Style, design and safety distinguish available gear.

POTS Replacement

Ooma, Inc., a cloud-based communications provider based in Sunnyvale, California, has introduced Ooma AirDial, a solution for businesses that addresses the looming retirement of legacy copper-wire analog phone service, also known as plain old telephone service (POTS). The phasing out of POTS affects critical safety and business-critical systems, including elevator phones. Available in the U.S. only in early 2022, Ooma AirDial combines phone service, a T-Mobile data connection and hardware in a single, easy-to-install and manage package. Systems that today require a POTS line — such as elevator phones, public safety phones, building access systems and more — can be quickly and easily migrated to a digital connection. Because Ooma AirDial will maintain a managed voice channel that doesn’t touch the public internet, the solution is expected to meet regulatory requirements such as NFPA 72 and UL 864 for life-safety systems. Features include:

- Up to four analog connections with standard dial tone and full backward compatibility with POTS

- Options for either an exclusively wireless connection or failover from a wired broadband connection to wireless

- Backup battery that will maintain service for 8 h or more during an outage

- LCD display that shows wireless signal strength, battery status and phone line status

- Remote management across multiple locations through an online portal, with the option to set automated alerts for events such as outages and batteries that need replacement

- Heat sink and ventilation for fan-less cooling

- Support for external antennas for installations where the AirDial unit isn’t near the exterior of a building

- Number porting

- Mounting that can be either vertical (wall) or horizontal (table)

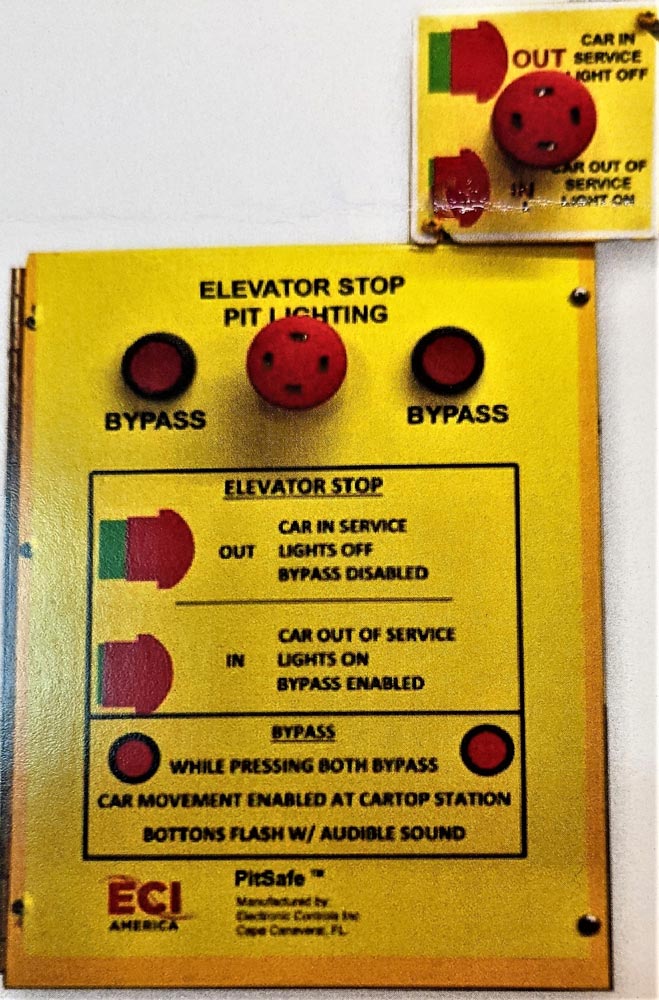

Pit Safety Switch

Anyone who maintains, repairs or inspects elevators knows the need for safety, and this is no more true than inside the pit. Working in a pit means working within a dark, confined area. Before entering the pit, personnel usually must turn on the light, but if this is done before the pit stop switch has been activated, it’s possible that the person on duty will step into a dangerous situation in which the elevator can unexpectedly descend, causing serious injury or even death. To greatly reduce the possibility of this happening, ECI America has developed the PitSafe™ device, a switch that combines pit illumination with motion stopping to prevent a person from entering an unsafe situation. PitSafe offers:

- A switch that simultaneously activates pit light and elevator motion stopping

- A “Fail-safe” function that is superior to less-capable on/off light switches

- Elimination of unintended motion by deactivating the car-top inspection station while a worker is inside the pit

- Intentional movement control that brings the elevator to the proper height for maintenance. This allows the person inside the pit to activate movement by pressing two buttons; releasing either button halts the movement.

- Emergency battery backup for the pit LED lighting system, allowing for emergency exiting during power failure

- PitSafe operates on 120 VAC and is available with an optional audible alarm for water and oil.

Cabin Contaminant Fighter

SecureAire Technologies, LLC of Dunedin, Florida, has developed the EU-100X Elevator Air Purification System that uses Active Particle Control (APC) to protect passengers from all airborne contaminants: particles, total volatile organic compounds, smoke and pathogens, including viral particles such as those that spread COVID-19 and other potential ailments, the company announced in October. SecureAire’s APC solution uses patented energy-field technology to increase the efficiency and effectiveness of its proprietary filtration media. It provides pathogen destruction and inactivation benefits through its INACTIVATE™ Technology. APC combines electrostatic and electrodynamic fields to make airflow the dominant transport mechanism for airborne particles. The EU-100X unit has a fan, a replaceable SecureAire cartridge and a variable-speed airflow controller. This complete system can deliver up to 600 f3/min of particle-free air. The system offers effective air purification through three components: particle coagulation, which overcomes forces that hold airborne contaminants within a space; optimized air change rate, which brings particles back to the filter for removal or sends them to a dedicated exhaust for enhanced ventilation; and high-efficiency filtration, which helps remove particles while maintaining a safe, healthful and clean elevator environment.

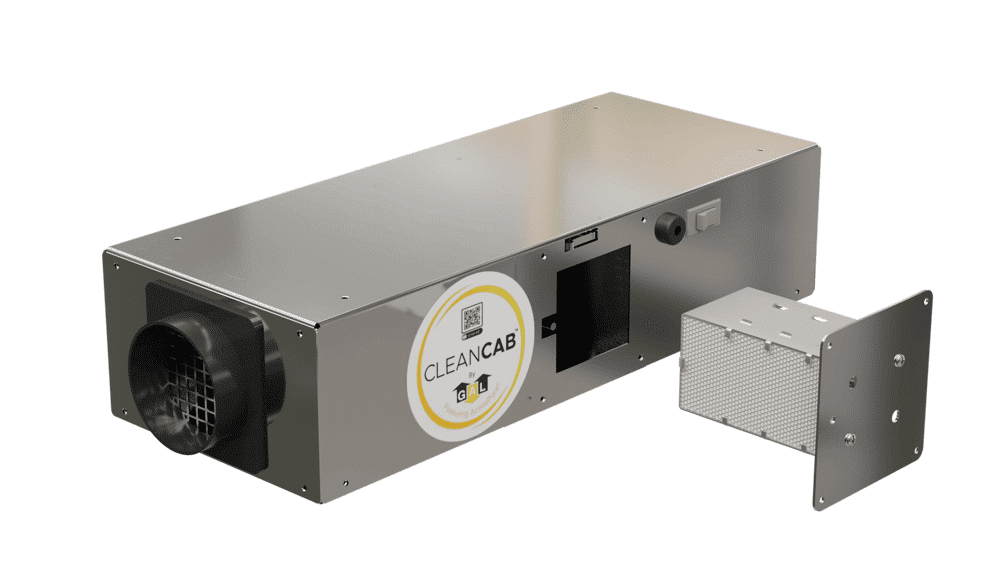

Cabin Sanitation

North American workers and students have begun to return to offices and classrooms, but, for many, the important factor is whether they can feel confident stepping back into elevators. Bronx, NY-based GAL says they can when they are riding an elevator using the company’s CleanCab™, featuring ActivePure Technology®. CleanCab is a new purification device powered by ActivePure that offers 24/7/365 neutralization of viruses in the air and on surfaces, including SARS-CoV-2, the virus that causes COVID-19. CleanCab works by pulling oxygen and water molecules through ActivePure’s patented honeycomb matrix, where powerful oxidizers, known as ActivePure Molecules, are created. The ActivePure Molecules are then released back into the elevator cab, where they vigorously neutralize such pathogens as MS2 Bacteriophage RNA virus, Staphylococcus Epidermidis, and others on cab surfaces and in the air. ActivePure Technology was tested on live SARS-CoV-2 virus — not proxy or surrogate strains used by many competing technologies. This system has been proven to reduce more than 99% of virus and other surface contaminants. CleanCab also eliminates ozone and works quietly. It offers measurable results and has been used by businesses that have a high risk of transmission.

Get more of Elevator World. Sign up for our free e-newsletter.