Car Top Balustrades and Work at Height

May 29, 2024

Are the protective measures suitable for the work to be performed?

A With the focus of this issue upon safety, a look at EN 81-20 provisions for lift car top balustrades and work at height (a key industry safety requirement) in terms of wider U.K. health and safety regulation may be of interest, particularly in relation to indications of a wider industry lack of understanding, and some misunderstanding, of the requirements.

The current requirements originated in the Lifts Directive 1995 and EN 81-1: 1998, which was the first occasion on which car top balustrades appeared as a specific U.K. safety requirement.

The effect was such that previous U.K. recommendations and working practices were rendered obsolete by a legal duty to provide a safe product compliant with the intent of the Directive. The introduction of the car top balustrade (or other equivalent protection) raised the state-of-the-art such that the balustrade became the predominant safety provision in respect of work at height from lift car tops for new and existing lifts.

A query sometimes arises in relation to the disparities between EN 81 provisions and more widely applied U.K. regulation, and particularly that of the Work at Height Regulations 2005 (WaH Regulations) and the design of balustrades and barriers.

Schedule 2 to the WaH Regulations provides for a minimum height of 950 mm for the top guard rail of any balustrade or barrier and for a maximum vertical gap of 470 mm between any intermediate rail and other means of protection. However, it should be noted that these provisions relate only to work at height that is undertaken in relation to “Construction Work.”

Otherwise, the Regulation provides that the means of protection shall:

- (a) be of sufficient dimensions, of sufficient strength and rigidity for the purposes for which they are being used and otherwise suitable;

- (b) be so placed, secured and used as to ensure, so far as is reasonably practicable, that they do not become accidentally displaced; and

- (c) be so placed as to prevent, so far as is practicable, the fall of any person, or of any material or object, from any place of work.

So, the regulatory position is that the minimum design requirement for balustrades and guards for Construction Work is prescribed, whilst the wider provision follows a risk-based approach relating to an assessment of the work to be undertaken against a measure of practicability, albeit that the use of the terms “practicable” (as opposed to “reasonably practicable”) and “prevent” in (c) are clearly indicative of a raised level of duty.

The prescriptive provisions for Construction Work are no longer restated in other legislation, such as the Construction (Design and Management) Regulations 2015 (CDM), with work at height now consolidated in the WaH Regulations, albeit that the technical and dimensional provisions continue to reflect their origins in earlier construction-related regulation.

I recall an occasion in which a Health and Safety Executive (HSE) inspector stopped work on a lift installation due to the car top having a 700 mm high balustrade, as was at the time permitted under EN 81-1: 1998. The inspector was correct in that the lift was, at the time, under construction and incomplete, such that the provisions of the Lifts Regulations did not apply (the Declaration of Conformity had not yet been issued), and the provisions of Schedule 2 of the WaH Regulations applied, requiring a minimum balustrade height of 950 mm. A temporary balustrade compliant with Schedule 2 provisions was installed, and the lift works proceeded. Once complete, the 700 mm high balustrade was reinstated and the Declaration of Conformity was issued.

The key point to take from this is that all work at height must be risk assessed to ensure that the protective measures are suitable for the work to be performed, and in the case of Construction Work, that these meet the prescribed minimum dimensional and other provisions, which, it must be remembered, are the minimum requirement. More robust measures may be required dependent upon the nature of the work to be undertaken.

EN 81-20 provides for car top balustrades in cases in which the horizontal distance between the outer edge of the car top and the wall of the shaft exceeds 300 mm.

The height of the balustrade is a minimum of 700 mm for a horizontal distance of between 300 mm and 500 mm (reduced from the 850 mm permitted under EN 81-1) and increasing to a minimum of 1100 mm for a horizontal distance in excess of 500 mm. In each case, the horizontal distance is measured from the inner edge of the balustrade handrail and the wall of the well.

Balustrades must incorporate a handrail and an intermediate bar positioned at half the height of the balustrade. The balustrade must be located within 150 mm of the edge of the car roof and with a minimum clearance of 100 mm between the outside of the handrail and any part in the well.

EN 81-20 introduced an additional requirement above that of EN 81-1 in that the balustrade must be constructed to resist a horizontal force of 1000 N applied at any point at the top of the balustrade and be such that elastic deformation should not exceed 50 mm. Too often the balustrades installed under EN 81-1 were of flimsy design and construction and, in my view, inadequate in terms of meeting the purpose of preventing falls from the car top.

A car top perimeter toe-board of minimum height 100 mm is required in all cases.

One may question the difference between EN 81-20 requirements and those of U.K. safety legislation. The answer lies in the fact that lifts are “products” within the Lifts Directive formulated under European Union Product and Competition Regulation, whereas the U.K. legislation in question, the WaH Regulations 2005 and CDM Regulations 2015, relate to activities undertaken by people. A lift installer could be prosecuted for a failure to meet the requirements of the Lifts Regulations, whilst a client who uses the lift has no duty in this respect (not being a manufacturer or installer under the Regulations).

However, a client has duties under the HSWA (Health and Safety at Work etc. Act) 1974 and specifically under the Management of Health and Safety at Work Regulations 1999, PUWER (Provision and Use of Work Equipment Regulations) 1998, CDM 2015 and WaH Regulations. These differences provide an enforcement authority with powers to deal with all parties who may be involved in, or affected by, a potentially dangerous situation and/or, as the case may be, works undertaken on a non-compliant lift.

I recall an expert witness appointment relating to a fatal accident in which the HSE adopted such an approach, serving Notices upon employers involved in relation to breaches of the WaH Regulations due to a deficient car top balustrade, and a further Notice on the original manufacturer of the lift (who wasn’t in any way involved in the accident), who had designed and installed the deficient lift under EN 81-1, and was therefore in breach of the Lifts Regulations 1997.

The key point to take from this is that all work at height must be risk assessed to ensure that the protective measures are suitable for the work to be performed.

The dimensional oddities and variations which have evolved in the development of U.K. domestic safety regulation originate in the traditionally narrow regulatory focus placed upon the location and/or context of the works to be regulated, whereas modern regulation may be considered purposive in terms of preventing some undesirable outcome and to be wide-reaching in its application.

The origins of the requirements may be traced back as far as the Building Regulations 1926, which required (subject to certain circumstances) handrails and toe-boards, but which were silent on the height of these. The Building (Safety, Health and Welfare) Regulations 1948 introduced a 3 ft (915 mm) height, an 8 in. (203-mm) high toe-board and a provision for no vertical gap in excess of 27 in. (685 mm). The Construction (Working Places) Regulations 1966 prescribed a height of between 3 ft (915 mm) and 3 ft 9 in. (1143 mm) with a minimum 6 in. (152 mm) toe-board height, and that any vertical gap should not exceed 30 in. (762 mm). Thereafter, a move to the SI System came about together with a rounding of the earlier Imperial measures to Metric dimensioning and subsequently the current dimensional requirements.

Building Regulations Approved Document K requires minimum 1100 mm high balustrades for protection at roof edges, balconies and edges of floors, which, in effect, are reflective of the fall risks from a lift car top, albeit that the 700 mm high balustrade provision under EN 81-20 would be unacceptable under Approved Document K.

BS 7255: 1989 recognised the hazard of falls from the car top and, whilst advocating the application of vertical screens, horizontal extensions to the car top and/or other suitable means, it fell short of a recommendation for car top balustrades on the basis that these could introduce particular hazards. I recall this train of thought to have been common back then, albeit that in the light of 25 years subsequent experience of EN 81-1, the resistance now appears bizarre or to have been misplaced (and possibly reflective of manufacturers seeking to minimise lift shaft headroom?).

Whilst my own preference would be for a standardised balustrade height of 1100 mm, I welcome the EN 81-20 prescription of a force/deflection measure in relation to the integrity of the design together with the reduction of the EN 81-1 850 mm horizontal measure to 500 mm. Whilst the minimum forces and deflections applicable under EN 81-20 differ from those in Approved Document K, the indication is of at least an equivalent level of safety, with the particular EN 81-20 provisions adopted to reflect the particular lift-related application. In my view, the EN 81-1 700 mm high balustrade was insufficient in terms of mitigating the risk arising due to a fall hazard horizontal distance of 850 mm, and I find the current application to a 500 mm horizontal distance questionable. EN 81-21 provides additional provisions applicable to extendable balustrades, one of which is that these should be easily and safely deployed and easily extendable which, in my experience, is not always the case.

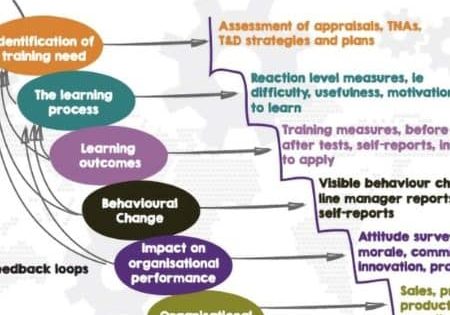

In summation, the U.K., with its extended history of workplace safety regulation, took a somewhat convoluted route to the current position as a result of which we have; under EN 81-20, 700 mm and 1100 mm high lift car top balustrades, 1100 mm high balustrades under the Building Regulations, and a 950 mm minimum height balustrade for construction works. However, these must be considered as the minimum requirements in each case, and in all cases, work at height is subject to risk assessment under the Management of Health and Safety at Work Regulations 1999 and, if it is unavoidable, to the provisions of the hierarchy of controls under the WaH Regulations (Image 1).

Get more of Elevator World. Sign up for our free e-newsletter.