ECR Custom Elevator Interiors

Apr 1, 2021

The company’s vice president shares how his team approaches the engineering and design of interiors and ceilings.

ECR – Elevator Cab Renovations, which recently joined with MAD Elevator Inc. and the DMG Group of Cos. (ELEVATOR WORLD, August 2020), has been manufacturing custom elevator cab interiors for 33 years. Operating across North America, ECR is headquartered in Ottawa. Your author (LF) spoke to ECR Vice President of Product Development Jonathan Adair (JA) to gain insight into what the company has been doing so successfully for so long.

LF: What are some challenges your clients face?

JA: Some of the most common are how to select a new interior and obtain a timely quote, weight considerations, long-term durability, ease of installation, and retrofitting. There is a 15-25-year cycle for updating elevator interiors, so we want to make sure that our customers get to 25 years. Our overall goal is to use engineering and proactivity to solve common problems in the elevator industry. Making the right choice involves solving for a lot of variables, especially when you’re retrofitting an existing cab.

LF: How may the life of the elevator interior be extended once it has been installed?

JA: One solution our team has devised to ensure the panels in our cabs last as long as possible is reversible panels. Damaged and scratched panels or discontinued panel designs can limit the amount of use a customer may get from their interior. To combat this problem, we designed our A-Look and C-Look cabs to have reversible laminate panels, so if one gets scratched, the panel may simply be flipped to extend the life of the cab. Some of our clients will make a point of displaying a specific side for high-traffic days, then flipping to the other side so only one side is exposed on high-traffic days. Reversing a C-Look panel is very easy and can be done by building maintenance staff.

Another issue elevator interiors face is impacts on panels that can damage their edges. These chipped edges are caused by vulnerabilities in the joint between the side of the panel and front face. ECR engineers our panels with extrusions to protect the edges against impact and prevent or reduce chipping. In addition to elevating the look of a cab interior, the metal extrusions are very durable and protect the laminate, as they extend beyond the laminate itself and absorb impacts. This increases the life of the cab.

LF: Do you offer lightweight solutions?

JA: Since weight and capacity are such big considerations in the elevator world, ECR makes “Lightweight” and “Ultra Lightweight” cab interiors and ceilings to accommodate every situation. For example, if panels had never been accounted for in a cab’s weight capacity, and the owner wants to add them, an entire interior can be added to a cab within an additional 250 lb.

The option to work on the elevator floor independently of the cab interior is a benefit our customers value, as it is a lot easier.

LF: How have you addressed the challenge of installation time downtime?

JA: For us, it was important to tackle this question, as one of the key problems faced in our industry is the time it takes to install a cab interior. To challenge ourselves to reduce installation time, we engineered solutions to minimize required measurements down to three or fewer, and removing any requirements to use glue or trim metal. As all the systems are self-aligning, no further measurements or calculations are required. All this really speeds up installation, which helps to cut down on installation time. Likewise, elevator downtime is cut to only a few hours.

LF: Must the cab be dismantled if its floor needs to be repaired?

JA: Definitely not: we know it may become necessary to periodically update or repair the floor of a cab and that being able to perform that work easily and with minimal impact on the rest of the cab components is a much better solution. So, we designed our kickplates to be removable to allow for floor work with easy kickplate removal and reattachment after the work is done. Likewise, in the unlikely event of a kickplate being damaged, it can be easily removed and replaced without the removal of any other parts on the cab wall.

The option to work on the elevator floor independently of the cab interior is a benefit our customers value, as it is a lot easier. We’ve even allowed for the eventuality of a change in floor height when new material is used. In this case, a custom kickplate can be specified to accommodate the new floor.

LF: What do you recommend consumers do when planning and designing their cabs?

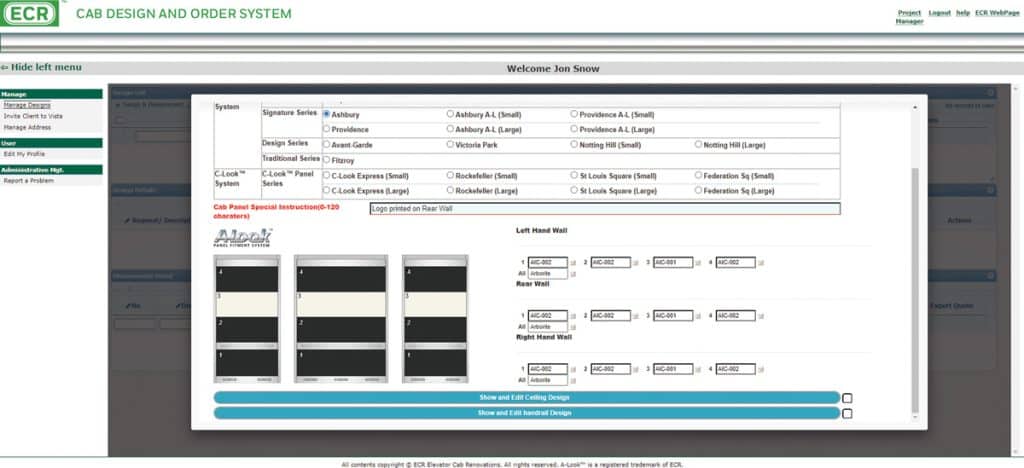

JA: We offer our online Cab Design Tool, which allows the customer to see all the choices available in a cab in every possible configuration. This allows them to plan for a few scenarios and communicate with their team members to come to a fast and accurate consensus. The use of this tool also streamlines communication between stakeholders to cut down on redundancy, time and errors. Finally, the ability to receive an immediate quote using the tool allows for accurate comparisons.

LF: Are your products a result of R&D?

JA: Yes, through our in-house lab at our Ottawa headquarters. Having our own R&D allows us to solve for everything from environmental effects on the panels (humidity, temperature changes etc.) to durability, including glass shatter tests and overall testing, to make sure we’re using the best materials to create the best outcome with scientifically proven machines and techniques. This goes beyond simply ensuring everything meets code; it is also ensuring the products will perform as designed in all environments to ensure long life and customer satisfaction.

Get more of Elevator World. Sign up for our free e-newsletter.