Analysis of the Ecological Footprint of Different Drive Systems for Elevators

Jun 1, 2011

An examination of the process, results and conclusion of comparing the ecological footprint of two different drive systems

Introduction

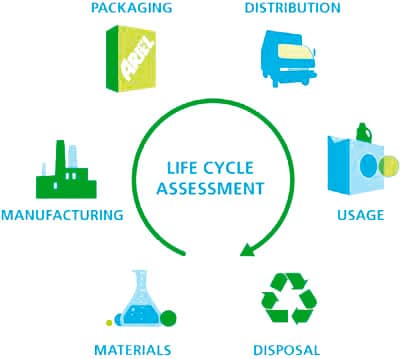

For years, Bucher Hydraulics has been at the forefront of the development of energy-efficient and sustain-able hydraulic solutions. We are, therefore, convinced of the need for serious analysis of our products. We arranged for a study of the lifetime use of the product, from manufacture to disposal. This study was per-formed using the life cycle assessment (LCA) method, together with the University of Applied Sciences Northern Switzerland, FHNW. The data collected allows for a sustain-ability comparison between a gear-less traction machine-room-less drive system and a hydraulic drive system with electronic control. Process (Methodology)

The LCA method, based on ISO Standard 14040:2006, allows for the ecological and economic comparison of the two different drive systems. The basis (functional unit) is a standard passenger elevator for an apartment building with a 675 kg rated load (eight people) and a rated speed of 1 mps over a distance of 15 m. Such elevators are typically used infrequently, because the tenants normally use the elevator morning and evening. This gives approximately 120 rides per day or 43,000 per year (usage category 1 according to VDI 4707). The average lifetime of the system is assumed to be 20 years. Components common to both systems, such as the cabin, doors, etc., will be disregarded for this analysis.

The ecological analysis of the two systems is done using the European method: Eco-Indicator 99 and analysis software SimaPro7. This method of analysis is well suited to industrial products and is widely used inter -nationally. Measurement and qualification are done using Eco-Indicator Points (EIP, see Infobox), also known as (environmental) impact points.

Results

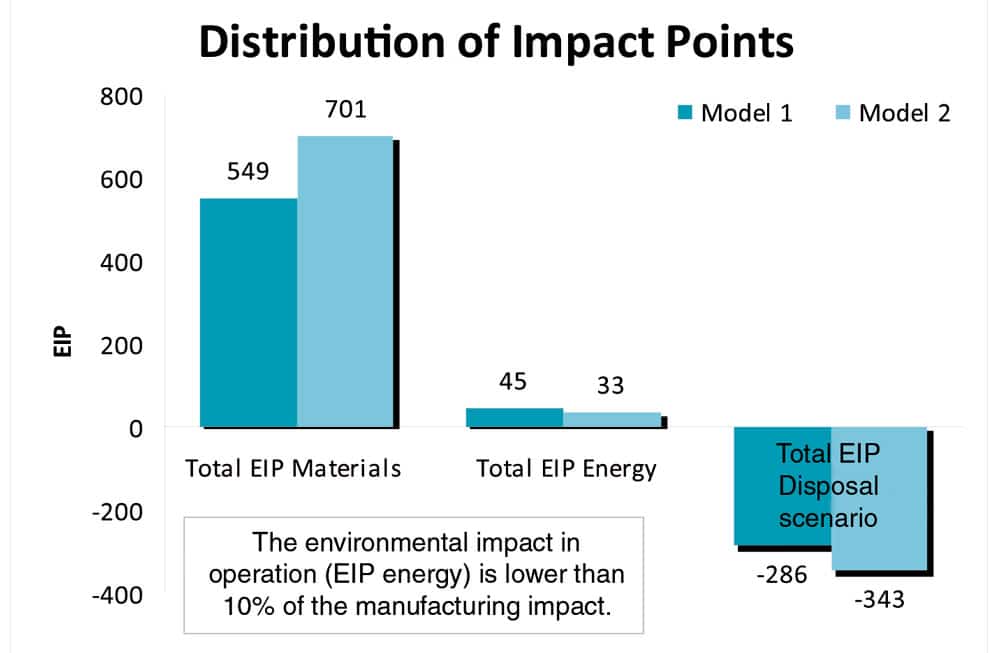

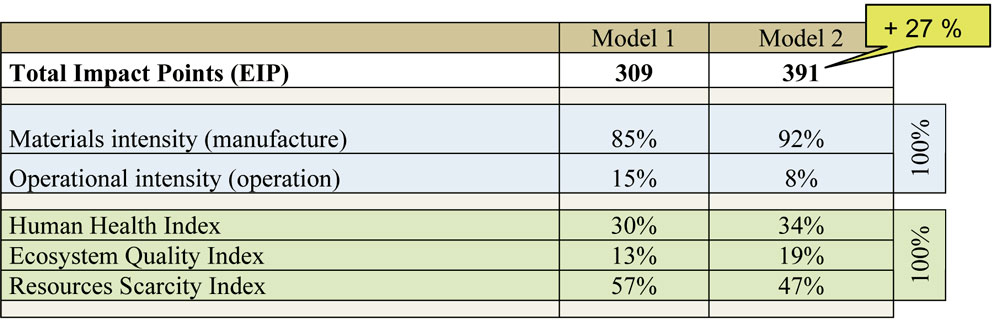

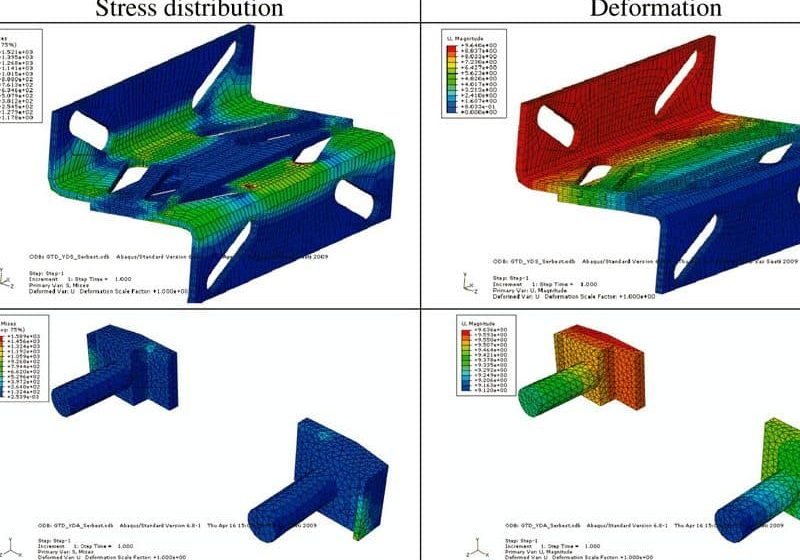

At the end of the LCA, a definitive number of impact points result for the hydraulic drive system (Model 1) and the traction drive system (Model 2) relating to manufacturing, lifetime use and safe disposal of the materials (Figure 2).

- Total EIP materials (manufacturing): Model 2 has significantly more impact points for manufacture and installation. This is due to the more complex design with counterweight and higher proportion of electronic equipment (variable-frequency drive).

- Total EIP electricity (operation): Model 1 has marginally higher impact points during operation (energy consumption) than Model 2. This is due to higher energy consumption during the up ride (no counterweight). The over-all difference is negligible, because Model 2 has a much higher standby demand, which carries more weight for Usage Category 1.

- EIP disposal scenario (recycling): For both systems, impact points can be reduced by approximately 50% if the materials are properly recycled at the end of the system lifetime.

Final assessment of both systems, assuming correct recycling:

This synopsis shows that Model 2 impacts the environment approximately 27% more than Model 1. Operational energy use carries less weight than materials use in this case.

Conclusion

- LCA shows that, after comprehensive analysis, the sustainability of hydraulic elevator drives compares favorably to traction drives.

- The environmental impact of the manufacture and installation of an elevator drive is significantly higher than the impact of energy use during operation.

- A partial modernization is often the more sustainable approach, due to the higher materials impact during manufacturing. Complete replacement of a hydraulic elevator with a traction elevator in order to save energy during operation is a poor choice from an ecological point of view, as explained by the analysis.

LCA Using Eco-Indicator 99

Eco-Indicator 99 is a comprehensive and effect-oriented qualification method. The Eco-Indicator is a measure of the detrimental effect on the environment. Qualification takes place using Eco- Indicator Points (EIP), also known as impact points. The absolute value is not relevant; more important are the relative differences for comparison. The Eco-Indicator 99 method defines three impact areas:

- Human health (climate change, ozone-layer depletion, carcinogenic effects, breathing problems, ionizing radiation)

- Ecosystem quality (species diversity, ecotoxicity, surplus acidity, eutrophication, land use)

- Availability of resources

Get more of Elevator World. Sign up for our free e-newsletter.