Otis team shows off Tianjin CTF Finance Centre, a solid high-rise in the northern area.

The northern Chinese city of Tianjin, with nearly 14 million inhabitants, is fast emerging as a key municipality. The Tianjin CTF Finance Centre, a 97-story, 1,739 ft (530 m), super-tall skyscraper, rises above the new commercial district of Binhai and features high-end offices, serviced apartments, a five-star hotel and a shopping mall. Otis Elevator is proud of its role in making this dramatic and sleek structure possible.

Nestled against the Bohai Gulf portion of the Yellow Sea, Tianjin is the largest coastal city in Northern China and is a major seaport and gateway to Beijing. With the Tianjin CTF Finance Centre, the city now is home to the world’s seventh tallest building, the tallest building in the north region of China and the third-tallest building in Asia.

Otis provided 80 elevators, including 53 SkyRise® and 27 new Gen2® Comfort elevators for the project, as well as 22 Otis Link™ escalators and one car lift for transporting vehicles in four, below-ground floors. The elevator ecosystem features the Otis CompassPlus™ smart destination management system.

The Centre’s design is a dramatic addition to the city skyline. Its softly curving glass exterior integrates eight sloping, mega-columns that connect the centers and corners as the building rises. The columns enhance the structure’s response to seismic events and effectively increase the stiffness of the perimeter frame. The tower tapers dramatically to minimize surface area exposure to wind, sun and moisture. The building’s aerodynamic shape greatly reduces vortex shedding by “confusing the wind” and disrupting the opportunity for any resonating wind forces and loads on the structure. Square with rounded corners, the floor plate geometry enables unique interior fit-outs and customization options for occupants.

Not surprisingly, Tianjin CTF Finance Centre has won a number of industry awards, including the Royal Institution of Chartered Surveyors’ China Award 2020; the China BIM Certification Alliance’s Platinum Award; the Steel Structure Gold Award at the China Construction Metal Structure Association’s Annual Outstanding Engineering Awards; and Council on Tall Buildings and Urban Habitat 2021 Award for Excellence for Best Tall Building 400 m and above, Best Tall Building Asia, and Structural Engineering.

Ronald Lu & Partners used building information modeling (BIM), an intelligent, three-dimensional, model-based process, to design and execute the complex and distinct structure. BIM significantly reduced tower construction time and cost and played a critical role in optimizing the building’s striking, crystal-clear winding glass curtain wall, reducing the number of glass panels needed by more than 60% and contributing to the tower’s construction being completed four months ahead of schedule.

The tower also was designed to LEED® Gold standards by implementing strategies including a high-performance envelope, optimized daylighting and green landscaping. Otis contributed to the goal with its energy-saving products, including ReGen™ drives on SkyMotion® machines, Gen2 elevators and escalators in the building, and manufacturing in a way that’s kinder to the environment.

In 2007, Otis opened the world’s first green elevator manufacturing facility. Located in the nearby Tianjin Economic-Technological Development Area (TEDA), the Otis TEDA Elevator Center incorporates the most advanced energy-saving technologies to reduce site energy use by at least 25%. The facility produces environmentally friendly elevator systems, including Gen2 elevators. All 27 Gen2 elevators and 33 SkyRise elevators within the Tianjin CTF Finance Centre were manufactured at the Otis TEDA Elevator Center.

In addition to providing its elevators and escalators, Otis employed several innovative methods to streamline the installation process and beat the construction schedule. These included BIM in the transportation system design, an elevator “false car” work platform in the hoistway to speed installation, and innovative hoisting methods for lifting and locating multi-ton elevator motors and other equipment. The company’s 165-plus years of innovation in product design, customer service and construction made it an ideal partner for the Tianjin CTF Finance Centre, ultimately helping to ensure its position on an illustrious list of iconic buildings on the world stage.

Transportation System Details

In announcing Otis’ participation in the Tianjin CTF Finance Centre project, Otis China President Perry Zheng said:

“As China’s cities continue to elevate, Otis is reaffirming its leadership in high-rise elevator systems. We are pleased to bring our advanced technology and international experience to this prestigious new Tianjin landmark. Leadership, sustainable technologies, strong teamwork and responsiveness were crucial to winning this contract and are also the keys to our continuing success serving customers in China.”

Today, the dramatic structure stands as a testament to Otis’ long-standing ability to provide innovative and technologically advanced products and meet challenging construction requirements and schedules, ultimately delivering outstanding service to the customer.

Otis invented the gearless traction elevator in 1903, making high-rise buildings practical and ushering in the era of the modern skyscraper. Iconic tall buildings that elevate the world’s skyline, including the current record holder, the 829-meter Burj Khalifa in Dubai, together with tall buildings in China, such as the 492-meter Shanghai World Financial Center and the world-famous Shanghai Oriental Pearl Tower, demonstrate Otis’ expertise and breakthrough innovation.

“Meticulous planning, proven high-rise construction and installation experience and well-managed total solutions were the keys to our success on this project,” said Kam Man Wong (Ken Wong), MPM Field Management Director, Major Project Management Department, Otis Elevator (China) Co. Ltd., and the company’s project manager for the Tianjin CTF Finance Centre, continuing:

“An aggressive installation schedule, poor weather, particularly in winter when temperatures at the top of the tower dropped at night to minus-30 Fahrenheit, and challenging customer requirements tested us throughout the build. However, in part through the use of innovative design planning and installation techniques, we completed the work several months ahead of schedule.”

BIM

Otis used building information modeling (BIM) to design the transportation systems for the Tianjin project and integrate it into the overall construction model to ensure successful coordination with the building’s other systems. The use of BIM has grown steadily across many industries, and Otis has utilized it on building projects around the world for several years. Its BIMCreate design tool enables architects and designers to create customizable, configured 3D Revit® files for integration into overall building plans, rather than selecting from pre-existing files. BIM allows better structural decisions involving hoistway walls, elevator pit depths, overhead requirements, building interface attachments and other elevator equipment specifications. Building systems and subsystems are thereby finalized before ground is broken for construction, ensuring seamless integration. Wong explained:

“In the past, our installation processes and how they related to those of other contractors were reviewed and coordinated in traditional layout drawings to resolve any conflicts between the various systems and the building structure, and it was a time-consuming process. Using BIM to resolve integration conflicts is almost instantaneous and allows teams to propose alternative solutions to uncoordinated designs in real time. It also reduces the number of questions coming from the field during installation. We’ve been able to identify and solve problems and issues significantly in advance of physical installation, ultimately saving time and installation and material waste expense.”

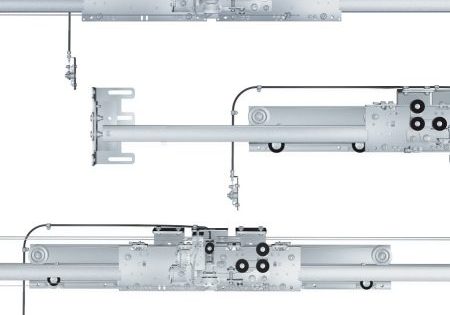

To ensure tight installation deadlines were achieved, Otis used several innovative techniques to speed material movement while not conflicting with work being done by the building contractor or other trades, including the installation of a “False Car” and improved “Hoisting Cage” methods.

False Car

The False Car is a temporary moving work platform inside the elevator hoistway used during installation of hoistway equipment, including rails, entrances and brackets. When combined with a “staged” installation method, it allowed Otis and the general contractor to work in the hoistway concurrently, saving valuable installation time. The False Car was equipped with a hoist motor and a safety device that rides at the bottom and rolls along each rail, providing a comfortable and safe work environment. Utilizing this installation tool allowed elevator installation to be started without scaffolding or even an elevator machine room.

The Hoisting Cage

Typically, in super-high-rise projects, construction utilizes elevators with the elevator machine room located at the top of the building. “The earlier we can complete the elevator installation, the earlier we can provide vertical transportation to assist the general contractor and other trades to complete their work,” Wong said.

However, with multiple machine rooms on the Tianjin project and machine room installations going on at different levels, a “Hoisting Cage” method utilized the tower crane to easily lift the cage into place and allowed it to be attached to the edge of the building slab at the necessary level. Once there, material could be pulled out from the cage using the ropes attached to the equipment. Utilizing this method, elevator equipment was arranged and hoisted to different floors in significantly less time — and with less of an impact on the construction needs of others.

The Elevators and Escalators

The 53 traction SkyRise elevators in the building represent Otis’ most advanced high-rise elevator to date, combining cutting-edge science and precision engineering. Each SkyRise elevator installation integrates industry-leading technologies to ensure the safe, reliable operation of the entire system. SkyRise’s features include a noise-blocking Q-frame cab and aerodynamic shroud, designed using computational fluid dynamics and wind-tunnel testing, to ensure a smooth, quiet ride, and safety brakes made from the same heat-resistant materials used for jet-engine nozzles.

To ensure peak performance of the Centre’s SkyRise system, Otis conducted advanced simulation and analysis to understand site-specific variables, including building sway and stack effect.

The SkyRise elevators serving the office floors feature Otis CompassPlus elevator destination dispatch management, which gets passengers to their destination as much as 50% faster than conventional systems. It all adds up to less waiting time, less crowding and fewer stops along the way. The elevators at Tianjin CTF Finance Centre also include a facial recognition system, a first for Otis in China, that’s integrated with the Otis CompassPlus fixture and allows passengers to request their destination without swiping a card or even touching the fixture.

The complementary, sleekly designed 22 Otis Link escalators serving the Tianjin CTF Finance Centre’s shopping mall are highly reliable and engineered to be quiet and smooth. All escalator components are designed and tested to ensure dependable performance over extended periods of time.

Otis engineers will continue to remotely monitor elevator and escalator equipment with the aim of identifying and preventing service issues before they arise, and the company’s eService portal gives customers instant access to real-time performance, maintenance and other critical equipment information.

Sustainability

To support the customer’s environmental goals, Otis provided some of its most energy-efficient products. The SkyRise elevators feature permanent-magnet SkyMotion machines that are among the most energy-efficient on the planet.

The Gen2 elevator coupled with a ReGen drive can reduce energy consumption up to 75% compared to conventional elevators without regenerative drives. The ReGen drive feeds energy usually lost during braking back into the building’s internal electrical grid, where it can be used for other building systems. The Gen2 elevator also doesn’t require any additional lubrication, eliminating the need for storage, cleanup and disposal of hazardous waste.

Otis escalators on site use ReGen drives to capture energy when descending, returning it to the power grid. Otis escalators with ReGen drives consume 60% less power than escalators without them. Otis escalators include smart lubrication systems that use up to 98% less oil than manual lubrication systems. Sleep mode operation and LED lighting further reduce energy consumption.

Additionally, the company’s CompassPlus destination management system maximizes carrying capability and minimizes passenger travel time, thereby saving significant building power usage.

The technologically advanced and aesthetically designed elevators and escalators Otis provided for the project are a fitting complement to the sleek and dynamic tower. The Tianjin CTF Finance Centre is just another example of how Otis meets the installation and construction requirements of its customers while providing technologically advanced, proven and innovative products.

Get more of Elevator World. Sign up for our free e-newsletter.