Climate Friendly to Climate Neutral

Apr 1, 2022

In this Industry Dialogue, your author discusses the big commitment of the Big 4.

In February, the NewClimate Institute, Berlin, Germany, in collaboration with Carbon Market Watch, published its annual Corporate Climate Responsibility Monitor. A summary reads: “Major companies largely fail the net zero climate pledge test. … Twenty-five of the world’s largest companies, in reality, only commit to reduce their emissions by 40% on average, not 100% as suggested by their ‘net zero’ and ‘carbon neutral’ claims, according to a new analysis.”

As no elevator manufacturer is included, your author (USB) took a closer look and asked the Big 4 — listed in alphabetical order below: KONE, Otis, Schindler and TK Elevator (TKE) — directly about their attitudes and concrete contributions toward climate neutrality.

USB: Which new technical features do your products include to become more sustainable?

KONE: Such energy-efficient and innovative solutions as, for example:

- Regenerative drives

- UltraRope® and energy efficient motors

- LED lighting with dimming

- Advanced stand-by solutions

- API solutions

Efficient use of durable and sustainable materials:

- Reliable, long-lasting equipment and, in the end when modernized, 90% of the metals used can be recycled

- Sustainable materials, e.g., green building-compliant materials, non-toxic durable materials, micro-scratch resistant materials.

Carbon neutral maintenance KONE Care DX:

- Smart and predictive maintenance

- Optimized and green fleet operations

- Innovative digital services

- Smart spare part changes.

The remaining carbon emissions will be compensated.

New trend: wooden construction. Our solutions are suitable for wood shafts.

Health and well-being solutions

Otis: Gen2® technology includes the following features:

- The ReGen™ drive captures and utilizes energy normally wasted as heat, reducing the need for cooling in the machine and, thus, energy consumption by up to 75% compared to a conventional drive.

- Flat polyurethane-coated steel belts (PU belts) are lighter and last up to three times longer than conventional steel ropes, reducing the use of resources. PU belts never require lubrication and thus reduce the use of fossil-based lubrications and waste.

- LED technology reduces energy consumption and lasts up to 10 times longer than conventional fixtures. It provides up to 80% energy savings for cabin lighting in interaction with standby operation compared to conventional lights.

- Standby Mode leads to up to 50% energy savings. Lights and fans shut down when there’s no demand.

More new sustainable products:

- Prefabricated modular elevator-hoistway combination

- Gen2 Switch

- CompassPlus™ Dispatching System

- SkyMotion™ 400 machine

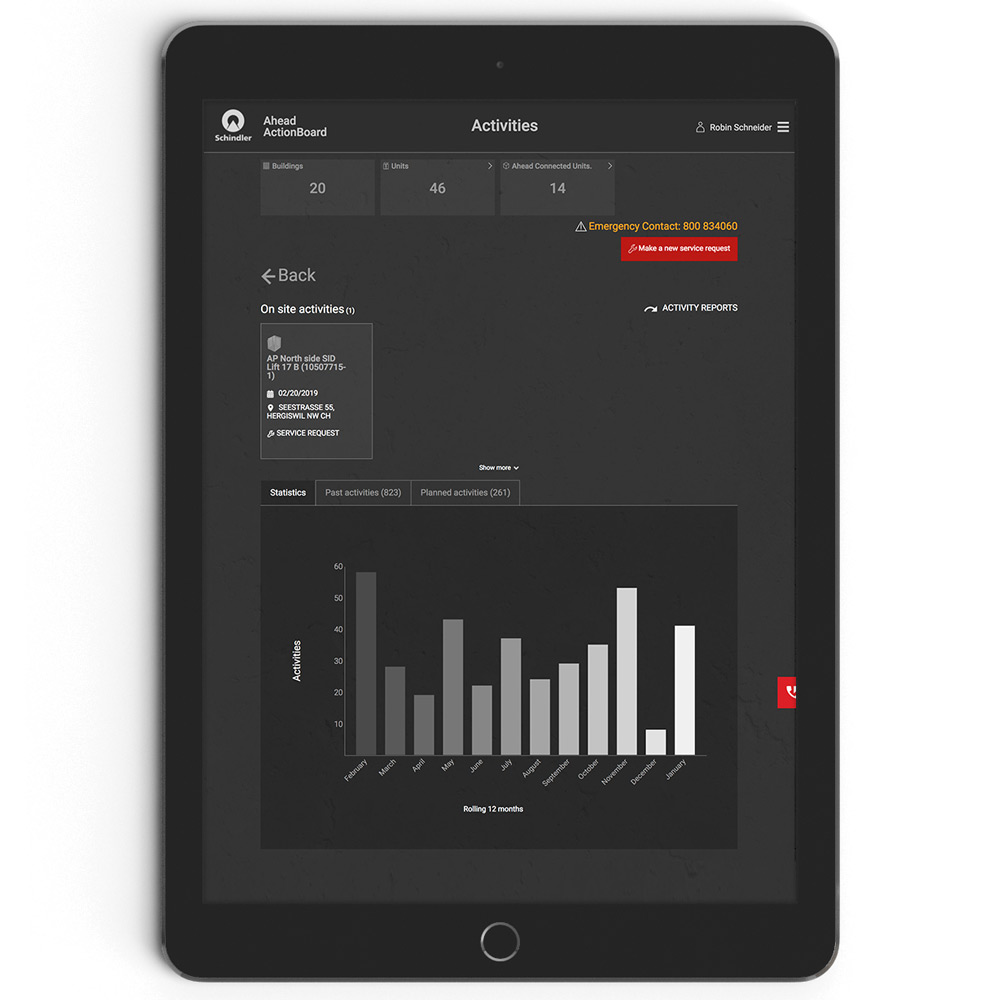

Schindler: Our digital innovations go from the product development phase (Digital Twin) to installation (Schindler R.I.S.E) to operations and maintenance (Schindler PORT and Schindler Ahead). Our Building Information Modeling (BIM) provides traceability and insights throughout the entire project lifecycle.

Our latest product generation improved energy efficiency by up to 30% compared to the previous generation.

Ahead offers predictive maintenance and electronic monitoring. The most important data are available in real time, and problems can be detected ahead of time. The service technician sent to the site already knows the problem before getting there. In addition, substituting physical checks and interventions with remote inspections and maintenance allows us to further limit our carbon footprint.

PORT technology uses advanced algorithms to coordinate all elevators and organize passengers’ routes efficiently. This reduces energy use by up to 40%.

TKE: Our innovative solutions, such as TWIN and MULTI, require less space and consume less energy, thereby reducing CO2 emissions significantly and making buildings smarter, more efficient and sustainable.

MAX is a cloud-based solution for customers. It analyzes real-time data from connected elevators and escalators, thereby enabling smart maintenance and optimal customer service: It minimizes downtime and the need for technicians to visit customers and branches, resulting in a significant reduction of CO2 emissions. MAX also helps to extend the service life of our elevators by approximately 30%.

With TWIN and MULTI, we reduce the space required for elevators in a building and contribute to reducing the embodied carbon of the building. TWIN elevator systems have two cabins operating independently in a single shaft. They need less energy, can move up to 40% more passengers than conventional elevators and occupy up to 50% less space. MULTI allows several cabins to travel simultaneously and autonomously in one shaft. The available shaft space can thereby be used more efficiently, reducing building space required for elevators by up to 50%.

USB: With which standardizations do your products comply?

KONE:

- ISO 25745: We received 23 best A-class ratings for elevators. Eight KONE escalator and moving walk models have received the best A+++ classification in the escalator and moving walk category.

- VDI 4707

Otis: The energy efficiency of our products is confirmed by our Environmental Product Declarations (EPD) in accordance with ISO 14025, which awarded both the Gen2 and the Gen360™ platform an energy efficiency class A:

- Gen2 Life

- Gen2 Stream High Rise

- Gen2 Stream

- Gen360 (launched in 2021)

The EPD meets the requirements of ISO 14025 and within this, the following ISO norms and others:

- ISO 14040 (2006)

- ISO 14044 (2006)

- ISO 25745-1 (2012)

- ISO 25745-2 (2014)

- EN 15804+A1 (2012 + 2013)

- ISO 14025 (2006)

Schindler: We provide EPDs in line with ISO 25745 for all our main product lines. Our latest product generation comes with the option of the highest level of energy efficiency (energy classification A).

We comply with the VDI 4707-1 standard.

Our products 5500, 7000, 9300 and 9500 are newly Green Mark product certified — the Singaporean green building certification.

TKE: Our elevators have received the highest energy-efficiency rating (Class A under ISO 25745-2). We also received our first certificate for the highest energy-efficiency rating (Class A+++ according to ISO 25745-3) in 2019 for the velino escalator.

Our R&D teams are guided by Life Cycle Assessment (LCA) studies based on ISO 14044. Some of our products, such as iwalk, are also certified to ISO 14006.

We publish EPDs, the first one for the Endura elevator line in the U.S. in 2017. Today, we have EPDs registered for a wide range of our elevators in the U.S., Latin America, Europe, China and Australia.

USB: Which processes did you establish in your company to contribute to climate friendliness?

KONE: We have set the targets for significantly reducing greenhouse gas emissions from our products, and to have carbon neutral operations by 2030. These targets have been approved by the Science Based Targets initiative. Baseline for targets: 2018.

We established an internal Climate and Environmental Excellence Program many years ago. As we pledged to become climate neutral by 2030, this means cutting emissions in our operations in half, and cutting emissions related to products and value chain by 40%, in accordance with the Science Based Targets initiative.

Our climate pledge is in line with limiting global warming to 1.5°C, which is currently the most ambitious criterium for setting science-based targets. Our commitment to sustainable practices is reflected in our strategy and values.

For example, we are shifting toward a low-emission vehicle fleet and renewable energy/electricity for all offices.

Resource efficiency and circular economy: 90% of the metals used in our solutions can be recycled, packaging materials can be recycled, durable solutions with long lifetime greater than 25 years. We aim to further increase the amount of recycled content in our solutions.

We publish EPDs in order to illustrate the environmental impact during the entire lifetime of solutions (third party certified). We also publish Health Product declarations to communicate about the material content and associated health effects of our products.

Otis: Based on our vision, one of our four key areas deals with Environment & Impact: We are constantly working to reduce the environmental footprint of our products, services and operations. At the same time, our goal is to improve efficiency and performance.

We pursue, overall, 13 Environmental, Social & Governance (ESG) long-term targets in four categories. They are in line with nine of the UN Sustainable Development Goals (SDG). We are a member of the UN Global Compact initiative since March 2021.

We meet the standards of the Global Reporting Initiative (GRI) and the Sustainability Accountability Standards Board (SASB). We will issue our first ESG report in spring 2022.

Our long-term targets:

- Achieve a 50% reduction of emissions by 2030

- Reach carbon neutrality for factory electricity by 2030

- Achieve 100% factory eligibility for zero-waste-to-landfill certification by 2025

- Complete ISO 14001 certification for all factories by 2025

Examples of sustainability-oriented initiatives:

- Several Otis offices and manufacturing facilities use energy from solar panels. Reduction of CO2 emissions by more than 30% from 2015-2020 globally.

- More efficient use of water by capturing and better using rainwater through efforts such as recycling, e.g., in Brazil. Reduction of water usage by more than 40% from 2015-2020 globally.

- Waste prevention pilot at the Florence, South Carolina, U.S. facility.

- Since the beginning of 2022, we are purchasing green electricity for the company’s headquarters in Germany, as well as a large number of Otis’ branches in Germany.

- In Germany, we have begun introducing electric cars for our field technicians and aim to expand this to additional employees in our own vehicle fleet.

Schindler: We support the goals of the Paris Agreement and are members of the UN Global Compact. We are constantly improving manufacturing processes. We are engaging with logistics partners to optimize shipping of our components.

Responding to climate change and the risks and opportunities associated with it are of utmost importance to the Board of Directors. Climate-related risks across the value chain, including management responses, are part of our Group Risk Radar.

We launched a climate scenario analysis in 2021. In line with the TCFD recommendations, physical and transition risks are being identified and their impact on the company’s business and strategy assessed using different scenarios. Results will inform our net-zero transition plan.

In 2021, we committed to set science-based targets (SBT) across our entire value chain.

We are a member of the RE100 global initiative to support the transition to 100% renewable energy in our Group. We are part of the sustainability-minded “We Mean Business Coalition.” We aim to procure 100% electricity from renewable sources by 2025.

Since 2017, we have been reducing the carbon footprint of our global vehicle fleet for installation and servicing. We aim to reduce the CO2 intensity of the fleet by 25% compared to 2017. Annual progress and further information can be found in the Corporate Responsibility Report and Annual Report.

With our major suppliers of production materials, we aim to perform independent sustainability assessments for 75% of our manufacturing purchases using a third-party tool EcoVadis.

TKE: We commit to reducing direct emissions (Scope 1) and emissions from energy purchases (Scope 2). In June 2020, we defined our first climate targets aiming at a reduction of our Scope 1 and Scope 2 emissions by 25% by 2030, and 50% by 2040, from a baseline in 2019. We joined the Business Ambition for 1.5°C initiative and committed to achieving net zero emissions by 2050 at the latest. Currently, we are reviewing our Scope 1 and 2 emissions reduction targets and working on the definition of our Scope 3 targets. All of these will be verified by the Science-Based Targets initiative to make sure they meet the criteria of the 1.5°C scenario.

Regarding other sustainability-relevant factors, such as our vehicle fleet, which is responsible for a large proportion of the company’s own emissions, a significant reduction will be realized through the conversion to electric and hybrid vehicles, as well as through digitally controlled route optimizations.

There will be a significant reduction in emissions generated in our facilities based on maximum energy efficiency and an increased use of renewable energies. For example, in the fiscal year 2020/21, we increased the share of renewable electricity across our global operations from 1% to 45%, and are aiming to achieve 100% renewable electricity by 2030.

Other emissions in our value chain are highly influenced by product materials and operational energy consumption. Energy efficiency, use of materials and circular economy principles will be the focus of our emissions reduction efforts.

USB: Which certifications did your company obtain in this field?

KONE: ISO 14001

We have received Singapore Green Building Product (SGBP) certifications for several solutions, and we have all certifications with the highest possible “Leader” ratings. The SGBP-certified solutions are recommended for Green Mark-certified buildings in the Asia-Pacific region.

We have also received an “Accepted” rating in the Byggvarubedömningen (BVB) assessment system for several solutions in Sweden. BVB is a Swedish nonprofit organization that evaluates solutions for buildings and drives the use of sustainable building materials.

We can also contribute to Green Building certifications, such as DGNB, LEED, BREEAM, Minergie-ECO and ÖGNI.

Otis: ISO Certification: All of our factories are certified to the environmental management standard ISO 14001. In Europe, five of our factories are certified to the energy management standard ISO 50001.

LEED Certification: We build sustainability-oriented factories according to LEED specifications. We built the first LEED-certified elevator factory in China (Chongqing). A factory in India (Bangalore) was awarded LEED Gold certification.

EcoVadis Certification: We were rated among the top 10% of all suppliers worldwide.

Schindler: More than 80% of our production sites are ISO 14001 certified, including our major production sites.

More than 95% of our production sites attained ISO 9001 certification for robust quality management systems, with the aim of reaching 100% by 2023 for our offices worldwide.

Several of our buildings around the world have been awarded green building certifications, e.g., LEED, BREEAM, Indian Green Building Council (IGBC).

Our latest product supports meeting green energy buildings standards. We support our customers in meeting green building standards such as LEED, BREEAM, DGNB, IGBC and Singapore Green Building Council (SGBC).

TKE: Close to 90% of our manufacturing sites are certified to the ISO 14001 Environmental Management System (EMS) standard. Fifty percent of our manufacturing sites are certified to ISO 50001 energy management standard.

We are investing in customer solutions that support green building certifications like LEED and BREEAM. Our passenger transportation systems are currently installed in 1,000 LEED-certified buildings.

In 2015, our facility in Middleton, Tennessee, U.S., received LEED Gold certification. In 2017, our new elevator factory in Zhongshan, China, achieved the LEED Gold certification for the office building and LEED Silver for the plant.

USB: Which awards/rankings/scores were awarded to your products and/or company concerning sustainability?

KONE: We have been recognized as a climate leader by CDP for nine consecutive years, receiving EcoVadis platinum and FTSE4Good and A class in MSCI.

Forbes ranks us among the best employers in the world (2017-2021).

For the past four months, our service technicians in Vienna, Austria, travel via e-bikes and e-rollers. The Verkehrsclub Österreich (VCÖ) has awarded us — together with the logistics consultant ECONSULT — with the VCÖ Mobility Award 2021.

In 2021, our LANE turnstile received two awards in the Red Dot Award Program; other Red Dot Design Awards were given for our Office Flow, Digital Experience Car and TravelMaster™ Premium Kit escalator design solution. In 2020, we won four Red Dot product design awards for our DX Class elevators. The company’s solutions were also awarded in 2016, 2015, 2014 and 2012.

Schindler: We engage with a broad range of rating agencies including:

- EcoVadis: Gold

- CDP: B

- Sustainalytics: ESG Industry Top Rated

- Financial Times: Ranked on top as diversity leaders in the engineering and manufacturing sector

- Forbes Magazine: Ranked as one of 300 most female-friendly companies worldwide (Rank 144)

TKE: The CDP organization awarded us an A rating for the second time in a row in 2021.

We top the machinery industry in the latest Sustainalytics’ global ESG rating, with more than 500 companies evaluated in this category. This ranking confirms the decision to make ESG a strategic priority, which is evident throughout the Group.

We support the 10 principles of the UN Global Compact and the “Business Ambition for 1.5°C” initiative, with a commitment to reduce the company’s emissions to net zero by 2050 at the latest.

Our first ropeless elevator system MULTI was recognized by The Alliance to Save Energy with its Innovative “Star of Energy Efficiency” Award in the Built Environment category.

USB: Which aspects did you intensify regarding the new German (green) government?

Schindler: The responses have been made on behalf of the Group as a whole, not our German entity in isolation.

TKE: As an international company headquartered in Germany, we are committed to reducing the environmental footprint of our products, processes, and operations to the greatest possible extent, regardless of the respective political leadership.

Company Leaders Speak

Janine Korytowsky, Quality & Environment Specialist, KONE

“We offer sustainable solutions and services throughout the building lifecycle, from early building design through choice of materials and development of solutions with high energy efficiency, carbon-optimized maintenance and long lifetime, until modernization and reusage and recycling of materials.”

Udo Hoffmann, Market Group Leader, Otis Central Europe, Otis

“Our approach to sustainability is holistic, covering the entire lifecycle from sourcing recycled and recyclable materials to equipping our factories with solar panels up to innovations such as the Otis ReGen drive that can feed energy back into a building’s grid. Now more than ever, it’s our responsibility to serve the generations that came before us, to sponsor the generations that come after us, and to deliver for the generations that are here today.”

Jörg Naescher, Head, Global Sustainability, Schindler

“We use a formalized sustainability materiality assessment to approach ESG. In 2021, we analyzed how Schindler products and services affect the lives of people around the globe. We identified the social and environmental issues that affect Schindler and how we do business. The results are used to guide our future commitments, targets and activities. But, sustainability goes beyond climate. Therefore, for instance, in 2021, we endorsed the UN Women’s Empowerment Principles and committed to uphold the Standards of Conduct for Global LGBTI (lesbian, gay, bi, trans and intersex people) Equality.”

Dr. Paula Casares, Head of ESG, TKE

“We do not judge the sustainability topic as a purely regulatory can-do, should-do or must-do requirement. For us, it is clear added value. As with all other key performance indicators at TKE, we track our own ESG-related targets continuously and report them on a regular basis. For us, it is not just about setting a target for the next 10 years and then moving on. We need to regularly review and update these targets, as change happens fast. You need to keep your targets well-defined, visible, and relevant.”

Also read: Market Updates: Germany and Austria

Get more of Elevator World. Sign up for our free e-newsletter.