Application Research of Advanced Manufacturing Technology in Escalator Manufacturing

Mar 1, 2017

An overview of associated technology in China, the world’s biggest escalator manufacturing location, and Chinese manufacturer CST

by Wang Qibing, Leng Yonggang and Lee Yu

Along with the rapid development of China’s economy and the vigorous promotion of urbanization, the development of escalator manufacturing keeps growing at double digits. According to data released by the China Escalator Association, compared with 529,000 in 2012, a total of 633,000 escalators were produced in the industry in 2013, with a net gain of 104,000. With a growth rate of 19.6%, the number of installed escalators in the market was 2.45 million in 2012. This number broke three million in 2013 (an increase of 22.4%).

According to data released by the International Organization for Standardization, there were 12 million escalators in China in 2013, which was the first time per-capita ownership of escalators in the country was up to the average level of the world. There are more than 600 escalator manufacturers in China, making up a CNY100-billion (US$14.71-billion) -per-year segment.

Improving the level of escalator manufacturing is the necessary trend for the sustainable development of the national escalator industry.

The escalator is becoming an important symbol of modern urbanization and advanced rail transportation equipment. Escalator manufacturing is important in the modernization of the manufacturing industry. The segment must keep pace with such technological innovation as 3D printing, mobile Internet, cloud computing, big data, biological engineering, and new forms of energy and materials. The manufacturing of intelligent equipment and intelligent factories based on the physical information system is leading the revolution of manufacturing, which is supported by the 2015 policy document “Made in China 2025.” The domestic escalator industry kept growing vigorously, bringing demand for the acceleration of innovation and manufacturing within it.

Basic Situation of Advanced Manufacturing Technology

Market Situation

Along with the rapid development of advanced manufacturing technology, the quality of the equipment for supporting advanced rail transportation has been improved; meanwhile, it is the hard index for advanced manufacturing technology entering escalator manufacturing. This brings changes that include computer-aided design and manufacturing and an integrated advanced technology ecosystem. Though the application of advanced manufacturing technology may help the manufacturer obtain a strong advantage in market competition, manufacturers still need to depend on organization and the full play of technology to reach unified coordination and integration. Therefore, improving the level of escalator manufacturing is the necessary trend for the sustainable development of the national escalator industry.

Current Situation in China’s Escalator Industry

Due to the relatively late start of Chinese industrialization, compared with the level of industrialization of other developed countries, there is still a big gap between China’s manufacturing industry and advanced manufacturing technology.

Characteristics of Advanced Manufacturing Technology

Development

“Advanced manufacturing technology” is considered the latest stage of traditional manufacturing technology development. It not only keeps the effective factors of old manufacturing technology, but also constantly absorbs all kinds of high-tech achievements, penetrating into all areas of production. New intellectual manufacturing technology will be constantly updated with the progress of science and technology.[1]

Industrial Application

New methods of manufacturing are important means of developing new products and technology. They play important roles in the industrial enterprise, bringing considerable economic and social benefits. Instead of aiming at only what is the newest, advanced manufacturing technology focuses on the most practical result of the combination of technology, management and science. It is concerned with simplification and justification for the organizational and management system during the production process, thus promoting an advanced manufacturing level to increase an enterprise’s comprehensive market competitiveness, promoting economic and national industry development.

Globalization

The globalization and informatization of the manufacturing industry allows every country’s manufacturing industry to have a stable development in the international market through advanced manufacturing technology. Therefore, this influences the manufacturing enterprise, with one prime example being the introduction of computer-aided design (CAD) technology in 1986.

Application of Advanced Manufacturing Technology

Group Technology

In escalator manufacturing, group technology is the foundation of computer-aided manufacturing, which organically integrated the whole system such as R&D, product manufacturing, enterprise management, etc. It broke the conventional production mold, which, with more models and less production, resulted in maturation of the enterprise. The core of group technology is the group process, which integrated the parts that were similar in structure, material and process into a parts family (group), increasing productivity and efficiency.[2]

For example, CST Escalator Manufacturing Co. has carried out Lean manufacture management based on the group technology. With the group technology, it has coded all of the non-standardized parts and established a database, a new-parts structure design, a process plan, a production preparation and processing that references the documents of parts with the same or similar code. The application of the group technology has laid a solid foundation for implementation of group technology. It is used on the delivery rate for materials procurement, structure parameters of parts, requirements of performance and dimensions since the date of scheduling in the contract. For example, components are generated with optimized technique drawings, and by adjustment of drawings with similar parts, production process and tooling, followed by ordering purchasing or processing. The process of unit production and exchange of raw-materials purchasing, production, purchasing, technology and R&D is based on the previous technical data of similar products to solve the problems as soon as possible and realize the concurrent engineering.

Most products in the company are to be produced in a just-in-time manner based on the contract, while others are produced per the schedule based on customer requirements. Reverse time was used for arrangement of the technology processing, procurement of raw materials, spare-parts processing, packing and transportation per the contract delivery time, while, after the application of group technology, the time for manufacturing the components has been greatly shortened.

Artificial Intelligence

Different types of enterprises vary in both depth and width on popularization of advanced technology, especially for informatization. The design of escalators is complicated, depending on the rich design experience and application process level of engineering technical personnel. In the design phase, they do not only solve deterministic problems based on algorithms, but also the non-determinacy problems based on the knowledge and rules. Along with the application of CAD technology in escalator design, it requires a computer to substitute people for solving the uncertainty problem.

The optimized design of escalators’ support manufactured by CST applies the calculation software of NX Nastran, MSC Nastran, Abaqus, Ansys, Hyperworks and the EN 1993 (GB 50017) standards of steel structure design and “security specifications of manufacturing and installation of escalator and moving sidewalk,” etc., by the method of tension (EN 1993-1-1/6.3.1) (Figure 2).

Research shows that, as lifting equipment is used by the public, the escalator must be calculated precisely with all kinds of maximum loads or pressure in idle. To guarantee this in the production cycle, the application of informatization technology plays an important role in technical research, supporting the process of large public escalator design and manufacture.

Concurrent Engineering

Concurrent engineering integrates design to define data-management variables through digital product models. During the early stages of traditional product design, determining a product’s lifecycle is not easy, while with concurrent engineering, design, process and early stage of production can be integrated. Using a computer, the production cycle (Figure 3, second diagram) is greatly shortened, and the problems appearing in early stages can be solved. Thus, the quality of design, process and production is guaranteed, and a great deal of reworking is avoided.

Escalators are high-end, complex equipment, the involved development technology of which can be time consuming. Production cycle, product quality and cost control in escalator development are particularly important, considering the tense competition of the market. Most national brands only imitate other enterprises, due to their lack of investment capital toward product development, so the products put on the market cannot be verified in early stages of technology development. Thus, there is still a big gap between national products versus those from overseas. Particularly, investing funds in product development and establishment of organizational technology are required for Chinese escalator industries to shorten the cycle of development of escalator technology, improve product quality and decrease the costs of product development.

Escalator development may be divided into six technical standpoints: planning, R&D, verification of component tests, sample trial manufacture, small-group testing and acceptance of the whole unit. Spot checking finished escalators before they leave the factory should include quality and performance, national laws and regulations, and customer standards. Defective products should be isolated and identified onsite. Related departments should be urged to take corrective measures as soon as possible. Then, the customer should be notified of any model defects. In addition, the escalators should be tested over time on safety and reliability by the manufacturer.[5]

Feature Technology

“Feature technology” is a prototype integrated with the latest achievements of new technology, such as CAD/CAM, laser processing, numerical control and new materials. The prototype of the part to be manufactured can be generated directly using 3D CAD model data, which can be easily modified to produce the new prototype. Different from the traditional parts of manufacturing, which need wood, plastic, ceramic, etc., it shortens the time of making a prototype from a few days to a few hours, improving the product-development cycle. For example, during the design of a towing unit by CST, the solid 3D model analysis of a finite element is established to solve the natural frequency and vibration of each order to adjust the distribution of the natural frequency of each shell and reduce the co-oscillation from rotational frequency and transmission caused by the gears and gear worms. The correctness of imitation is verified through the modal experiment shown in Figure 3, which provides the reference for dynamic design and optimization of multiple angles and body sides (Figure 4).

Agile Manufacturing (AM)

AM establishes the company’s employees, supporting manufacturers with assistance in manufacturing, agents and affiliates. Based on the computer network, information set and character of development of cooperation, a virtual task-oriented corporation is established to realize fast and optimal production.[2]

Conclusion

This study described the specific content of the application with such advanced technologies as group technology, AI, concurrent engineering, technical features and AM in the escalator manufacturing process. It has described its effect on optimal design in escalator-manufacturing support and the design of escalator towing units during manufacturing. These effects can improve escalator manufacturing and technology development. By verification via implementation, it can be seen that the advanced manufacturing technology has played a significant role in promotion of the industrial base of escalator manufacturing in China, transferring to innovation in the industrial base and driving the sustainable development of the global escalator industry.

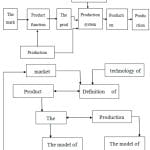

- Figure 1: Flowchart of Lean manufacturing of CST’s company-based group technology

- Figure 2: The strength check for CST’s escalator supports: (top to bottom) excessive stress on the elbow of the upper-lever section; excessive stress on the angle iron on the up-and-down head; comparing excessive stresses

- Figure 3: Management charts of CST’s concurrent engineering: (top to bottom) traditional and concurrent design processes

- Figure 4: Modal analysis on CST towing-unit characteristics: (top to bottom) structural model, simulation modal shape and testing modal shape

References

[1] Zhou Jun & Mao Jian. “Advanced Manufacturing Technology.”

[2] Zhang Lei. “The Development of Advanced Manufacturing Technology” (2009).

[3] Hu Haiyan. “The Lean Production Methods and Examples Based on Group Technology,” (2002).

[4] Saberi S., Yusuff R.M., Zulkifli N, et al. “Effective Factors on Advanced Manufacturing Technology Implementation Performance: Review,” Journal of Applied Sciences (2010) 10(13), p. 29-42.

[5] Zhong Yuan. “Design Guideline of Product Oriented to Manufacturing and Assembly.”

[6] Li Changwen. “The Application of Advanced Manufacturing Technology in Mechanical Manufacturing Industry” (2009) (03).

Get more of Elevator World. Sign up for our free e-newsletter.