Experts take a close look at lifts and earthquakes during 11th Lift Symposium in İzmir, Türkiye.

The 11th Lift Symposium, which has become traditional under the umbrella of Izmir Branch on behalf of the TMMOB Chamber of Electrical Engineers and the Chamber of Mechanical Engineers — which has organized several events for the lift and escalator industry since 1993 — was held on October 17-19, 2024, at the MMO Tepekule Congress and Exhibition Center with the theme of “Earthquake and Lift.”

The first day of the Lift Symposium, which is the most important platform for sharing technological innovations, practices and knowledge on the area of lifts in our country, started with a beautiful musical recital in tune hejaz by Bülent Çarşıbaşı, Prof. Dr. Firuz Balkan and Opr. D. Ahmet Çubuklusu in the Anatolian Hall of the MMO Tepekule Congress and Exhibition Center. Subsequently, after the national anthem and a moment of silence, the opening speeches began.

MMO Izmir Branch Board Chairman Ziya Haktan Karadeniz, the first to take the stage in the opening speech, shared information about the history of the symposium and this year’s program. Then, EMO Izmir Board Chairman Gülhan Güler took the stage. Güler said that while production technology is showing extraordinary developments worldwide, and there is an extraordinary global acceleration in scientific and technological developments due to neoliberal economic policies, we are experiencing a period of stagnation in our country. Güler said:

“We see that especially our young colleagues are being forced into a brain drain in a process where we are confined to imported technology and equipment in almost every area despite our trained workforce.”

Afterwards, MMO Board Chairman Yunus Yener came to the stage to make the opening speech and gave information about the intensive activities they carried out in the lift industry as a chamber. Yener said:

“Preventing loss of life and property during earthquakes is possible by fully fulfilling the duties of engineering disciplines in this regard. Therefore, it is of utmost importance that lifts are designed, installed and regularly maintained to be resistant to earthquake’s impacts.”

Then, EMO Board Chairman Mr. Mahir Ulutaş took the stage and stated that, unfortunately, due to the wrong economic policies that have been pursued for many years, our country is an open market for high-tech products in the field of lifts, as in almost every other field. Ulutaş said:

“In recent years, there has been a significant increase in the number of escalators and moving sidewalks in public buildings. Escalators and moving sidewalks are imported and operated quite easily from the Far East within the framework of machinery safety regulations. It is obvious that there is still a legislation hole regarding inspection and examination in these products. An urgent study should be initiated for the installation, operation, registration and inspection of the escalators and moving sidewalks.”

Following the opening speeches, the symposium and exhibition areas were opened with a ribbon cutting ceremony.

The First Session

The first session after the coffee break started under the moderation of Bülent Çarşıbaşı.

The first presentation was delivered by Erol Uyar from the Ege University Electrical and Electronics Engineering Department under the title of “Lift Movement Dynamics and Simulation.” He gave important information on today’s educational deficiencies as an experienced professor. Stating that the basis of education is physics and mathematics, he said, “Without these two, neither a technical person nor an engineer can be trained.”

The second presentation titled “Lift Machine Chassis Design Studies” was made by Şamil Çahal from Has Asansör. Çahal started his presentation with the company history and explained how they designed and developed the machine chassis. Following the presentation, questions and scientific criticisms on vibration and sound insulation revealed that they need to work on the subjects mentioned in the presentation.

The last presentation of the first session was made by Metroplast Founding General Manager Levent Akdemir on “Safety Problems and Solution Suggestions in Lift Brake Systems.” Akdemir, who started his words by saying, “I am in the industrial estate, I have been working with iron for about 40 years,” stated that while the lift brakes, which are the only elements we trust to ensure safety in case of any fall of the lift, passed the full load test conducted in the field, many brakes on the market failed the free fall tests undertaken in the lift test tower. Akdemir underlined that the main problem is that the tests performed before the free fall situation occurred did not meet the safety requirements.

The Second Session

After lunch, the first presentation of the session moderated by Süleyman Varol was made by Dr. Ferhat Çelik from Blain Hydraulics on “Lift Safety in Seismic Regions.” At the beginning of his presentation, Çelik said that the sector report prepared by the ministry states that there is a high level of dependency on foreign countries for hydraulic lifts, but he added that it is regrettable that the research conducted by the companies is not included in this report as required. He stated that there are many hydraulic component manufacturers in our country and the dependency on foreign countries is only between 8%-17%. He then also gave information on EN 81-77. He exhibited the examples that should be taken in lifts according to the three earthquake categories in the standard, with pictures taken in the field during the Malatya and Van earthquakes. Çelik stated that the main problem they observed in both earthquakes was the damage caused by the displaced counterweights. He also observed that hydraulic lifts without counterweights were safer than electric lifts.

The second presentation of the second session was made by Mehmet Yücelay from Eskişehir Technical University on “Strength Calculations for Lift Components Not Calculated in ISO 8100-1/2 (EN 81-20/50).” Yücelay said in his presentation that the strength calculations of some components used in the lift industry in Türkiye are not included in the EN 81-20/50 standards; therefore, the most basic and only source that can be used for the calculations of such components is the TS 1812 standard, which was published in December 1988 and is still in force. However, he said that the adequacy and up-to-dateness of this old Turkish standard (TS 1812) poses a problem for local companies that export to Europe or want to increase the quality of their products, and he explained with detailed examples that TS 1812 contains deficiencies in some areas. Mehmet Yücelay, who contributed to the development of the Eleport software project, also received questions about Eleport.

The subsequent presentation titled “Lifts in the February 6, 2023, Earthquake Region,” which was planned to be made by Kerem Şahin, was made by moderator Süleyman Varol, as Kerem Şahin could not attend. In the presentation, the damage to the lifts during the February 6 earthquake was exhibited with pictures taken from the field.

Taking the stage in the question-and-answer session, İlyas Menderes Büyüklü from the Ministry of Industry asked the industry members in the hall how to prevent the sale of second-hand products such as engines and panels collected from collapsed or severely damaged buildings in the region after the earthquake. At this point, a consensus has been reached that such an industry has unfortunately been formed and that serious measures must be taken to prevent it.

Forum

As the last session of the day, forum started under the moderation of the TASFED Chairman Cem Bozdağ. At the forum, Mustafa Gürel from the General Directorate of Industrial Products of the Ministry of Industry and Technology delivered the “Lift Operation and Maintenance Regulation Information Presentation.” He elaborated on the stages regarding the operation process and placing on the market of the lifts in his educational presentation. One of the most important opinions received during the question-answer session was the importance of sharing the feedback from 36 accredited inspection organizations operating in the country, primarily MMO and TSE, with the ministry. Menderes Büyüklü, who took the floor, said that regular feedback on this issue mostly comes from MMO. Another important issue discussed was the HYB documents used in the field and the lack of supervision and solution suggestions on the issue. Gürel stated that they, as the ministry, have started to collect more data from companies that register, and signaled that the ministry is on the subject.

The Third Session

The first speaker of the first session, which started on the second day under the moderation of Onur Ercan from EMO, was Dr. Ferhat Çelik from Blain Hydraulics. In his presentation titled “New Safety and Control Valve Systems for Hydraulic Lifts,” he provided the necessary information about when, where and how to use hydraulic control valves and then explained Blain Hydraulics’ new UCM, electronic and inverter control valve systems comparatively.

The second presentation of the day was delivered by Erdal Bingöl from Otis on Command and Control Systems. In his presentation, he gave detailed information about Destination Control Systems, Lifts Remote Monitoring and Control Systems and Otis’ smartphone applications.

The Fourth Session

After the coffee break, the first session started under the moderation of Kerem Şahin. Serdar Tavaslıoğlu started his presentation “Study on Safety Gear of Lift Car and Counterweight and a Calculation Proposal for the Sling Structure in Case of Seismic Movement” in accordance with the theme of the symposium by talking about the events that took place after the February 6 earthquake and those who lost their lives being stuck in the car. You can read the entire article of this presentation in the file subject of this issue.

The second presentation was delivered by Serkan Selamet from TK Asansör on the “EN 81-88 Earthquake Lift Design and Implementation Examples.” In his presentation, he explained what needs to be done according to EN 81-77 by giving an example of a 36-stop, 1600 kg, 2.5 m/s lift they installed in Izmir. He showed, with an earthquake video, why especially large buildings should be placed in separate blocks with dilatation and why lift wells should be positioned far from these points.

The last presentation was made by Prof. Dr. Erdem İmrak on “Damages in Hospital Lifts in Earthquake Zones.” İmrak provided detailed pictures of how the hospital buildings they visited during their fieldwork after the 2011 Van earthquake and the 2023 Kahramanmaraş earthquake were affected by the earthquake and why the lifts used for different purposes in hospitals were not operating after the earthquake.

The Fifth Session

The first presentation of the fifth session, which started under the moderation of Serdar Tavaslıoğlu, was delivered by Mehmet Ferit Pekeroğlu on Electrical Inspection Competence and Safety Management Principles in Lift Periodic Controls. Pekeroğlu said, “The reliability of electrical installations should be guaranteed as well as the general safety measures that should be installed as part of lift mechanical parts. Starting from the installation phase, the relevant electrical installations and components must be subjected to periodic inspections throughout the entire duration of use of the lift. Electrically safe work must be ensured in terms of machine safety and under the general occupational safety measures.”

Subsequently, Rıfat Özgür from Uludağ Asansör touched upon the subject of “Analysis of the Current Situation of Passenger Lifts and Research on Increasing the Security Level.” In his presentation, he made a comparison by examining the 74 articles of SNEL (Safety Norms for Existing Lifts) and the TSE inspection table for existing lifts.

The last presentation of the fifth session was delivered by Selda Tokoğlu Baloğlu from Astor Asansör. In her presentation titled “Lift Periodic Control Regulation: Problems Encountered in Implementing and Solution Suggestions,” she expressed her views on the Lift Regulation from the perspective of an operator rather than an engineer.

The Panel

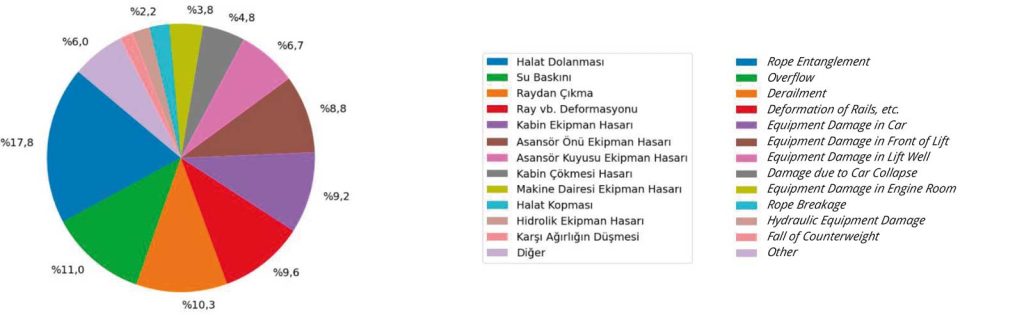

The panel, which was the most anticipated and most popular part of the symposium, was moderated by Bülent Çarşıbaşı. In the panel titled “Opinions on Lift Legislation,” İ. Menderes Büyüklü from the General Directorate of Industry of the Ministry of Industry and Technology took the floor first. Starting by thanking MMO and EMO for their efforts in the organization of the symposium, Büyüklü complained about the companies from Izmir for not setting up stands within the exhibition area while thanking the companies that came from other cities and setting up stands. In his presentation, he touched upon legislation, flow-chart for the current situation, statistics and problems. He stated that, while referring to the Communiqué on the Procedures and Principles Regarding Lift Design, it was said seven years ago that the lifts would not be installed according to the building, but the buildings would be designed according to the lifts. But nothing has changed after seven years. Büyüklü also shared current statistics about the industry. The industry had a current account deficit of US$25 million in 2016, but it is seen that it will have a current account surplus of approximately 500 million dollars in 2023. He also gave striking examples of incorrect data entry into ONTEK by approved inspection bodies (Table 2).

| YEAR | NUMBER OF LIFTS WENT UNDER THE FIRST CONTROL BEFORE REGISTRATION | FOREIGN TRADE DEFICIT/SURPLUS |

| 2016 | ………. | Minus 25 million $ |

| 2017 | 63.748 | Minus 65 million $ |

| 2018 | 59.439 | Plus 56 million $ |

| 2019 | 52.993 | Plus 94 million $ |

| 2020 | 41.414 | Plus 133 million $ |

| 2021 | 40.965 | Plus 145 million $ |

| 2022 | 48.104 | |

| 2023 | 44.921 | |

| 2024 | 34.109 (15.10.2024) |

Table 1: Türkiye’s Foreign Trade Data

| CTSP NO | CTSP DESCRIPTION | Exports in 2022 $ | Imports in 2022 $ |

| 842810 | Lifts | 390.977.000 | 416.557.000 |

| 843131 | Lift components and parts | 335.333.000 | 333.884.000 |

| Total | 726.310.000 | 750.441.000 | |

| CTSP NO | CTSP DESCRIPTION | Exports in 2022 $ | Imports in 2022 $ |

| 842810 | Lifts | 176.517.000 | 153.075.000 |

| 843131 | Lift components and parts | 63.352.000 | 86.786.000 |

| Total | 239.869.000 | 239.861.000 |

Table 1: Türkiye’s Foreign Trade Data

| A. Notified Body Activities | B. Inspection Body Activities | |||||||

| Conformity Assessment Method for Lifts | Document No | Conformity Assessment Method for Lift Safety Components | Document No | Red | Yellow | Blue | Green | Total |

| MODULE B | 617 | MODULE B | 46 | |||||

| MODULE D | 2 | MODULE C2 | 124 | |||||

| MODULE E | 1.088 | MODULE E | 12 | |||||

| LAST INSPECTION | 0 | |||||||

| MODULE G | 3.867 | 431 | 72 | 55 | 433 | 991 | ||

| MODULE H1 | 247 | 789 | 183 | 106 | 1627 | 2705 | ||

| Reports submitted to ONTEK between 01.01.2024-15.10.2024 | Reports submitted to ASTAK between 01.01.2024-15.10.2024 |

Table 2: Operations of Notified Bodies and Inspectıon Organizations

| NUMBER OF TYPE A INSPECTION ORGANIZATION (2023) | NUMBER OF THE RELEVANT ADMINISTRATION SIGNING PROTOCOL (2023) | NUMBER OF TECHNICAL MANAGER (2023) | NUMBER OF INSPECTION ENGINEER (2023) | NUMBER OF ANNUAL PERIODIC CONTROL (2023) | |

| MUNICIPALITY | SPECIAL PROVINCIAL ADMINISTRATION | ||||

| 36 | 1.122 (% 81) | 48 (% 94) | 188 | 1.138 | 798.372 |

Table 3: Data of Inspection Organizations and Annual Periodic Control

Speaking after Büyüklü, MMO Board Chairman Yunus Yener discussed the labor industry and presented a different perspective on the issue of qualified personnel. He said that as a service organization, more than 70% of MMO’s expenses are personnel expenses, and no other organization has such a high personnel expense. In his evaluation from the manufacturer’s perspective, Yener stated that, unlike other opinions, the establishment of Emlak Konut Asansör is positive according to his opinion.

TASFED Chairman Cem Bozdağ said:

“There is a complaint from the Ministry regarding the red labels, but I would like to state that the responsibility of lift, service and installation companies for some of these red labels does not belong to us. When our maintenance services examine the lift and say that the battery of the lift is dead and it needs to be changed, unfortunately, building owners do not listen to us very much. And they do not make any changes since they prefer not to make any expense on the lift. Then, what happens? Our service companies expect that type A inspection organizations will take care of the issue. They think that the type A inspection organization will say what the service company instructed but the building owner did not follow so that they will implement this and that practice. In other words, believe me, our service companies report most of the red labels to the building managers, but since there is money involved, the building managers cannot afford it.”

Bozdağ also said that this load is too heavy for the

installing companies in terms of weight, and he added: “When we look at the practice, they supply this load themselves during TSE inspections. Why shouldn’t other inspection organizations do this as well?”

Speaking on behalf of AYSAD, the new Chairman of the Board of Directors Fevzi Yıldırım looked at the situation from the bright side. He said that Türkiye had adapted to European standards in the lift and escalator industry much earlier than other industries. He conveyed this with an example by referring to the discussions in other industries of MAKFED, of which they are members. “In this period when the European Lift Association is discussing ISO 8100, we as Türkiye have a say and the power to contribute to the standard. As the components and real actors of the sector, we unfortunately cannot speak.” He also said that he worked as a contractor for a while and that it was the most comfortable period of his life since, unfortunately, the current system does not give the contractor any of the responsibilities it provides to the lift operator.

Onur Ercan who took the floor on behalf of EAYSAD said: “I would like to talk about a subject called the issues of the industry. As Mr. Menderes stated, we have come to a deadlock here when we should be speaking on more technological issues. What are the issues?” Stating that the staff members at inspection organizations are young and inexperienced, Ercan said that these young staff members also have a high risk of making mistakes.

The main issues that came to the fore during the question-and-answer section were the lack of qualified personnel, experienced engineers and technicians in the field.

Speaking about the lift accident in Aydın KYK dormitory, which was brought to the agenda by Zafer Güneş, Fevzi Yıldırım said that he was also a company that took part in that tender and that the price-oriented approach of the relevant parties ultimately led to this fatal accident. He said that no official who gave the job at that time considered the competence of the companies. He also said that the lift in Aydin was used a lot during the construction period, which had already worn out the existing lift before its registration.

Arzu Ballıkaya from AND Inspection organization said that they repeatedly applied to the Ministry regarding the low inspection fees, but they could not get any results. She stated that they expect a more proper adjustment from the Ministry next year, rather than a re-evaluation rate.

When Mehmet Cömert asked why TSE was not present in the panel, Moderator Bülent Çarşıbaşı stated that they were invited but did not come at their discretion.

Burak Demircan from MMO stated that there is a problem with disabled lifts in Türkiye and that this issue should be addressed immediately.

The Sixth Session

The first session of the symposium’s last day started under the moderation of İbrahim Özçakır.

The first presentation was delivered by Mohsen Seyyedi with the title of “Experimental Setup for Determining Fatigue Life of Lift Steel Wire Ropes.” In his presentation, Seyyedi stated that the repeated bending movement of steel wire ropes on the sheave causes the physical properties of the ropes to deteriorate over time and gave examples of some breaks that occurred as a result of these deterioration. Seyyedi said that a new steel wire rope fatigue testing machine design was carried out to determine the life of steel wire ropes and that the design consists of three sheaves, unlike the test mechanisms used in existing research in the literature. In this way, the necessary pre-tensioning was provided in the different types of ropes to be tested, and the required winding angle of the rope on the traction sheave and the rope-sheave contact length could also be controlled, he said. He also introduced a system that can detect damage on the ropes thanks to AI-powered image processing.

Subsequently, Nurullah Pireci from Brm Elektronik made a presentation titled “Digital Maintenance and Field Use of Devices Compliant to EN 81-28 Standard.” Starting with the definition of maintenance, Pireci explained how digital maintenance and digitalization will be integrated into the lift industry. He grouped the importance of digitalization in lifts under four headings: safety, efficiency and energy saving, remote monitoring and management and user experience.

The Seventh Session

For the first presentation in the session moderated by Barış Aydın, Prof. Dr. Erdem İmrak was on the stage for the second time with the title of “Lifts Subject to Seismic Conditions and Lessons Learned from Earthquakes: The Japanese Example.” İmrak delivered his presentation on the article of Umut Şahin, Eren Kalay and Serpil Kurt from the Lift Technologies Laboratory of the Istanbul Technical University. In his presentation, he explained the seismic damage to lifts and the changes made to Japan’s seismic design principles after the devastating earthquakes in 2011 Tohoku, 2016 Kumamoto and 2018 North Osaka. A caveat in his presentation was that, after the 2011 Tohoku earthquake in Japan, the Japanese inspected and reported the lifts in 370,000 buildings, while in our country, there was no official study on this subject and only some NGOs had the chance to inspect a very small number of lifts.

The second presentation was made by Eren Bahadır Aygün and Yusuf Kısa with the title of “Structural Analysis and Design of Lift Consoles Under Earthquake Load.” In their study, they examined the behavior and deformation of consoles commonly used in lift installations in the event of an earthquake and concluded that the console structure designed for use in seismic regions would not prevent the use of the lift after the earthquake and that it would be possible to remain in line with the guide rail within the limits of ride comfort with the resulting deflection value.

The last presentation of the session was delivered by Bülent Çarşıbaşı from EMO with the title “Antalya Tünektepe Cable Car Accident, Cable Equipment Carrying People” regarding the cable car accident that occurred in Antalya on April 12, 2024. He said that with the circular issued in 2009, the licensing authority for cable transport systems was given to MMO and EMO, and EMO Izmir and MMO Bursa branches were selected as authorized. He said that although there are more than 300 facilities in our country, only 72 applications have been received so far and 48 of these facilities have been able to receive a license. The determination regarding the accident in Tünektepe is as follows:

“On April 12, 2024, at around 17:20, two pulley sets out of 10 pulleys in the direction of rotation and 10 pulleys in the direction of travel on pole number five got stuck, and the rope first tore the rubber of the pulley and then the pulley broke, causing the system to stop automatically. However, this situation was not noticed and the system was restarted, as a result of the force created by the rope coming off the pulleys, the bolts in the middle of the pole were damaged, and as can be seen from the picture, the upper 9.5 m part of the pole separated and fell approximately 15 m down the service road. As a result of the rope coming off the pulley, car No. 28 hit the pole and was torn apart, leading seven out of people to be injured and one person to die.

The Eighth Session

After lunch, the last session of the symposium was initiated under the moderation of Mustafa Akışın regarding the escalators. Battal Murat Öztürk, who took the floor first, delivered a presentation titled “On-Site Revision in Escalators/Conveyor Belts.” Stating that on-site modernization is quite difficult today since there are 50 to 60 different manufacturing types of escalators, Öztürk explained the manufacturing stages of on-site revision process.

The last presentation of the symposium was delivered by Koray Kalay on the “Handrails of Escalators.” Kalay said that the selection of handrails should meet the necessary safety, quality and hygiene requirements, and provided information on maintenance and durability conditions.

After reading the symposium’s final declaration, a group photo was taken with all the delegates in the Hall.

Get more of Elevator World. Sign up for our free e-newsletter.