Collins House

Mar 1, 2021

Otis works within space and time constraints to deliver advanced elevators to new landmark tower.

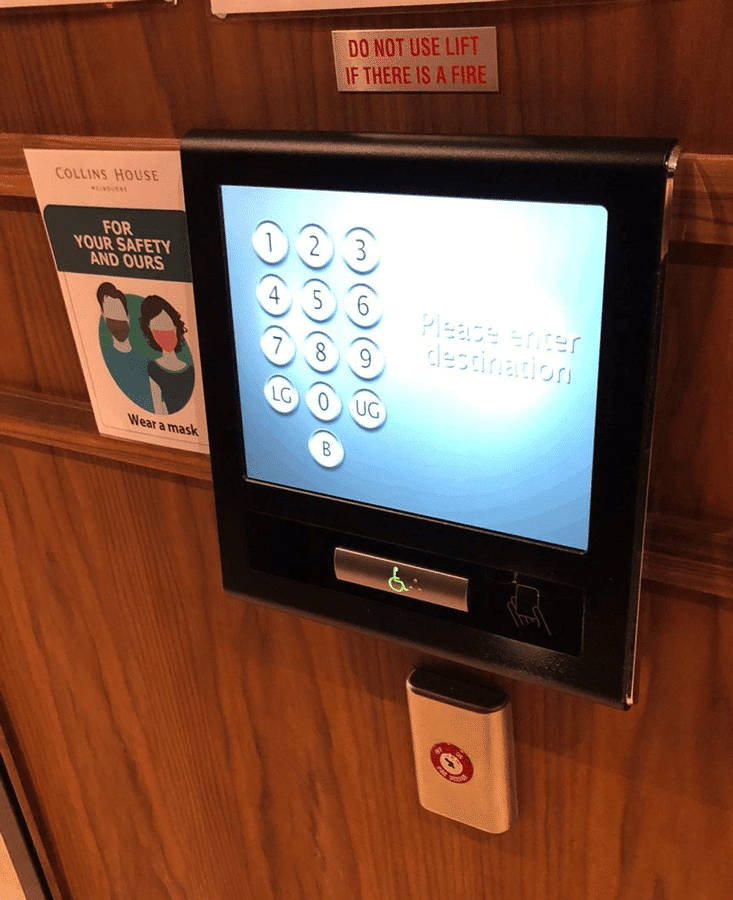

For more than 150 years, owners and managers of some of the world’s most iconic and unique buildings have called on Otis to deliver the solutions and service their buildings need. From the Empire State Building to the Eiffel Tower, Otis moves passengers throughout some of the world’s most famous landmarks. So, it should come as no surprise that the company was selected to provide its elevator products for the 61-story Collins House residential tower in Melbourne, Australia. Otis contributed two SkyRise® elevators and one Gen2® Premier elevator to the project, as well as the company’s CompassPlus® destination management system, products worthy of a landmark skyscraper noted for its unique design. Otis also successfully met unique installation challenges, not the least of which was delivering equipment to the site across a busy tram route that travels down Collins Street.

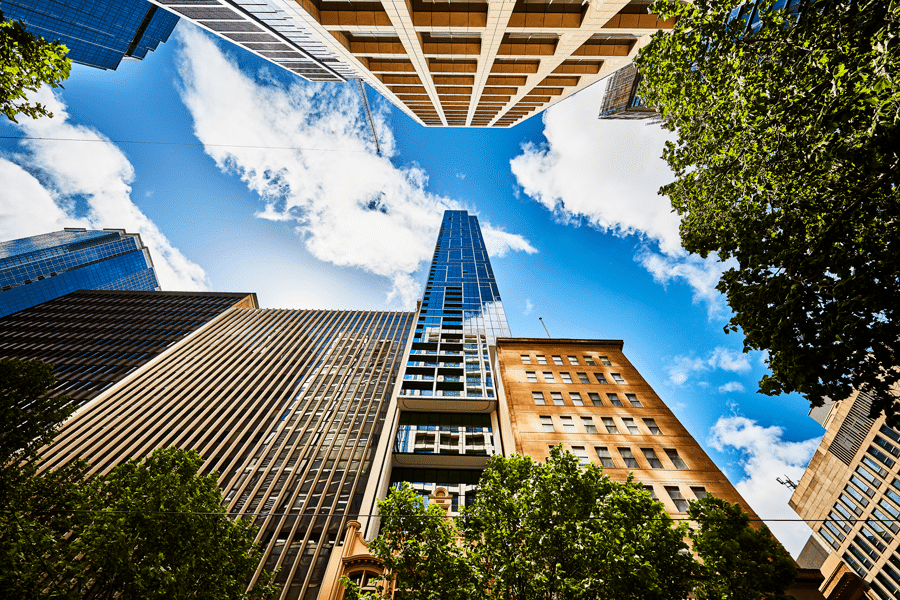

Collins House’s exterior dimensions measure 11.5 m (37.7 ft) wide at its base, making it Australia’s slimmest tower and the fourth-slimmest skyscraper in the world. Architecture firm Bates Smart designed this “skinnyscraper” to match the Collins House footprint, which isn’t much bigger than Melbourne’s typical house and land block. The building features a slenderness ratio of 16.25:1, coming in significantly less than the ratio of approximately 24:1 for New York’s Steinway Tower, the world’s slenderest skyscraper.

The sleek, contemporary tower incorporates the grand heritage façade of Melbourne’s historic Makers Mark building on downtown Melbourne’s Collins Street. NYC has its Wall Street, Paris is known for the Champs-Elysees, and Singapore boasts Orchard Road; in the same way, Melbourne has Collins Street, one of the most prestigious streets in Australia. With nearly 260 luxurious residences — a mix of multistory lofts, expansive single-level apartments and an exclusive penthouse collection — Collins House is a draw for its design, as well as its high-end amenities. The residences were designed with views in mind but are notable, as well, for their oak floorboards, marble splashbacks, glass cabinetry and brass fixtures.

Credits

Owner: Golden Age Group and joint-venture partner Deague Group

Developer: Golden Age Developments

Main building construction contractor: Hickory

Architect: Bates Smart

Elevator services provider, equipment manufacturer and component supplier: Otis

Because of the building’s small footprint, Collins House extends up from behind the Makers Mark façade and then cantilevers 4.5 m out on one side over an existing 11-story office building next door. (Collins House’s developer purchased the air rights above the building to allow the development to proceed as designed.)

Construction contractor Hickory Group used its construction method, Hickory Building Systems (HBS), to develop prefabricated structural modules designed to improve quality and safety and streamline the overall construction process. Collins House is the tallest residential tower in Australia to utilize modular components, and the HBS prefabricated construction method resulted in minimum disruption to traffic and a substantial reduction in the duration of the construction timeline — from 40 to 30 months. The self-supporting structure utilizes conventional formwork up to Level 14, at which stage the prefabricated units were used for the remainder of the project. A cantilever floorplate at Level 15 enables floor space to increase by approximately 35% to the very top.

While the small footprint was a challenge for the builder and the Otis design team, a single point of access at the front of the Makers Mark façade created issues with the amount of room available to maneuver various pieces of construction equipment and building material required. The logistics of delivering, setting up and moving materials and equipment during construction on the site required clear communication and well-organized, just-in-time delivery.

A strong history of customer service and innovation, coupled with experience in meeting challenging building design and installation requirements, allowed Otis to provide an ideal elevator solution for this distinctive, prestigious project.

Transportation System Details

The particularly narrow Collins House site required a rethinking of the structure of tall buildings. It was only through an inventive structural system (combined with cutting-edge construction techniques and advanced systems that met the building requirements in the time required) that a reinvention of the tall skyscraper concept was achieved.

Otis supplied a Gen2 elevator for Collins House that travels from the basement level to Level 19 and SkyRise elevators that travel from the ground floor to the upper floors. The three elevators utilize the same triplex elevator shaft, with the two SkyRise units changing to a duplex shaft after Level 20. “In addition, once we completed the Gen2 installation, Hickory used it to fit out the lower part of the building, while we continued the installation of the two SkyRise units above,” said Jeremy Miles, Otis’ technical support team leader for new equipment & modernization.

“Otis was chosen to provide the elevators for Collins House based on their industry high-rise experience and value,” said Hickory Project Manager Peter Frank. SkyRise, Otis’ most advanced high-rise system, integrates technology with space-saving design that gives building designers flexibility in realizing their visions.

SkyRise was perfectly suited for the “skinny” design of the Collins House project. The sustainable design of SkyRise minimizes space requirements, and the elevator’s SkyMotion® machines are among the most energy-efficient available. Their lighter weight makes them easier to install, and their smaller footprint saves space. The elevator’s controller is built with fly-by-wire technology, similar to that used in aircraft, to provide reliability in a compact design. The controller helps reduce energy consumption, while a patented control algorithm ensures a smooth ride.

The Gen2 system is one of the company’s best-selling elevators, with more than 1 million sold since its launch in 2000 (ELEVATOR WORLD, December 2020). Gen2 features flat-belt technology that allows for a compact design, energy-efficient operation and a smooth, quiet ride. The compact system gives architects greater design flexibility and building owners more rentable space. The flat-belt technology, ReGen®

Get more of Elevator World. Sign up for our free e-newsletter.