“Green” Escalators: Calculating, Quantifying and Reporting

Dec 5, 2022

How to credibly claim and compare the environmental performance of escalators and moving walks

by Sascha Iqbal

Strictly speaking, there is nothing such as a “green“ escalator, unless it has a green-colored handrail or your escalator is decorated with some fancy green-colored balustrade or lateral cladding panels.

Evidently, however, each product and activity has an impact on the environment, which is bigger or smaller when compared with a reference or benchmark. Thus, the question is more about how much “greener” the overall environmental performance of one escalator is (i.e., how much lower its potential environmental impacts are) when compared to a competitor’s.

LCAs: Calculating and Quantifying “Green”

The scientific method most recognized globally to measure “green” is using a life cycle assessment (LCA). Standardized by ISO 14040[1] and ISO 14044,[2] an LCA allows for a quantified estimate of the environmental impacts of each lifecycle stage of a product or service.

Performing an LCA for a rather complex product such as an escalator or moving walk system and its underlying supply chain is a laborious task, requiring about six to 12 months of work from a core team of one to two persons skilled in LCA, resulting in lengthy, technical reports with LCA results in greater-than-necessary detail for the common understanding of non-LCA-experts.

Not only the LCA project core team, but also numerous departments (R&D, purchasing, marketing, field offices, logistics, fleet managers, etc.), manufacturing locations and suppliers are involved. These participants also need to be trained in LCA, briefed about the purpose of the LCA project, informed about what data is needed and advised how this data can practically be collected.

Thus, performing a full LCA from “cradle-to-grave” requires a considerable investment of time, skills and financial resources that companies may initially feel reluctant to commit to, unless LCA’s clear value-add becomes obvious (e.g., when contracts are lost to competitors able to provide more transparent and quantifiable environmental performance-related information).

EPDs: Reporting “Green”

Within the context of “green” building rating and certification schemes, such as Leadership in Energy and Environmental Design (LEED), Building Research Establishment Environmental Assessment Method (BREEAM®), the Chinese Green Building Evaluation Label (3-Star), the German Sustainable Building Council (DGNB System), the French High Environmental Quality Standard (HQE™) or Green Star founded by the Green Building Council of Australia, so-called “environmental product declarations” (EPD) have gained importance due to being accepted for (or contributing to) achieving credits.

Of particular note are LCAs or EPDs accepted for achieving or contributing to the achievement of up to two points of the EPD materials and resources (MR) credit under LEED v4.1 (2022).[3]

EPDs are standardized (in general) according to ISO 14025,[4] where they are officially named “Type III Environmental Declarations,” and for building products (in particular) according to ISO 21930[5] and CEN 15804[6 and 7] being the currently most evolved, widespread and accepted EPD standards related to building products.

As opposed to full LCA reports, EPDs do summarize LCA results in a more concise, brochure-like form. Quite a few escalator manufacturers have, thus, already published EPDs or EPD-like documents for their products[8-11] according to ISO 14025[4] and CEN 15804.[6 and 7]

To genuinely allow and support architects, builders, planners, public bodies or contractors to make informed “green” purchasing decisions, EPDs should be comparable, i.e., LCA results must have been calculated according to the same rules and system boundaries. This is where so-called product category rules (PCR) come in.

PCRs: Calculation Rules for “Green”

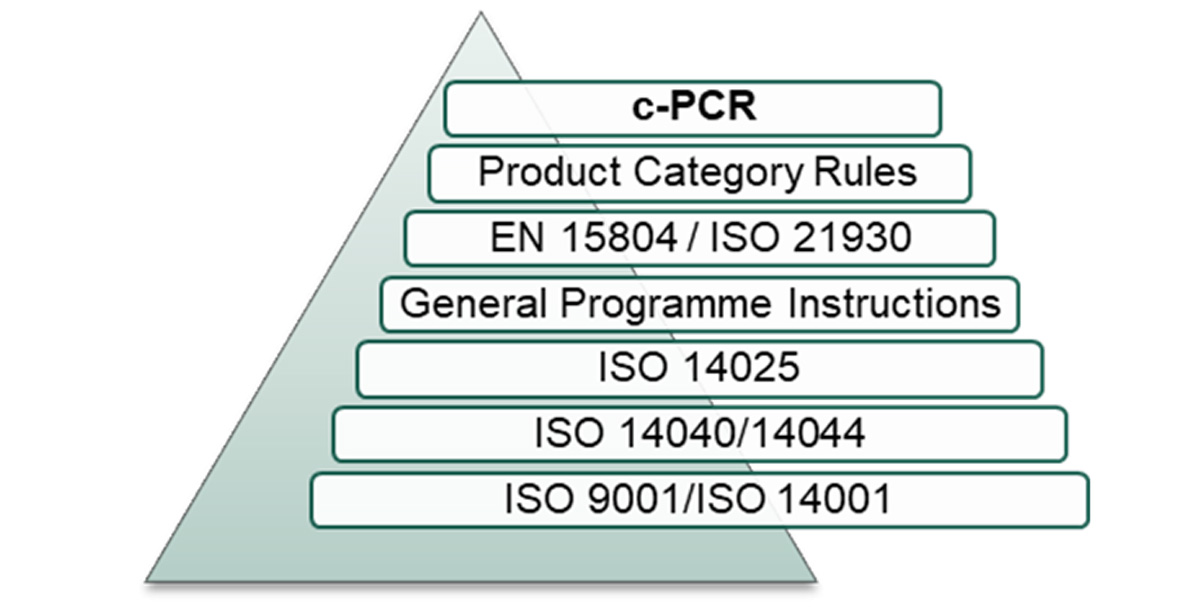

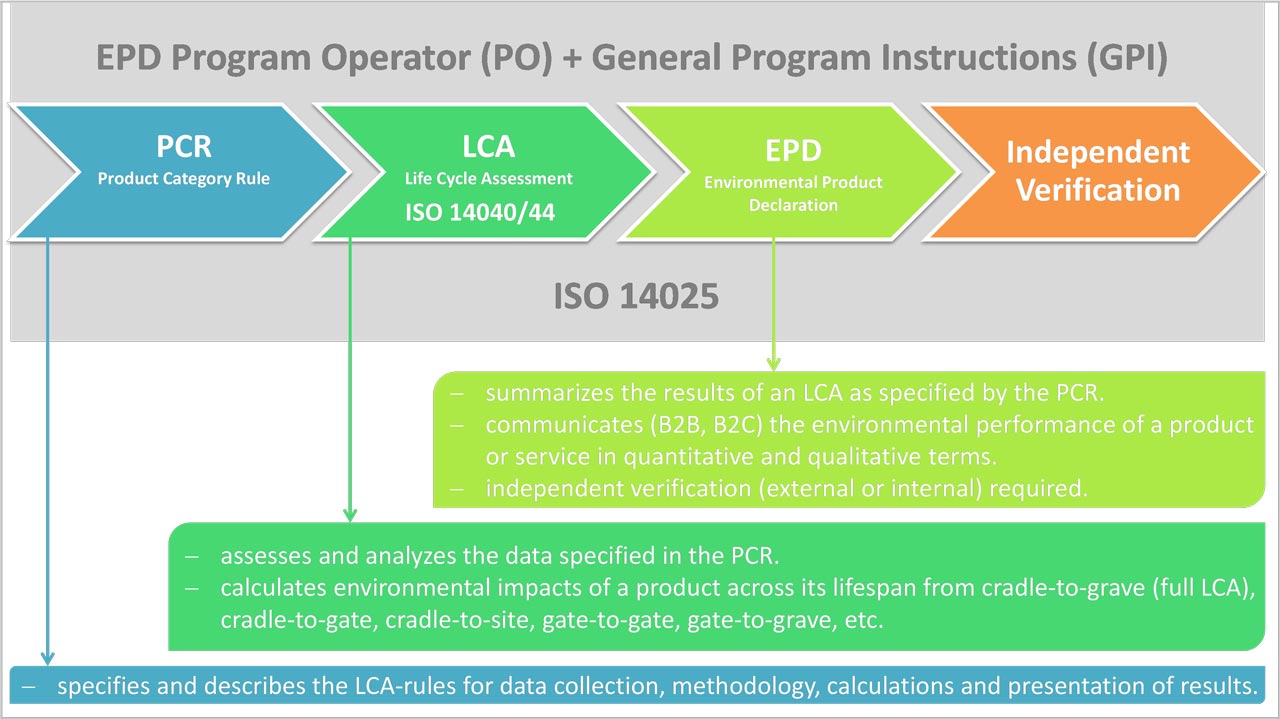

PCRs define the calculation rules and system boundaries (which life cycle stages, information modules and processes to in-/exclude from the LCA study) for the underlying LCA, as well as format and content for reporting in an EPD. The existence of a PCR is a prerequisite to elaborate on an EPD, in order to be in conformity with ISO 14025.[4] The current most widely used core PCRs for building products are CEN 15804+A1[6] and its successor, CEN 15804+A2.[7]

First Escalator PCR Development

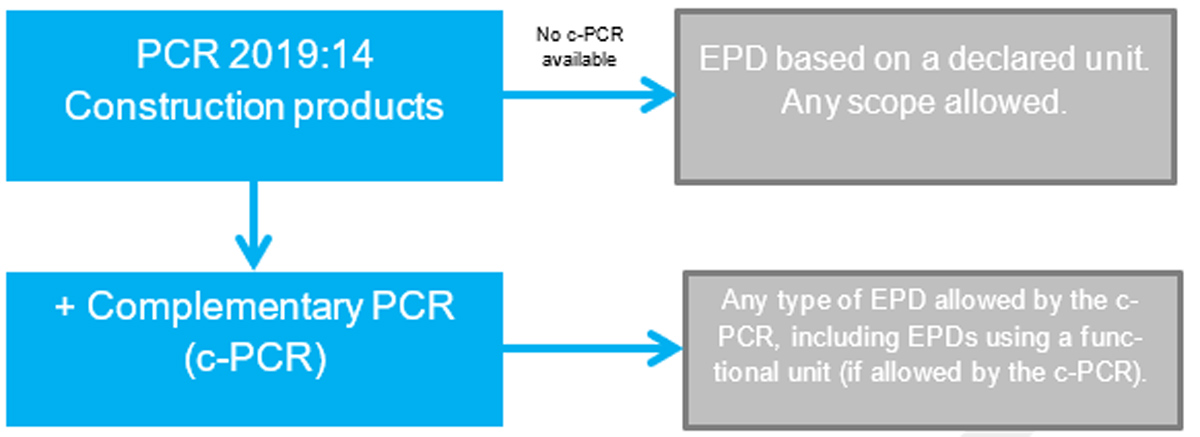

Development of the first complementary PCR (c-PCR) for escalators and moving walks was initiated on December 29, 2021, under the umbrella of The International EPD® System (environdec.com) acting as so-called EPD program operator (PO, see below), as defined by ISO 14025.[4] “Complementary” means complementary to the PO’s PCR 2019:14[12] for construction products, which is based on the core PCR for building products CEN 15804[7] (Figure 1). The c-PCR currently under development is based on the requirements of the PO’s so-called general program instructions (GPI),[13] ISO 14025[4] and CEN 15804[7] including a mandatory independent third-party verification of the EPD (Figures 2 and 3).

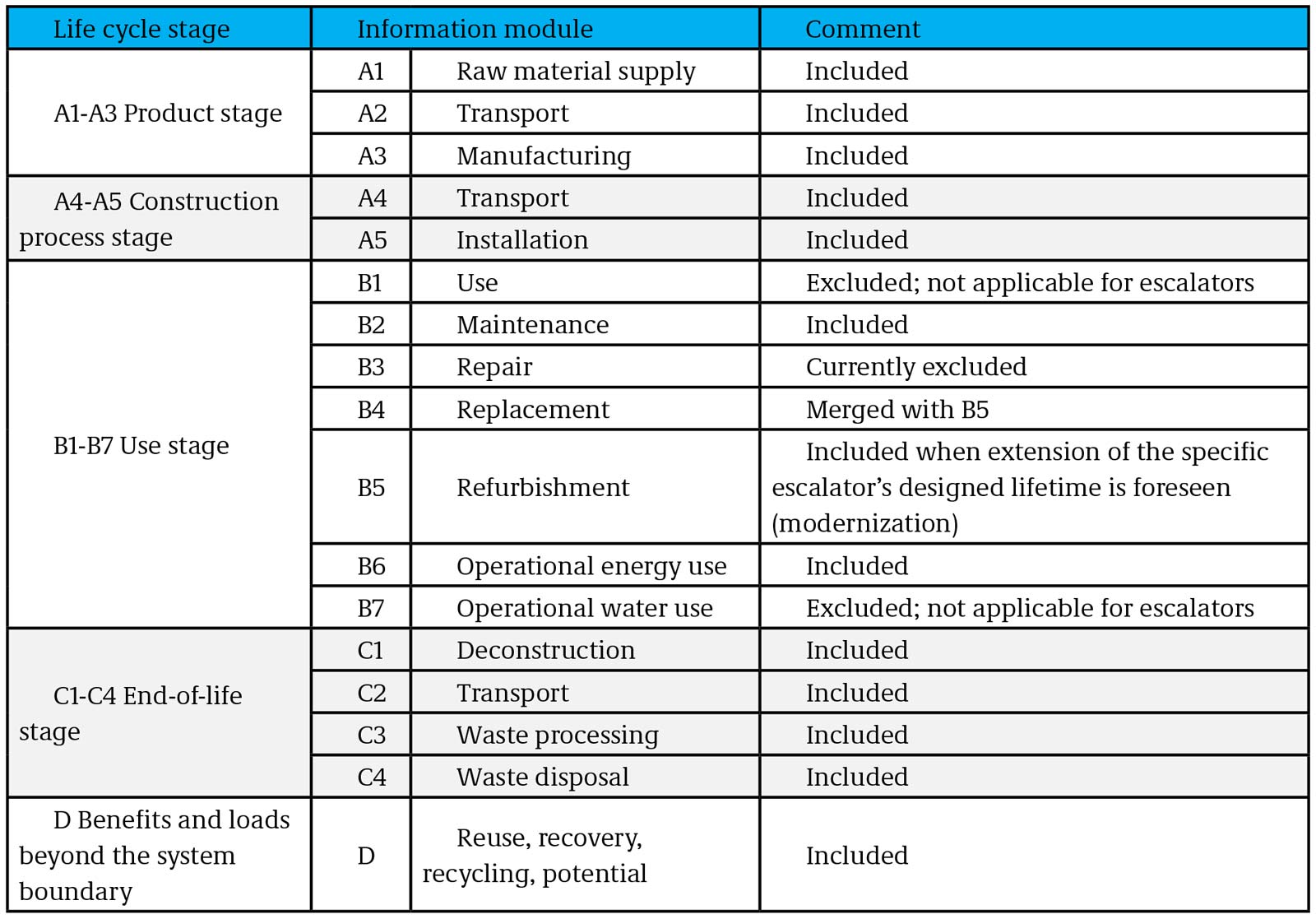

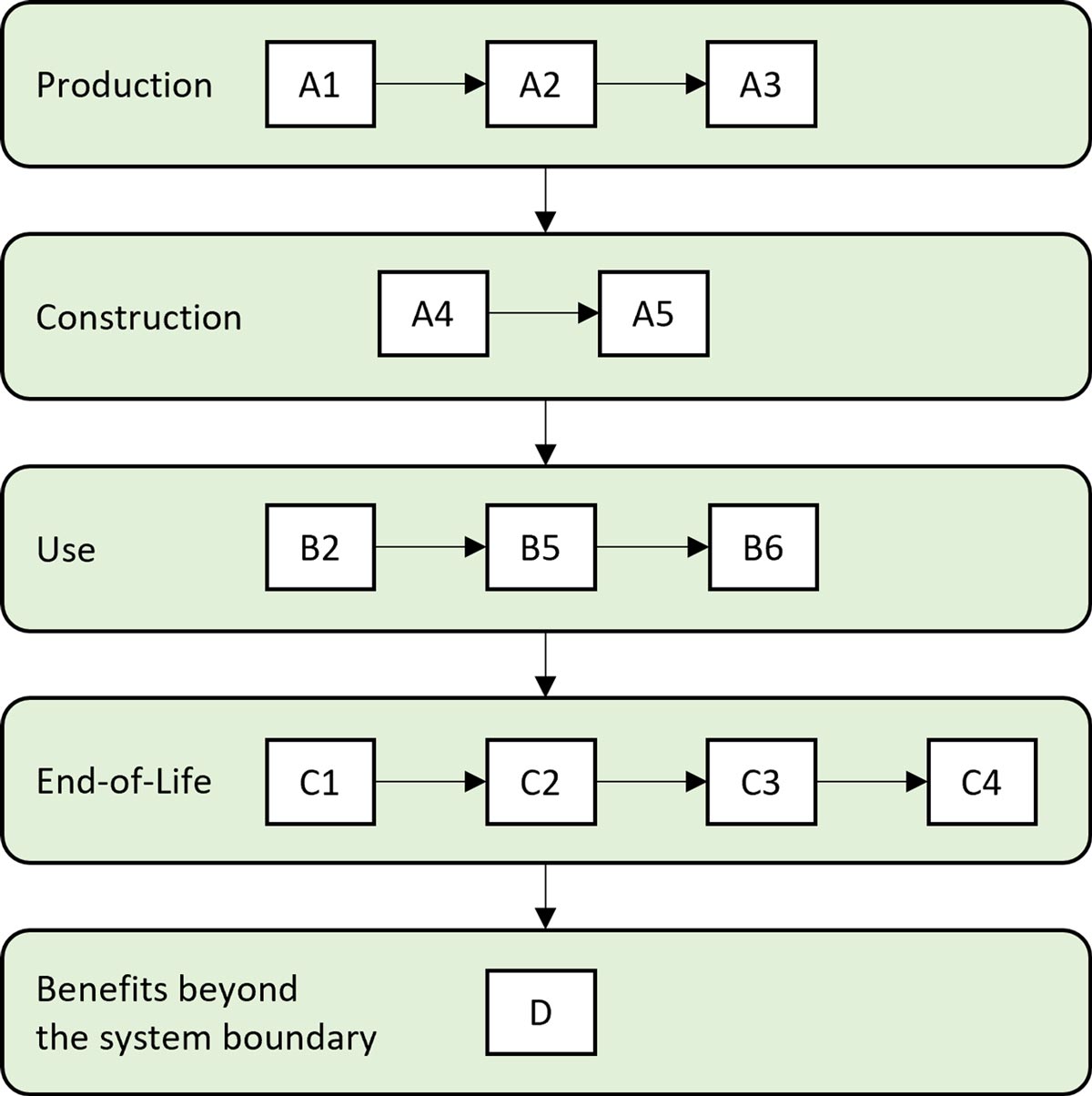

The draft escalator life cycle model (Figure 4) in the c-PCR made available for the first open stakeholder consultation proposed to in-/exclude the following life cycle stages and information modules as per CEN 15804:[6 and 7]

PO: Administrative Framework for “Green”

A PO basically acts as administrative body of an EPD program; prepares, maintains and communicates its GPIs; maintains publicly available lists and records of PCR documents and EPDs; and is required to establish a transparent procedure for PCR review through an open stakeholder consultation (OSC). [4]

Draft Escalator c-PCR Consultation

The first OSC of the draft escalator c-PCR was launched on July 5, 2022, by actively inviting, at least, more than eight dozen companies, industry associations, industry internet groups and individuals from around the globe. It ended on October 16, 2022.

A second OSC was scheduled for launch in November 2022, where comments could be submitted by using the template for commenting on the draft PCR, available for download from The International EPD® System’s website (environdec.com/product-category-rules-pcr/get-involved-in-pcr-development#pcrsinopenconsultation), where the latest draft escalator c-PCR was made available for download.

The main challenges and issues encountered during the PCR development process and addressed during the first OSC included the following:

- Maintain balance of interests between industry representatives (escalator companies and associations), academia, governmental/non-governmental institutions and independent LCA experts within the PCR Committee and stakeholder groups.

- Parameters (allowed/not allowed to be modified, e.g., in case of a customized estimation of energy consumption for a specific escalator) and (default) electricity mix used for energy demand (kWh per year and per reference service life) and related environmental impact calculations in module B6 according to ISO 25745-3, [14] and comparability of LCA results between EPDs resulting from the same.

- In-/exclusion of module B3 (repair, corrective maintenance) with respect to the cut-off rules defined in CEN 15804.[7]

- Delineation between modules B4 (replacement) and B5 (refurbishment), definition of the term “modernization,” and reuse of components.

- Declaration of pre- and post-consumer recycled content, as per guidance given in ISO 10421,[15] particularly for the various steel and aluminum alloys present in large quantities in escalators and moving walks.

- Declaration of hazardous substances.

- Direct emissions of volatile organic compounds (VOCs) to air from the use of solvents, such as e.g., white spirit, kerosene, “coal oil,” etc., during the use stage.

- Guidelines for waste disposal of escalator subsystems, components and parts during the use stage and at end-of-life.

- Selection and use of generic background life cycle inventory (LCI) databases also with respect to information exchange between escalator manufacturers and component suppliers.

Facilitating Informed “Green” Purchasing Decisions

In practice, escalator EPDs and the respective LCA results contained in them have so far (if using PCR 2019:14 respectively CEN 15804[6 and 7] directly to develop an EPD and not the draft escalator c-PCR made available for the first OSC) been very difficult or almost impossible to compare due to differences in functional units, calculation rules, default values, assumptions, background life cycle inventory (LCI) data, system boundaries or allocation and cut-off rules applied.

The “functional unit” (or FU for short) is defined as a quantified performance of the product for use as a reference unit in an environmental declaration of the life cycle of a product. Its primary purpose is to provide a reference by which input and output flows (material, energy, waste, emissions, etc.) of the escalator LCA results, and any other information is normalized to produce data expressed on a common basis.[6, 7 and 13]

In the draft escalator c-PCR made available for the first OSC, “the function of an escalator is defined as the transportation of passengers over an inclined (or horizontal) trajectory. Thus, the FU is defined as the transportation of one passenger over one m, i.e., passenger-metre [pm] over an inclined (or horizontal) trajectory”.

According to the draft escalator c-PCR made available for the first OSC, “LCA results shall be presented per FU, i.e., per 1 [pm]. To do so, first the total amount of [pm] (called also “Transportation value”, TV for short) shall be calculated, followed by division of the respective inputs and outputs by the TV to obtain the LCA results per FU.”

The TV shall be calculated according to the following formula and parameters: TV=L*N*dOP*RSL

where:

- L – length of the escalator/moving walk in [m], based on the specification of the product; when the system under study is inclined (for escalators and inclined moving walks), the length shall be calculated as the rise (H) divided by a tangent of the angle of inclination (α), i.e., L=H/tan(α)

- N – average number of passengers transported per day as per ISO 25745-3,[14] Table A.1

- dOP – number of operating days per year, based on the specification of the product

- RSL – reference service life in years, based on the specification of the product

Thanks to the introduction of a uniform FU and the introduction of the concept of TV by the new c-PCR, escalator EPDs should now be more easily comparable, supporting one of the key objectives of ISO 14025[4], stated in its clause 4b), namely: “[…] to assist purchasers and users to make informed comparisons between products; […].”

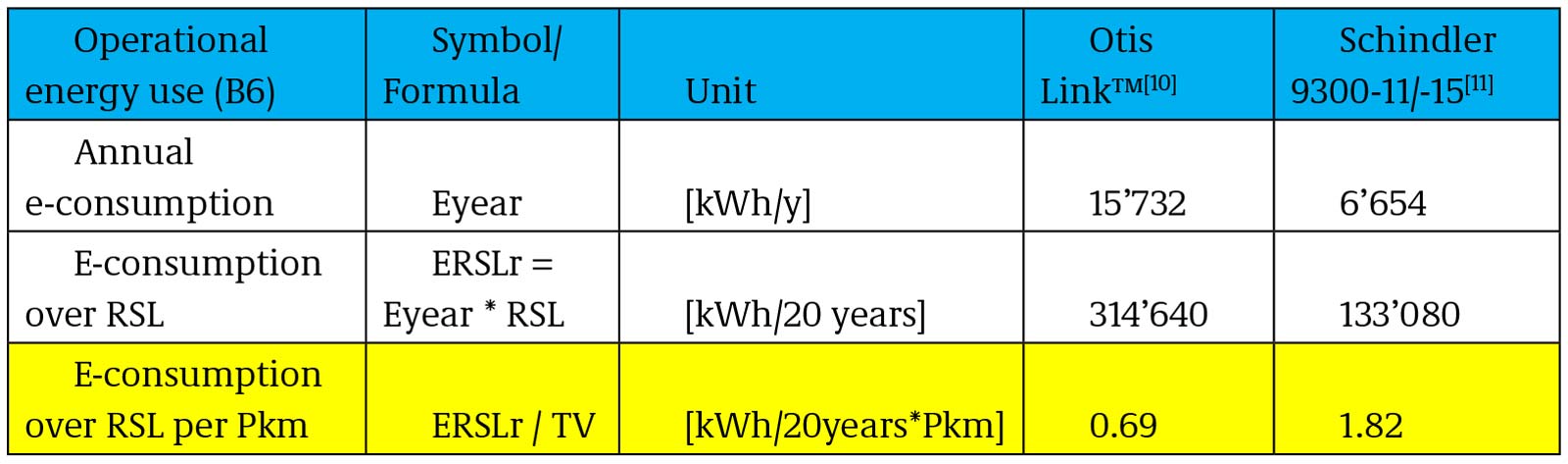

This suggests attempting to compare existing EPDs, which have been developed using CEN 15804[6 and 7] directly, i.e., before the existence of the draft escalator c-PCR made available for the first OSC, such as e.g., the comparison of the EPDs for the OTIS Link™ Escalator[10] and the Schindler Escalator 9300-11/-15,[11] which both declare an identical typical application (shops/shopping centers), reference service life (20 years), rise (4.5 m) and inclination (30º) and, therefore, an identical calculated length (7.8 m) as outlined in table 2 below, showing how the TV value could be calculated, expressed in Person-kilometers [Pkm] (instead of Person-meters [Pm]):

Although different number of passengers per day (N), operating days per year (dop), background LCI databases and electricity mixes of different geographic regions (except for China) have been applied, the lifetime electrical power consumption in module B6 can hence be normalized by the TV, as per below table:

The about 2.6x times higher specific lifetime e-consumption per Pkm of the Schindler product can likely be explained by the difference in operation mode (sleep mode vs. continuous operation), although more detailed information about the operation mode and energy calculations according to ISO 25745-3[14] was not available to the author respectively declared in the Otis EPD.[10]

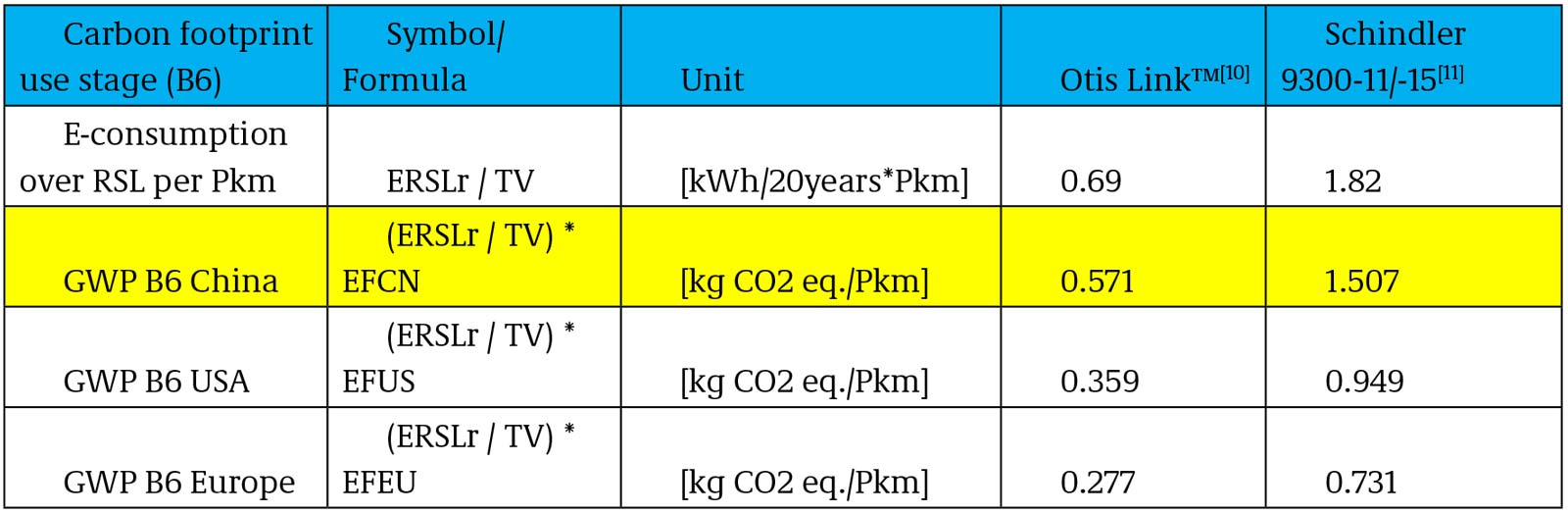

Geographically, harmonized LCA result indicators for module B6, such as, e.g., the global warming potential (GWP), more commonly known as carbon footprint (CFP), can now be obtained by multiplying the lifetime electricity consumption per Pkm with common emissions factors (EF), such as e.g., declared in the Otis Link™ EPD[10] for China (0.826 kg CO2 eq./kWh), the U.S. (0.520 kg CO2 eq./kWh) and Europe (0.401 kg CO2 eq./kWh) as follows:

It should be noted that, for the purpose of comparison, ISO 14025[4] requires consideration of all life cycle stages and respectively states, that “Type III environmental declarations not based on an LCA covering all life cycle stages, or based on different PCR, are examples of declarations that have limited comparability.” If trying to do so for China as a geographical region, and by excluding module B3 from the system boundary of the Schindler EPD[11] and taking the GWP result of Table 4 for module B6 for the Schindler product, the following estimated results would be obtained:

Table 5 suggests an almost 3x times higher estimated total carbon footprint (CFP) per Pkm of the Schindler product in comparison with the Otis product, despite the fact that the Schindler product is about 1 mT less in weight (Table 2), and the GWP-total indicator according to CEN 15804+A2[7] includes biogenic carbon (GWP-biogenic) and carbon from GWP-land use and land use change (GWP-luluc), which are not considered in the GWP indicator of CEN 15804+A1.[6] The reasons for this significantly higher CFP are difficult to explain without further detailed analysis of the underlying LCA reports to which purchasers and EPD users normally do not have access, and may probably also be rooted in the different background LCI databases applied in [10] and [11] (Table 2: GaBi LCI database[16] respectively Ecoinvent LCI database[17]) and differences in operation modes (sleep mode vs. continuous operation).

In any case, the above example illustrates that comparing EPDs elaborated according to CEN 15804[6 and 7] is not trivial without having access to the underlying LCA reports, in particular to details about operation mode and parameter values applied, as well as assumptions made for the energy calculation of module B6 according to ISO 25745-3.[14] An easier and more straight-forward comparison satisfying ISO 14025’s[4] key objective of enabling the comparison EPDs for informed purchasing decision making by applying the new escalator c-PCR that is in the process of being developed for the elaboration of escalator EPDs remains yet to be demonstrated.

References

[1] ISO 14040: 2006 Environmental management — Life cycle assessment — Principles and framework

[2] ISO 40044: 2006 Environmental management — Life cycle assessment — Requirements and guidelines

[3] LEED v4 Building product disclosure and optimization – environmental product declarations (usgbc.org/node/2616376?return=/credits/new-construction/v47material-%26-resources accessed October 17, 2022)

[4] ISO 14025: 2006 Environmental labels and declarations — Type III environmental declarations — Principles and procedures

[5] ISO 21930: 2017 Sustainability in building construction — Environmental declaration of building products

[6] CEN 15804: 2012+A1:2013 Sustainability of construction works – Environmental product declarations – Core rules for the product category of construction products

[7] CEN EN 15804:2012+A2:2019/AC:2021 Sustainability of construction works – Environmental product declarations – Core rules for the product category of construction products

[8] EPD KONE TravelMaster™ 110 and 110T (environdec.com/library/epd6533 and environdec.com/library/epd6370 both accessed October 17, 2022)

[9] EPD TransitMaster™ 140 and 140T (https://cer.rts.fi/wp-content/uploads/rts_84_20-kone_transitmaster_140_epd_22-03.pdf and environdec.com/library/epd5304, both accessed October 17, 2022)

[10] EPD Otis LINK™ Escalator (environdec.com/library/epd5405 accessed October 17, 2022)

[11] ”EPD-like” Environmental Fact Sheet (EFS) Escalator Schindler 9300-11 / -15 (Version 1.0, June 2018, Schindler Fahrtreppen International GmbH, Vienna, Austria prepared by IQ Consult GmbH Basle, Switzerland)

[12] PCR 2019:14 Construction products of the International EPD® System (Version 1.2.3, environdec.com)

[13] General Programme Instructions (GPI) of the International EPD® System (Version 4.0 dated 2021-03-29. environdec.com)

[14] ISO 25745-3:2015 Energy performance of lifts, escalators and moving walks – Part 3: Energy calculation and classification of escalators and moving walks

[15] ISO 14021:2016 Environmental labels and declarations

[16] GaBi LCI database (sphera.com/product-sustainability-gabi-data-search/)

[17] Ecoinvent LCI database (ecoinvent.org)

Also read: “Green” Elevators: Calculating, Quantifying and Reporting

Get more of Elevator World. Sign up for our free e-newsletter.