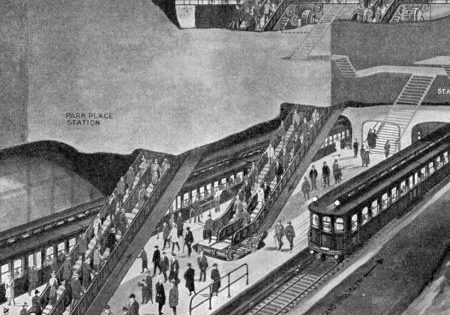

Common Escalator and Handrail Accidents and Their Causes

Sep 2, 2022

Escalators and moving walks are high-capacity machines which provide vertical transportation between floors in many different building types. Only one escalator transports 3600 people in 1 hour comfortably. These machines which we often seen in shopping malls and metros have a huge contribution on vertical transportation as they transport huge amount of people. On the other hand, they have more safety risks than the elevators.

In our country, escalators are placed on the market within the scope of the EU machinery safety directive and EN 115-1 is used as the harmonized standard. There are no big differences with this standard and its American version ASME 17.1. Therefore, escalators and moving walks are more universal and more alike than elevators. While the standards increase the level of safety over the years, accidents are not prevented completely.

Most frequent accidents are entrapment accidents. Entrapment may occur at different parts of the escalator. Frequently, feet of the passengers are entrapped between the steps and skirt. Especially children experience, such accidents when they are unattended.

To prevent such incident, the updated version of the code obliges, placing deflector on the skirt sheet.

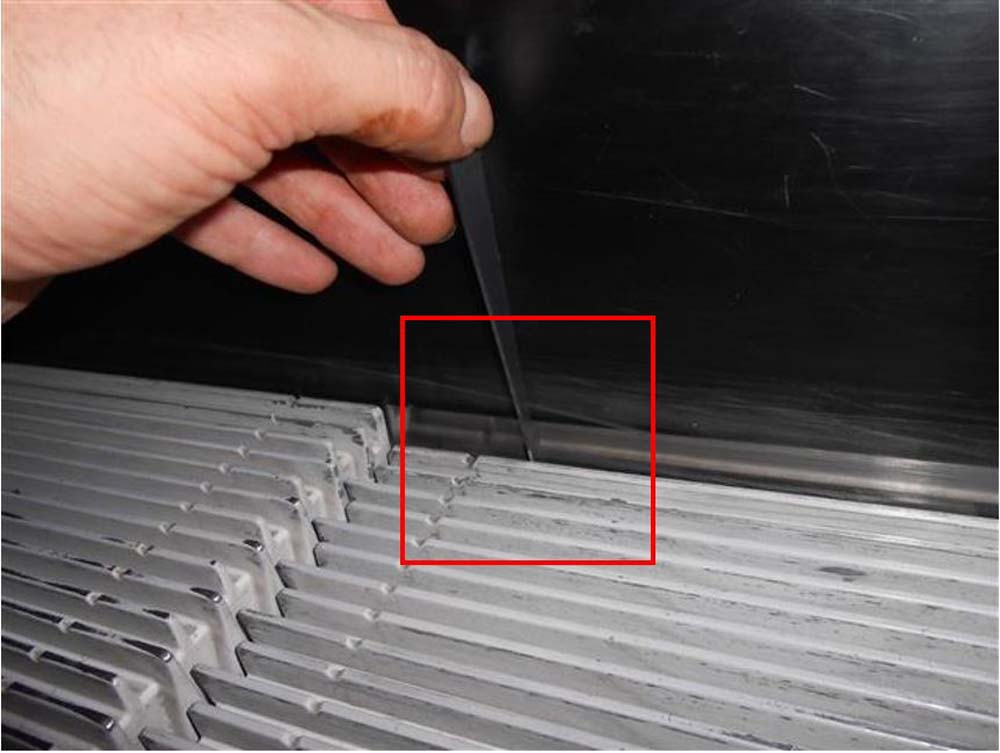

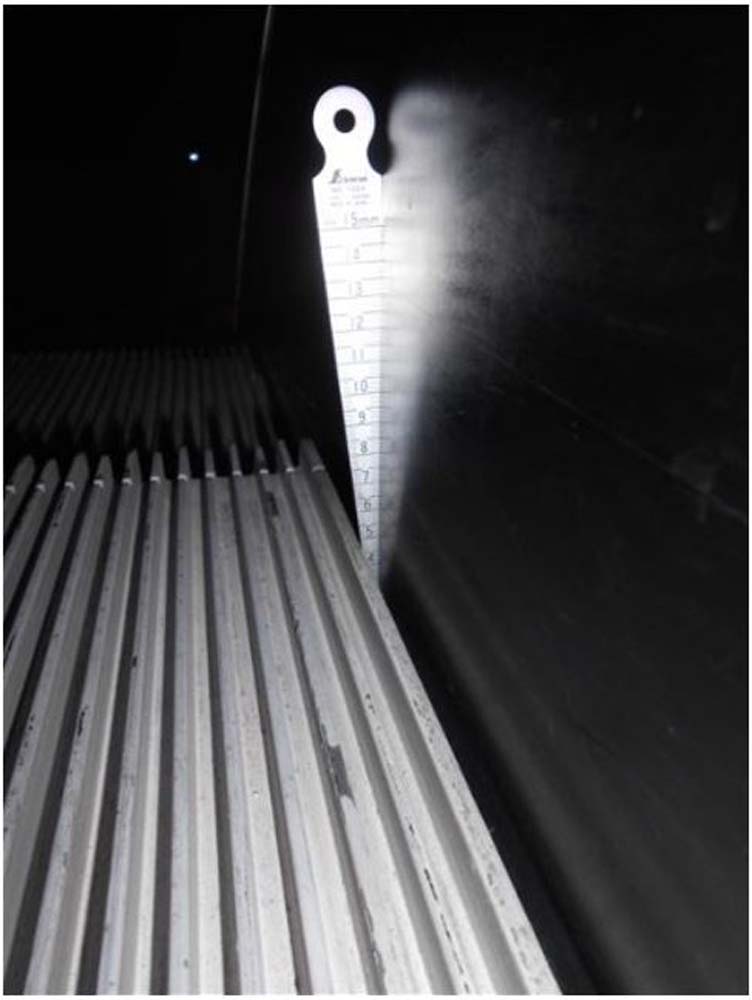

However, skirt deflectors may not be available at the escalators installed before 2010 while the brushes which are available are not the exact solution for entrapment. One of the reasons of entrapment is that the step-to-skirt clearances are not controlled. These clearances, which should not exceed 7mm with a maximum 4mm at each side, increase due to the elongation in the step chain or expansion of skirt plates because of the temperature differences.

Growing clearance increase entrapment risk. In order to reduce the risk, clearance should be measured during periodic maintenance and skirt sheet should be adjusted.

In some cases, bringing the shirk sheet near the steps do not solve the problem. While some steps move smoothly, some others rub against the skirt sheet. The reason is the asymmetrical elongation of the step chains which can be seen between the steps. Clearances appear to increase or decrease from right to left.

There is no safety device to rescue the feet entrapped between the steps and the skirt. Although there is a safety contact for the skirt, the moving step may entrap the foot and break the bones.

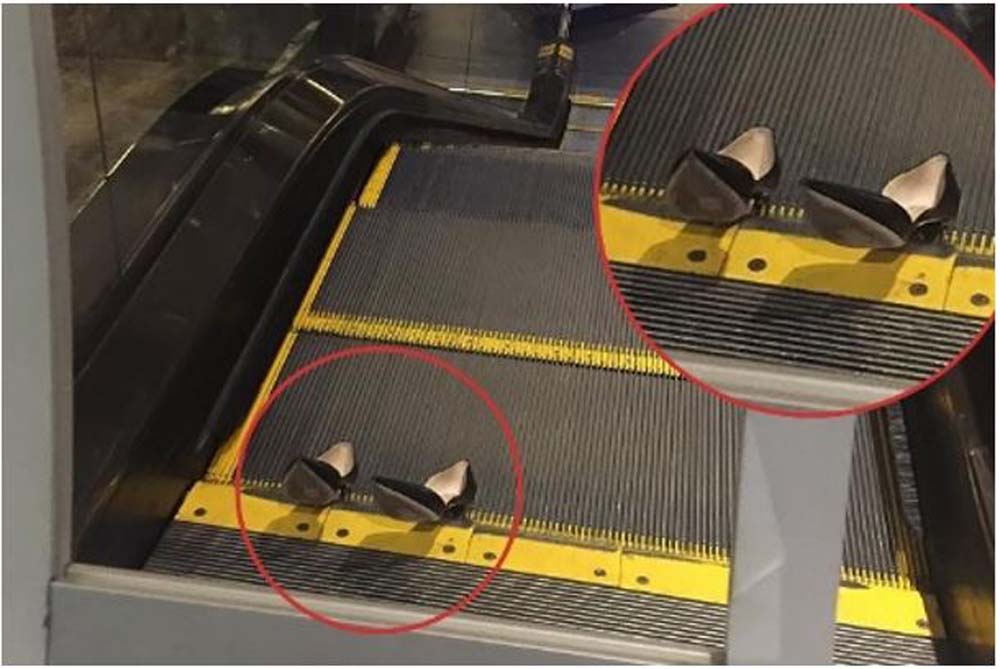

Another type of entrapment is being entrapped between the steps and the combs.

According to the standard, the distance between the comb teeth and the step grooves should not exceed 4 mm. However, maintenance personnel sometimes elevate the comb plates to prevent friction. It increases the risk of entrapment between the comb plate and the step.

The comb teeth must mesh with the grooves of the step or pallet surface at the minimum depth of 4 mm and the rest of comb teeth (h8), above the meshing must not be more than 4 mm from the step surface (h7). Adjusting these clearances decrease entrapment risk. Entrapment between comp plates stop the escalator. Plates trigger a safety contact. Plates are also made of soft material that can be broken when necessary, so that the entrapped elements are not damaged. The reasons of the changes in clearance may be dirty step rails or stretching of step chain. Such risks may be reduced by regular and correct maintenance.

A more dangerous cause of accident is broken steps.

If the steps are broken when there are passengers on them, they may cause big damages like breaking of the foot. When steps are broken, there is no safety device to stop the escalator until the comb plate contacts are activated. Therefore, the passengers are in danger starting with the moment of the accident until the escalator stops. Steps may get broken with different reasons. The most frequent reason is the asymmetrical step chains.

If the steps run with stretched step chains for a long time, then sudden jumps may occur when they are close to each other.

Additionally, dirty step rails make the step wheels stuck between the rails and dirt and get cracked and make the steps collapse.

In order to avoid breaking of the steps, maintenance should be carried out properly.

When step-to-step clearance increase, then smalls things like shoelaces and tassels get stuck. Step-to-step clearance distance should be maximum 6 mm. As bigger clearances bring high risk for entrapment, the escalator should not be in operation. Step-to-step clearances increase due to the elongation of the step chain.

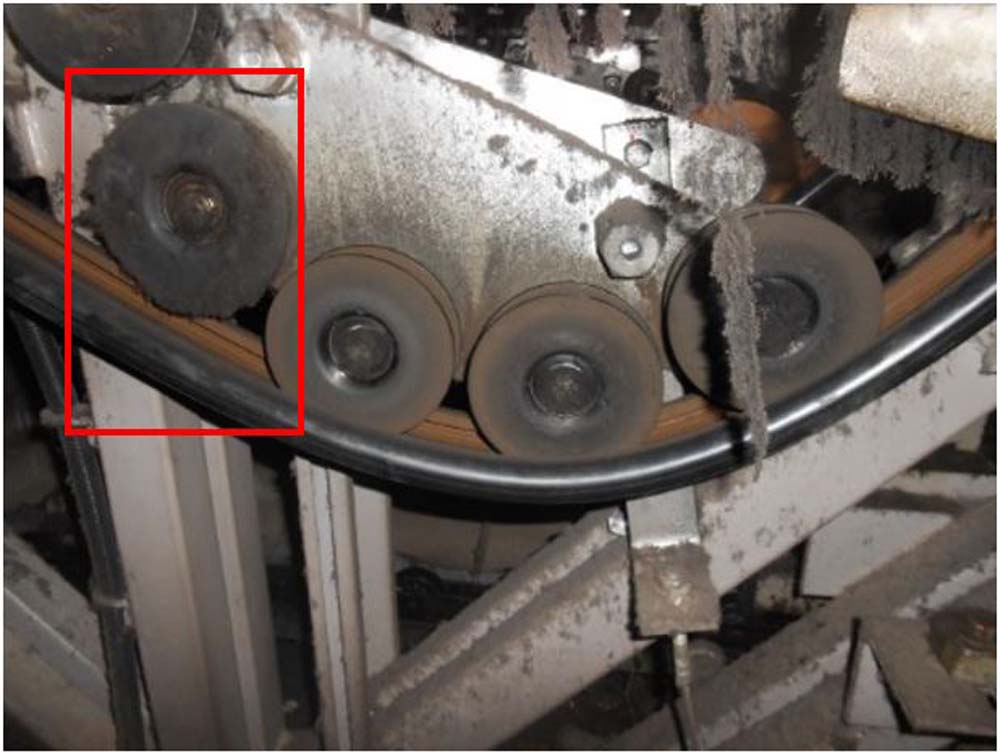

Another component that may cause low-risk accidents is the handrail. Handrails are designed at a width that users can hold them with their hands during travel. But there are also clearances between the handrails and the rails on which they run. If these clearances increase, the fingers of the passenger may be entrapped and get injured.

The biggest risk of the handrails may be their low speed. The speed of the handrail can have a tolerance of 0 up to 2% relative to the nominal speed of steps. That’s why your hands move forwards when you put your hands on the handrail of a moving escalator, but if the handrail is slower, then the passengers may lose their balance and fall. Handrail may be slow and thrust roller or handrail drum are often the cause of the handrails being slow or not moving. If the handrail thrust roller is worn out, the handrail is not pressed against the drum, so the handrail rotates slowly, as there is no sufficient friction.

If the handrail drum is worn, then it again revolves slowly as there is no sufficient friction. Water leaks between the handrail and drum of the escalators in metros frequently and it may also prevent the revolving of the handrail.

Walking or running on the escalator or moving walk also brings risk of fall. Therefore, the users should be warned with signage.

Additionally, escalators and moving walks that are not chosen correctly based on the intended use wear out quickly and bring accident risks. For example, as indoor type escalators used in public places are not manufactured with wear resistant material, they wear out more. Step chains stretch, step wheel cracks or handrail wears out more frequently. Such units are not sufficiently maintained as the global companies make monthly visits only. To provide security, design criteria suggested by EN 115-1 2017 should be used for escalators and moving walks for public use. This type of escalators, which are also called heavy-duty escalators, have more durable, larger and more protected parts.

The majority of the accidents that occur on escalators and moving walks that we use frequently in our daily lives are related to insufficient maintenance and wrong material selection. Accident risks will significantly decrease if the escalator and moving walk buyers and owners and the maintenance companies have sufficient knowledge about the parts which may cause accidents frequently.

Get more of Elevator World. Sign up for our free e-newsletter.