Aesthetics for an Icon

Jun 1, 2021

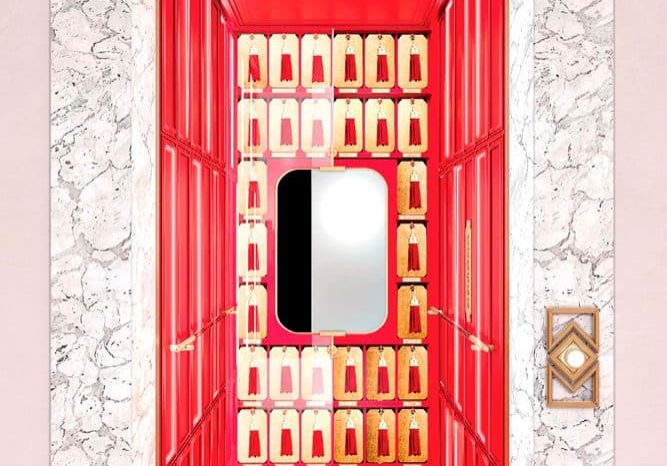

Surfex Coverings describes the process involved in updating a lift system’s look.

submitted by Surfex Coverings

Lift refurbishment company Surfex Coverings Ltd. was called upon by Otis UK for a full lift door and architrave refurbishment at level 20 of Tower 42, Bishopsgate. This is the demonstration level for designers to showcase a new lift theme to the owners. One of the overhaul requirements was to minimise disruption to the building’s traffic and its occupants whilst the works were underway. The lifts had to remain in operation as work was being carried out to transform the lift area and refresh its aesthetics. The main focus was around the preexisting doors and the architrave area.

The Building

At 25 Old Broad Street, Cornhill, London, this iconic building was designed by Richard Seifert and engineered by Pell Frischmann. Originally known as the Natwest Tower after its original tenants, it is the fifth tallest building in London. Its unique shape is due to a cantilevered floorplate design, starting at level four. The floors are designed as three segments that strongly resemble the NatWest Logo. However, Richard Seifert has always said this was just a coincidence.

Iconic and regarded as London’s first true skyscraper, the building brought about many innovative designs, including double-decker lifts.

Construction began in 1971, and the building took nearly 10 years to complete. It was formally opened by Queen Elizabeth II on 11 June 1980. Along with others in the area, the building suffered extensive damage in 1993 as a result of the Bishopsgate bombing by the Irish Republican Army (IRA). The IRA truck bomb caused more than £1 billion in damage to the area, leading to the building very nearly being demolished.

This was deemed too dangerous and expensive, so it was saved by an investment of approximately £75 million.

Natwest later sold the skyscraper, which now houses various commercial tenants. Iconic and regarded as London’s first true skyscraper, the building brought about many innovative designs, including double-decker lifts.

The Company and the Contract

Now being led by its third generation, Surfex is a family-run business founded in the early 1990s by Peter Nye. The main activity is the import and sole distribution of the first-ever self-adhesive architectural vinyl covering, which is produced in Japan. Surfex coverings specialises in refurbishment of cruise-ship interiors and the lift sector.

For the Tower 42 job, Surfex Managing Director Hadley Nye led the inquiry from Otis. The task was to offer the company’s solutions and assist the tower’s design teams in identifying finishes to meet their requirements and design theme. They wanted a new look without the need to replace large architectural components.

Hadley Nye states:

“The beauty of our solutions isn’t just vast the range of more than 600 finishes to choose from, it’s the ability to do a job quickly and in situ so as not to disturb the flow of people. It’s always a pleasure to offer our clients/designers what they want. For many years, the design finishes, especially for the lift sector with a focus on doors/architraves, has been limited. It’s almost become the norm to just have stainless steel or, if you’re lucky, a plain RAL colour. It seems an all-too-familiar story that it is the forgotten part of the building in design finishes. Clients have just gotten used to the boring options available. Add that to the cost and inconvenience of having to shut the lift down with hoardings, etc., and it can be a real nightmare. Not anymore. We can offer everything from McDonald’s yellow to 18-carat gold and, more importantly, fit this in situ. One of our installers can typically, on his own, refurbish four sets of doors a day. So you get an idea of how quickly we can operate throughout a building, with little to no disruption.”

Scope of Works

The main design requirements for this project were that doors and architraves remain, without the need for hoardings, and for the lifts to remain operational. Designers were sent metal sample plates of their selections of black-and-white leather, matte, gloss and wood. In the end, a textured matte black-and-white covering was selected.

The Surfex team worked alongside and in collaboration with Otis, which would isolate the lift when needed whilst the installation was underway. Preparation began by thoroughly filling all the dents and scratches, bringing the doors back to a smooth surface. “Ninety percent of decoration is preparation, and, as long as you get that perfect, the installation is straightforward,” Hadley Nye observes.

The areas were then vigorously cleaned to eliminate residue and grease buildup. Material was cut onsite to the exact dimensions. The product meets all standard lift requirements. It has been tested and approved by the largest global lift companies. It also has certificates for marine use and passes all relevant codes. It is endorsed by David Cooper.

How it works is a technician peels the material’s backing paper off, sticks it to the door front and squeezes out excess air, making sure to apply pressure and heat around the edges. “You can mould around any 3D surfaces with detail; you can wrap a builder’s hat if you wanted,” Hadley Nye says. “This gives you an idea of the flexibility of the product and its capabilities, so lift doors and architraves are a dream scenario.” Each lift door then typically takes around one hour to cover.

Refurbishment Challenges

The goal was to have the test area completed from initial inquiry, pattern selection to finish within two weeks. Hadley Nye states:

“We are used to bespoke requirements and offering our clients everything possible, as we are a one-stop refurbishment shop. Having so many finishes can be a curse, as well as a godsend. On this occasion, we were able to assist the client and designers with their preferred finishes, as they had already selected a theme. The transformation looks amazing and was completed before the deadline. The management company, designers and owner are all happy with the new look. Now, it’s on to the other 41 levels!”

Get more of Elevator World. Sign up for our free e-newsletter.