Blue Cross and Blue Shield Building, 300 East Randolph, Chicago, Illinois

Jan 1, 2012

Category 1: Elevators, New Construction

submitted by Joshua Bietsch, Mitsubishi Electric & Electronics USA, Inc.

photos by American Institute of Architects, Brian Fitz Photography, D. Swanson and J. Steinkamp

Project Overview

The Health Care Service Corp. (HCSC) headquarters housing Blue Cross and Blue Shield of Illinois at 300 East Randolph Street in Chicago opened in 1997 with 23 elevators and eight escalators installed by Mitsubishi Electric & Electronics USA Inc.’s Elevator and Escalator division. The 33-story, 440-ft.-tall building was designed as a two-phase, vertically expandable office tower, capable of reaching a height of 800 ft. via a vertical completion project (VCP). The VCP, which began in 2006, raised the total number of stories to 57, adding more than 920,000 sq. ft. to the existing 1.43-million sq. ft.

The project team had to construct the entire VCP over a live lobby in a fully occupied building without disrupting daily operations or impacting the safety of the building’s tenants. As a result of initial design planning, there is no visible distinction between the older phase-one and new phase-two portions of the building. Other challenges included the logistics of staging, handling and installing the required structural steel, mechanical equipment, interior materials and elevator components through and above the active lobby.

Transportation System and Installation

During phase one, vertical shafts for future elevators were created, but without unutilized voids that would compromise building efficiency. The solution was to build an atrium comprised of several 40-ft. by 30-ft. open structural bays. Two of the bays were used for a pair of eight-car passenger-elevator banks in phase one; two others were set aside for two additional eight-car banks that would be installed during phase two.

All rail support structures, rail brackets and elevator guide rails would be installed after hours. The original building design provided no landings for the 16 new passenger traction elevators or access to hoistways between the lobby and top occupied floor. More than half the rail brackets and nearly 2,800 jumbo rails weighing 22 lb./ft. had to be installed and aligned in one 430-ft. “jump” for each passenger unit until the first landing was reached.

In addition to the 16 passenger elevators, three new service elevators were to replace the existing service cars in hoistways constructed directly above the existing equipment. Mitsubishi Electric would extend the main and counterweight guide rails upward from the original topmost service-car rails, around the existing overhead sheaves and support steel carrying the live service elevators, then up into the phase-two portion of the building. An additional challenge was meeting rail accuracy throughout the entire 800-ft. hoistway in what were actually two separate structures.

Because the HCSC building is in the heart of downtown Chicago, deliveries and staging of vast amounts of equipment became problematic, and moving just enough material into the lobbies for each night’s installation needs would have significantly delayed construction. Specifically, four elevator units had to be built simultaneously in each of the two passenger-car groups for Mitsubishi Electric to meet its contractual commitments. The volume of materials needed to support so many elevators being installed at once precluded moving material through the lobby on a night-by-night basis as planned.

Mitsubishi Electric proposed an off-site storage facility where containers from Japan could be offloaded and contents staged in a weather-resistant warehouse. Getting large amounts of mechanical equipment, structural steel and more than 1 mi. of rails from the subterranean garage to the top of the building was another hurdle. Mitsubishi Electric recommended the development team cut large openings through the pit floors between each passenger bank providing access to a large parking area directly below the elevators. A trucking firm was contracted to deliver materials on the service street below the building on an as-needed basis.

Virtually all mechanical components for the passenger cars were delivered through the parking garage. Materials were offloaded on the lower-level service street using a job-specific fork truck, transferred to a custom truck-and-trailer package, then carted into the parking garage. Inside the parking structure, a large shanty was constructed to enclose the pit-floor access holes, allowing unrestricted access to deliver, stage and hoist materials in sufficient volume to support the more than 50 on-site elevator constructors.

Sixteen new false cars with high-speed hoist motors and new two-speed rail hoist machines kept Mitsubishi Electric ahead of schedule. Mechanics in charge of each group of passenger cars led crews to install guide rails. More than 5,200 main and counterweight guide rails were accurately installed, despite the initial 430-ft. jump to the first target.

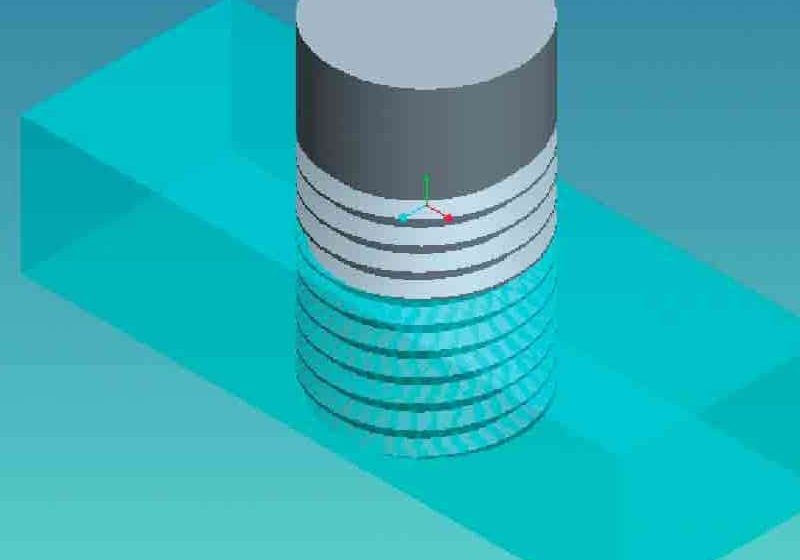

Concurrent with rail installation, 19 Mitsubishi Electric AC Permanent-Magnet gearless machines (16 passenger, three service), secondary sheaves and machine bases were preassembled at the off-site storage facility to be “flown up” with their respective control cabinets. This facilitated delivery at the appropriate point in the structural-steel erection of the VCP.

Replacing the three original service cars from phase one proved to be almost as complex as the installation of the 16 new passenger cars. Three service cars supported the day-to-day operation of the existing building’s 33 freight landings and handled the large volume of construction materials necessary to expand the building to its new height. No more than 91 days of total downtime, from its initial decommissioning to return to service, was allowed for each unit. What’s more, only 460 ft. of existing rails — from the receiving level to the top of the phase-one structure — were to be retained; all other equipment had to be replaced. Reactions incurred by the increase in elevation meant the original car and counterweight frames also had to be replaced.

Mitsubishi Electric installed new service car rails, extending from the existing structure to the topmost floor served, then built all subassemblies — such as the complete car, counterweight assembly and overhead-machine assembly — in the phase-two hoistways above the operating units. Car and counterweight assemblies were suspended on rigging in the new hoistways in advance of decommissioning a unit, and new entrance assemblies and hoistway components were installed using false cars. When the first replacement unit was fully prepared, the car below it was shut off and the 91-day clock started.

Using a custom-ordered, 20,000-lb., 800-ft. single-line pull hoist, Mitsubishi Electric was able to raise all the old equipment, including the complete cab assembly, from the phase-one shaft into the phase-two area for demolition and removal. Following, the new components were lowered and secured in proper position for cabling. When the remaining hoistway work and adjustment was completed, the new service unit was ready for inspection.

Embarking on a project of this scale required close cooperation from Mitsubishi Electric’s engineers and technical staff in both the U.S. and Japan, as well as the confidence of its partners. Each challenge presented an opportunity to create a new way to meet it. Though Mitsubishi Electric and the building team did not have a similar project to use as a touchstone — this was the world’s first building with 33 occupied stories to add an additional 24 stories while remaining fully operational — ultimately, 4,000 employees at 300 East Randolph went about their daily business with little notice of the work. The project was completed in December 2010.

Specifications

- Building height: 800 ft. in 57 stories

- Total office space: 2.35 million sq. ft.

- The Blue Cross/Blue Shield headquarters occupies 384,000 sq. ft., with 365,000 sq. ft. used by other tenants.

- The building also includes a 900-seat cafeteria, a 31,000-sq.-ft. conference and training facility, and a 22,000-sq.-ft. conference center.

Credits

- Architect: Goettsch Partners, Inc.

- Building owner, developer: Health Care Service Corp. of Illinois

- Consultant: Jenkins and Huntington, Inc.

- Contractor: Walsh Construction

- Development manager: The John Buck Co.

- Equipment manufacturer and component supplier:

Mitsubishi Electric Corporation

Get more of Elevator World. Sign up for our free e-newsletter.