legs are connected by horizontal pieces, creating a huge void in the middle, which, depending on where you view it, frames the old city on one side and the sparkling, modern section of high-rise buildings — including Burj Khalifa, the world’s tallest — on the other.

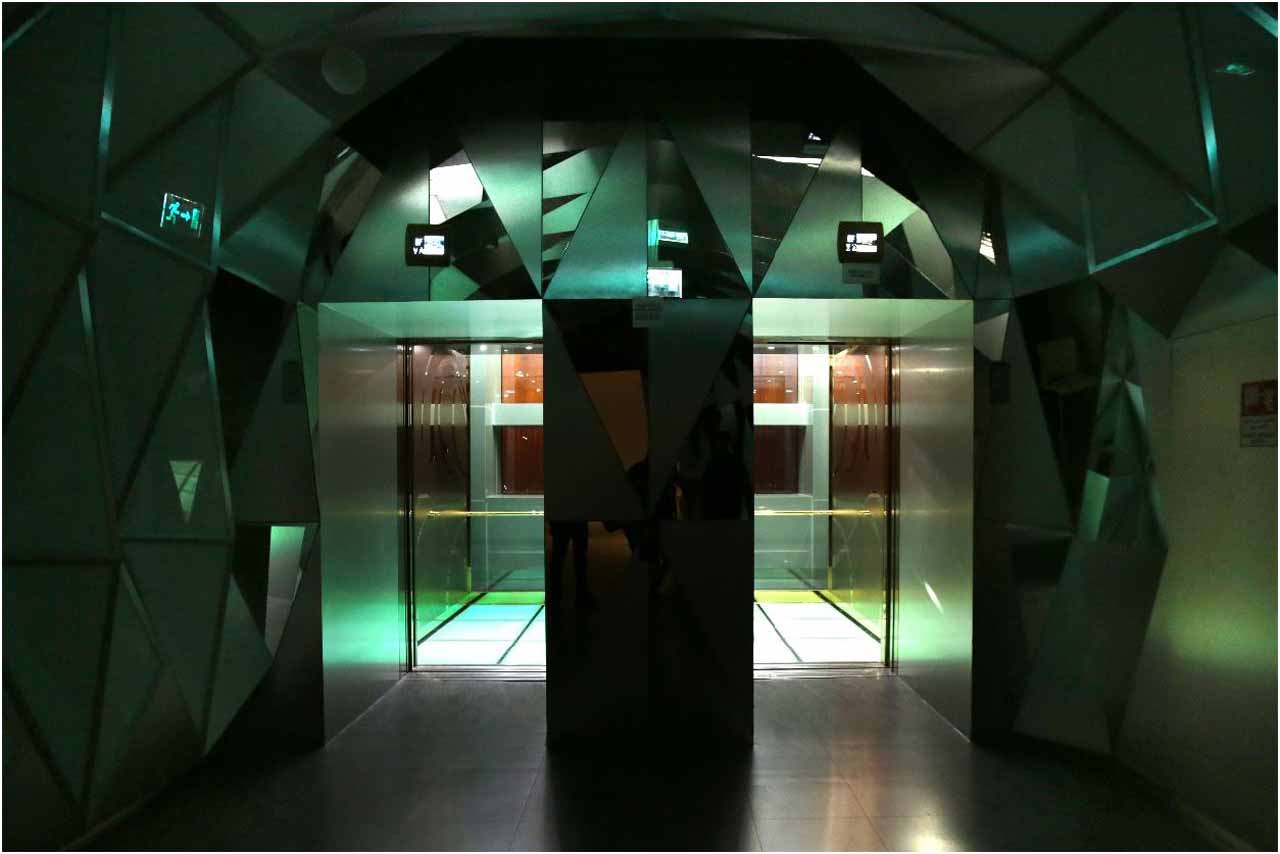

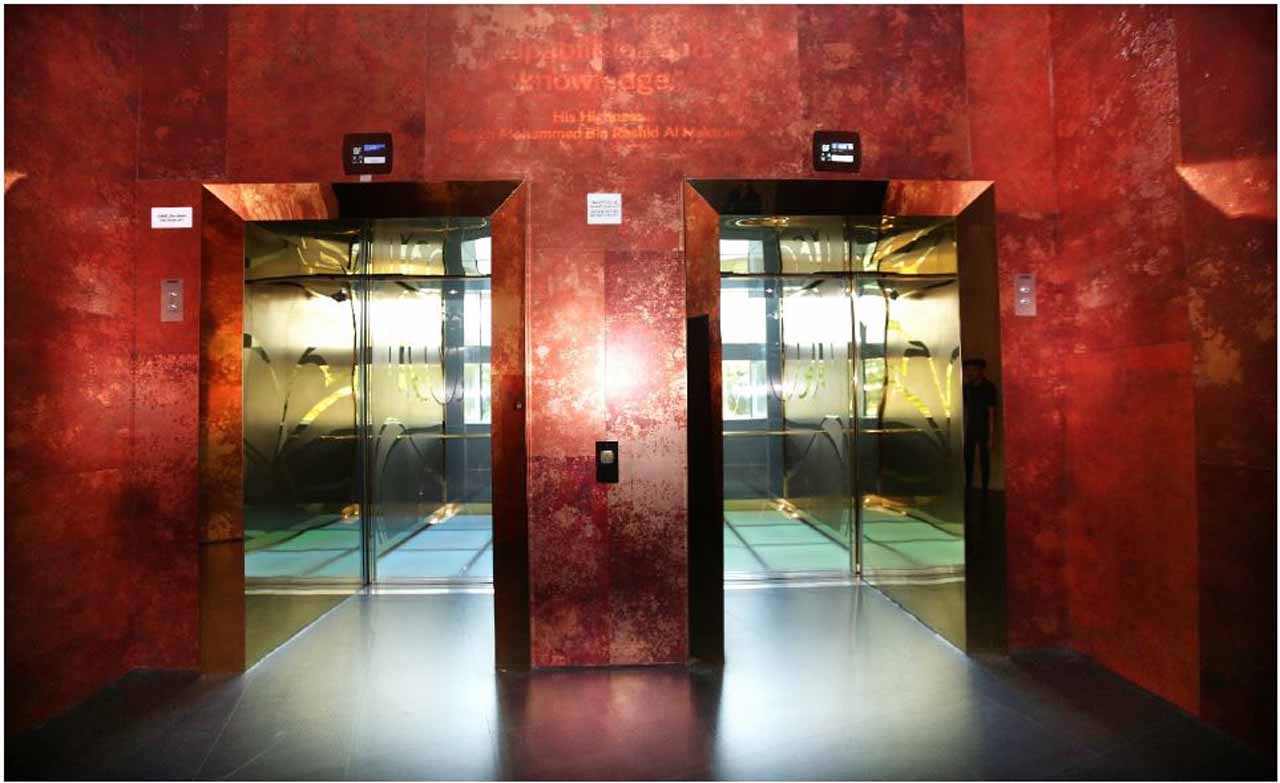

The top section, held aloft by the vertical legs, houses an enclosed skydeck offering sweeping views of the city. Visitors can ride one of four thyssenkrupp panoramic, 3.5-m/s elevators with visual effects incorporated into the floor and walls to offer riders an enhanced experience.

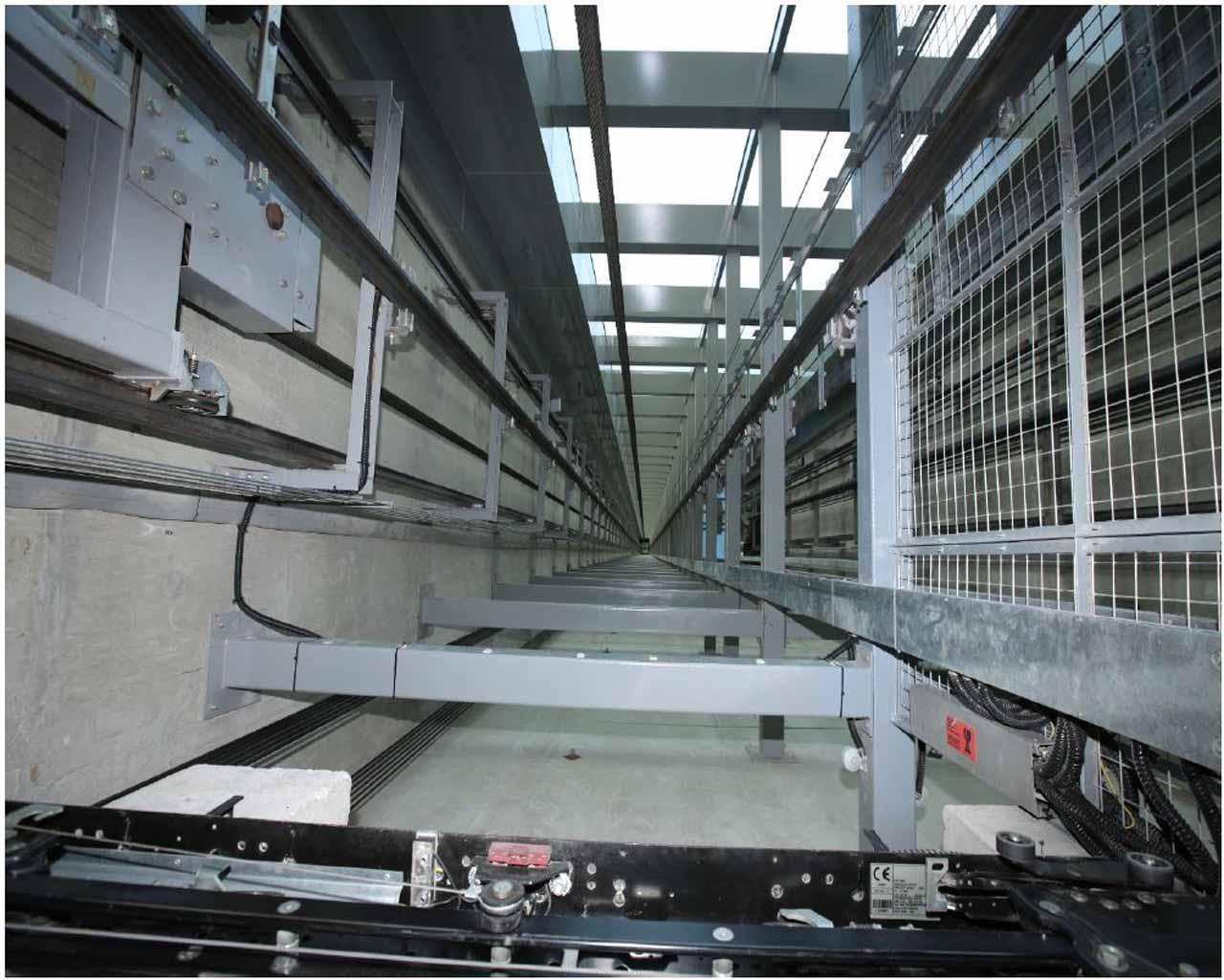

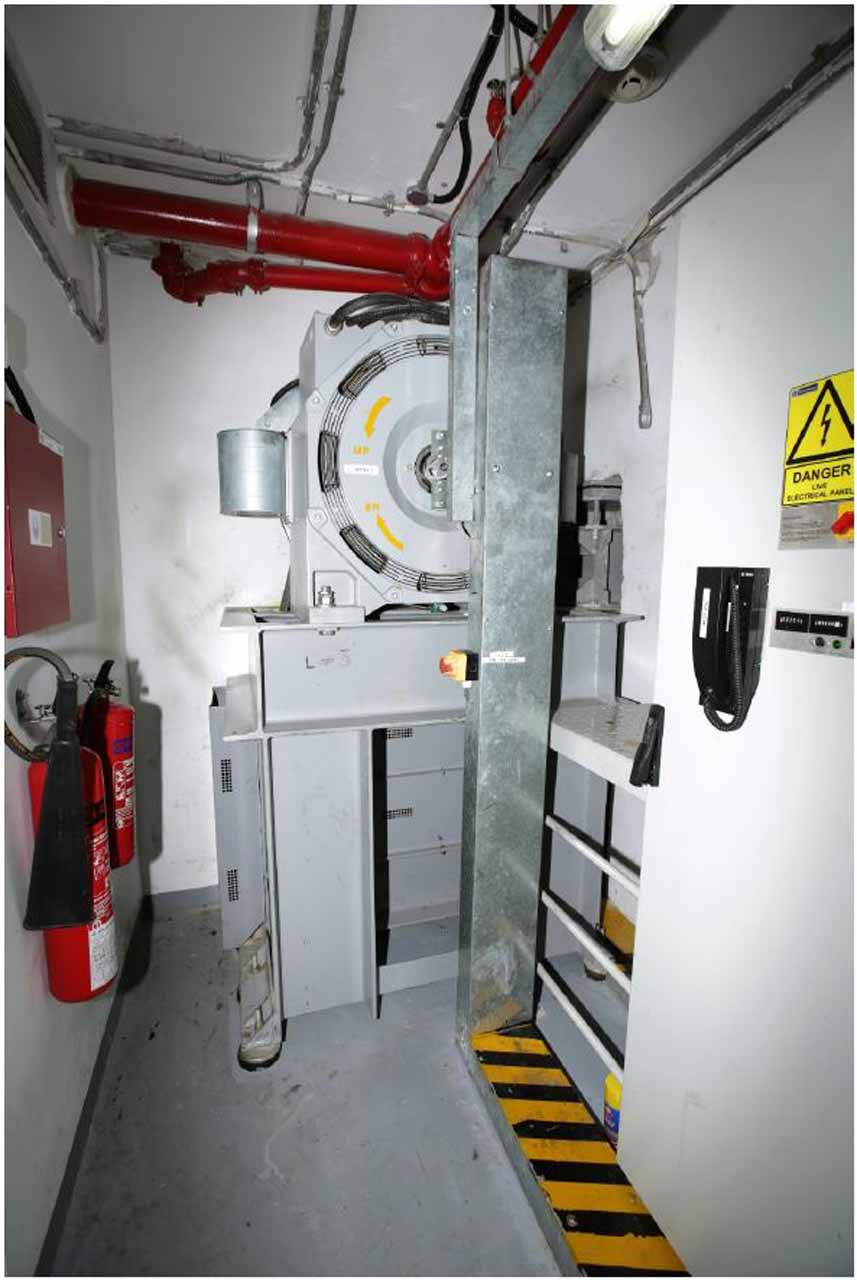

The VT System

thyssenkrupp Elevator UAE was awarded the contract for the vertical-transportation (VT) system at the Dubai Frame in 2012. This project uses four semi-panoramic, machine-room-below (MRB) thyssenkrupp Elevators that carry visitors up and down the 48-story, 141-m height at 3.5 m/s, making the trip in 75 s. There are also two escalators between the ground floor and the first level, where the elevator lobbies are. These escalators move at an average speed of 0.5 m/s, with a capacity of 6,000 people/hr. There is also one accessibility lift traveling between the ground and first level, bringing the VT total to seven thyssenkrupp units. The project commenced in May 2014 and was completed in December 2018.

The Dubai Frame was overseen by Pramod K. Thakare, a project manager with thyssenkrupp Elevator UAE. Thakare, who holds a BE in mechanical engineering, has more than 12 years in the VT industry and has led a number of major projects for thyssenkrupp.

| Unit/No. | Model | Stops | Travel Height (m) | Speed (m/s) | Capacity |

| Passenger lifts (4) | Machine room below | 2 | 141 | 3.5 | 1600 Kg |

| Escalators (2) | Velino | 2 | 3.65 | 0.5 | 6,000 people/hr |

| Accessibility lift (1) | Machine-room-less | 2 | 3.65 | 0.15 | 410 kg |

About the Dubai Frame

- The Dubai Frame measures 150 m high and 93 m wide

- More than 9,900 m3 of reinforced concrete, 2,000 T of steel and 2,900 m2 of laminated glass were used in its construction.

- A ring design made of more than 15,000 m2 of gold-colored stainless-steel covers the Dubai Frame. The design was inspired by Expo 2020 Dubai’s logo.

- The structure’s rectangular design was inspired by the “golden ratio” of 1.618, which many architects and artists believe forms an ideal structural balance.

- The elevator to the skydeck carries visitors 48 floors in 75 s.

- An illuminated floor and a rear-wall panoramic lift cabin offer a visual experience to passengers.

- Car-to-car evacuation technology

Elevators’ Specifications

- Number of units: Four machine-room elevators

- Model: Machine room below at side

- Load: 1600 kg; 21 persons

- Type of Doors: Fully automated, four-panel center-sliding doors

- Travel height: 141 m

- Speed: 3.5 m/s

- Power Supply: 400 V/50 Hz

- Drive System: Electromechanical gearless variable voltage, variable frequency regenerative drive system

- Doors: Fully automatic, four-panel center-sliding stainless-steel (304SB) with light curtain (car); fully automatic, four-panel center-sliding doors (landing)

- Cabin design: Glass walls and ceiling; stainless-steel (441) flooring with red/green/blue decorative lighting

- COP: Vertical step module classic BST push button including Braille symbols and audible/visual call registering

- LOP: Step module classic BST push buttons without arrows; 15-in. EMOTIVE LCD corridor indicators

Challenges

The installation team faced a number of challenges installing the vertical-transportation equipment, including:

- Lift shafts open from rear side, creating difficulty hoisting and aligning rails, especially in windy conditions.

- The two vertical legs were not connected by the skydeck bridge, exacerbating sway and frequently throwing the vertical sections out of plumb, impacting plumb lines and rail alignment.

- The Dubai Frame’s design created space constraints on the machine room at the bottom of the hoistway, making it difficult to get equipment into the room and forcing the placement of inverters outside the machine room.

- Because the four main elevators have only two landings — one at top and one at bottom, with the travel between at 141 m — access and egress of workers, tools and materials were limited.

Reference

[1] Wikipedia. “Dubai Frame” (en.wikipedia.org/wiki/Dubai_Frame)

Get more of Elevator World. Sign up for our free e-newsletter.