Learn about troubleshooting the elevator motor and variable-frequency drive (VFD) and safety procedures.

Certain aspects of elevator maintenance and repair are nonelectrical, such as lubricating and refurbishing hoistway guide rails or improving airflow around a hydraulic reservoir. But, most of this work, especially when the symptom is chronic controller shutdowns or error codes, involves the electrical system. When that is the focus, the basic idea is to locate and replace the defective component without resorting to a random approach, which will inevitably see replacing good components and be a costly waste of maintenance resources and cause of increased downtime.

This article discusses some electrical troubleshooting techniques applicable to electrical equipment in general and specifically relevant in elevator repair and debugging of new designs. To begin, don’t get in over your head. To perform elevator electrical repair, the worker should be an accomplished electrical technician with detailed knowledge of safety features built into the motion-controller operating system.

Learning Objectives

After reading this article, you should have learned about:

♦ Diagnosing causes of elevator motor problems

♦ The relation between the elevator motion controller and VFD

♦ Gathering information prior to elevator fault diagnosis

♦ Precautions for measuring 480-V systems

♦ Instrumentation used in elevator diagnostic procedures

Elevator fatalities are extremely rare, but, tragically, they do take place. As a precaution, a fundamental rule in elevator design and maintenance is that a door interlock mechanism must prevent the car from moving whenever the door is not closed and securely latched. Also, the interlock must prevent the door from opening when the car is moving. In an instance when a child was crushed in an elevator between the car floor and the top of the door opening, investigators determined that proper maintenance procedures had not been observed. In

re-terminating two wires that had been temporarily disconnected, they were inadvertently reversed, disabling the door interlock. Technicians must do whatever it takes to ensure that mistakes of this nature do not occur. Constant reference to schematic and pictorial diagrams is essential, along with written notes on any temporary alterations to control wiring. A digital camera is very helpful in this regard and to document completed work.

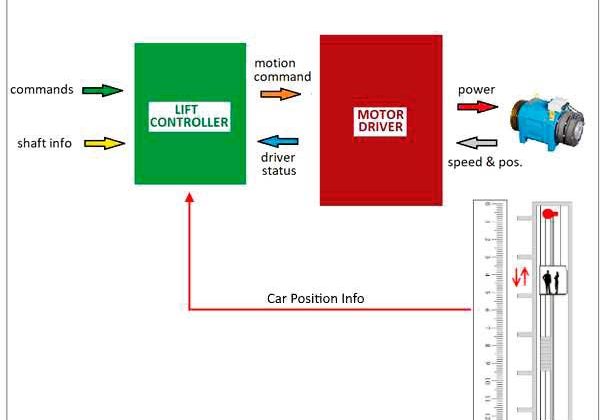

An elevator motion controller, like a PC in the home or office, is a digital processing device, and it is prone to freezing up or crashing, which means that the attached equipment stops working until the situation is resolved. The solution is often to reset or temporarily power down the system. This may restore normal operation, but, unfortunately, does not reveal the cause of the shutdown.

Most motion controllers have a small alphanumeric readout that will display an error code such as “E-12.” The user manual that accompanied the original elevator installation should contain a listing of error codes and how to clear the fault. If the manual is not available, an Internet search with make and model should provide error codes and other information. Another possibility is to call the manufacturer and speak to technical help. In this connection, it is helpful to install a telephone jack adjacent to the motion controller, along with a worktable so schematics can be referenced. (The motion controller is usually in the machine room, a concrete environment below grade where cell phone service is problematic.)

Error codes, however, are not infallible. It is like looking for a fault after an automobile crash has taken place. Sometimes, the information you need is lost in the event. If the fault recurs, you will need to institute the electrical troubleshooting procedures that follow. To succeed in restoring service, since downtime must be kept to a minimum yet safety and reliability must be ensured, an orderly work protocol is essential. To begin, the technicians should be in an information-gathering mode. This takes several forms — interviewing the operator and reviewing the history of the installation, assembling available documentation, and visually inspecting the site.

In an office building, hotel or manufacturing facility, there are usually one or more individuals familiar with day-to-day operation of the elevator or bank of elevators. These workers may perform routine tasks such as resetting the motion controller if it crashes, inspecting doors at each floor to see that they are firmly closed, checking branch circuit breakers, etc. In the event of a significant malfunction, an onsite electrician or outside elevator technician may be called in, and, at this point, a serious diagnostic procedure is in order.

A good way to start is to interview those familiar with the installation, particularly if they were the first to become aware of the malfunction and called maintenance resources or an outside elevator technician. These persons may not know an amp from a lampshade, but it is likely that one of them has a good sense of the installation’s history and may know the cause of the malfunction. Close attention should be focused on the event. Did it come on abruptly or gradually? Did it come about in the course of an electrical outage? Did users report any unusual sounds or a burning odor in or around the car or machine room? The answers to these questions may point to a quick resolution.

The next stage in the investigation, depending on the nature of the problem, is to visually inspect the car, taking a good, hard look at the door mechanism and user-accessible controls and indicators. Either immediately before or after that, visual inspections of the motion controller and motor are in order.

If the outage began recently, you can look for any sign of heat in the motor or in individual components in the motion controller. Beware, however, that even after the machinery has powered down, hazardous high voltages, even in excess of the system voltage, may be present. This is because a rectifier can increase the DC voltage to a higher level than the AC input and because large electrolytic capacitors are capable of storing significant amounts of electrical energy for a long period of time if there is no parallel resistance to bleed down this voltage.

Many elevator electrical problems occur in either of two areas: The motor and associated control devices and wiring, or the motion controller and associated control devices and wiring. Given information gained from the user interview, visual inspection and the nature of the malfunction, it may be obvious where to begin.

We’ll start with the motor. It may be completely unresponsive, or it may be overheating and cutting out, a chronic problem that afflicts aging motors, because, in time, the internal insulation becomes less efficient. This can be caused by (and, in turn, be a cause of ) heating, which is first noticed when the ambient temperature is high and/or the elevator is getting a lot of use in conjunction with heavy loading or if there are fluctuations in the electrical supply.

At one time, elevators were generally DC, because speed control was needed. Unlike a DC motor, the speed of an AC motor cannot efficiently be varied without causing overheating merely by reducing the voltage. All this changed in the 1960s with the introduction of the VFD, which permitted the speed of off-the- shelf AC induction motors to be varied by changing the duty cycle of a quasi-square wave power input at the motor terminals. One of the advantages in this arrangement is that induction motors are brushless, eliminating brush and commutator maintenance. VFDs are quite reliable, but when an elevator motor fails to perform as expected, this is one area to examine, as follows.

There are still many DC elevator motors in service, and they work well if you are willing to do brush-commutator maintenance. (A simple rectifier is used to derive DC from the AC power supply, and it is easy to check and repair, if needed.)

Regardless of the motor type, it won’t perform well if the AC supply is inadequate, so that is the place to start. There are many varieties of power-quality instrumentation available, and the user manual (which can be downloaded from the manufacturer’s website) explains how to take readings and interpret the results. This article, however, will assume you are using a handheld digital voltmeter with inputs insulated from ground.

Most VFDs that can power an elevator motor operate at three-phase 480 VAC with enough available fault current to cause multiple arc-blast fatalities, even if the victims do not contact live surfaces. The general philosophy in performing electrical work is that, where possible, the electrical supply is to be disconnected to power down the equipment under investigation. This is not possible when voltage and current readings are to be taken. Extra precautions are then required to avoid shock and arc-blast injuries.

In discussing voltage and current measurements, we’ll begin upstream. In determining the diagnostic procedure, technicians generally consider accessibility issues and endeavor to begin midway between the main disconnect and motor terminals to verify a large block of circuitry right away.

In taking high-level voltage readings, precautions are always required to avoid electrical shock hazards. High-voltage lineman’s gloves provide good protection, but even so equipped, you should not touch a live wire or terminal. Users periodically inflate high-voltage gloves with compressed air to detect any puncture or leak. When taking high-voltage measurements, work boots should be dry and have thick rubber soles free of cuts or excessive wear. The floor should be dry. Concrete should be considered a conductive material, so it is a good practice to throw down a thick, dry rubber mat. Only fully insulated electricians’ tools should be used.

To take 480-V readings, a multimeter with large, heavy probes and insulated inputs is necessary. The meter must be rated for the voltage and available fault current present at the main lugs. These ratings are invariably marked adjacent to the meter’s inputs.

Poor power quality as measured at the main disconnect or VFD input will result in erratic drive and motor operation or complete failure to start. Phase-to-phase and phase-to-ground readings should be within 1% of each another. These measurements should be taken both with the motor off and on, and fully loading (with the car moving).

Current measurements are best made using a properly rated electrician’s clamp-on ammeter. Clamp around each phase conductor in turn with the motor running and loaded. Current variations among phases may be expected to exceed voltage variations. 10% is acceptable.

Excessive voltage and current variations can be attributed to poor power quality from the utility, component failure within the VFD, cabling or termination defects, or faults within the motor. If all phases measure the same but drop when the motor is connected, there could be bearing or other mechanical trouble in the motor, or binding in the elevator mechanism.

The VFD schematic diagram shows that the first and final stages are mirror images of one another. In the rectifier stage, three-phase AC merges to become two-wire DC. In the inverter stage, the two-wire DC splits back into three-phase AC, now pulse-width modulated to control the induction-motor speed. In the rectifier stage, utility power, line 1, line 2 and line 3 are connected to the midpoints of three diode pairs, which rectify three-phase, 480-V (sometimes 600-V) utility power at the input, creating bipolar DC, which is filtered through an LC network to remove AC ripple. This pure DC is applied to the two-conductor DC bus, which conveys it to the final inverter stage.

The DC bus voltage is higher than the AC line voltage, even though there is no power transformer in the system. This is a consequence of the fact that a full-wave rectifier output voltage is based on peak-to-peak, not root-mean-square (RMS) voltage at the input. Along the DC bus in a 480-VAC system, it can be expected to measure 679 VDC, which is 1.414 times the AC value.

To function properly, a VFD requires a pure, stable voltage on the DC bus, free of significant ripple. To measure ripple, use the multimeter in VAC mode. Any ripple over 1% is problematic. It will disrupt the inverter stage and cause variations in motor speed and torque.

If there is excessive ripple, look to the filter network. Sometimes, the inductors open, which would cause no voltage to appear on the DC bus, or a few turns are shorted. But, more likely, one or both of the electrolytic capacitors has become faulty.

To check the capacitors, it is necessary to power down the unit. To do this, move the main disconnect to the off position. As most electronics technicians are aware, electrolytic capacitors operating at a high voltage retain a potentially lethal charge long after they are powered down. The shock hazard is severe in a 480-V system. In addition to the large capacitors in the rectifier section, there may be distributed capacitance throughout the system. Before proceeding, after the VFD has been powered down and the disconnect locked out, each of the capacitors and any other locations in the circuitry that could retain a charge must be discharged. The incorrect way to do this is to shunt out the terminals using a screwdriver or similar tool. The high current involved is likely to damage the capacitors by puncturing the thin dielectric layer. The correct procedure is to connect a low-ohm, high-wattage power resistor equipped with insulated alligator clips across the terminals. Use high-voltage gloves.

Any resistor/capacitor combination has a certain time constant, which is a function of the resistance and capacitance. During discharge as the voltage declines, the rate of change also declines, so that 0 V is approached but never fully attained. Therefore, it is necessary to take measurements at each capacitor and potential circuit node to ascertain when a safe level has been reached. Only then can the components be safely tested with an ohmmeter, and still, there is no need to touch a bare wire or terminal. Use only fully-insulated electricians’ tools.

To test a discharged capacitor, one of the two leads must be disconnected to take it out of the circuit, eliminating any parallel partial impedance that may give a false reading. First, visually check the capacitors. If there is any sign of swelling or distortion, leakage or burnt appearance, the capacitor is faulty and should be replaced. Check terminations for corrosion and loose joints. It’s a good practice to pull apart and reconnect all push-on connectors to polish the joints.

There are various types of capacitor, diode and semiconductor testers. Some laboratory-grade instruments test semiconductors by applying the correct DC biases and then injecting a test signal. The output is measured and evaluated. However, bad components can often be detected by simple multimeter tests.

To see how a good electrolytic capacitor reacts when ohmmeter-probed, connect the meter to a known good component. If it is currently in a discharged state, the resistance reading will rise or fall, depending upon which way the meter’s internal battery biases it, forward or reverse. The ohm values will change rapidly at first, then more slowly as the endpoint is approached. If the probes are reversed, the readings will progress in the opposite direction. Electricians call this characteristic electrolytic capacitor behavior “counting,” and it means the capacitor is functioning. (Non-electrolytic capacitors generally do not do this, because their capacitance is too low.) However, this is not a true dynamic test. At the full DC bus voltage, a capacitor that passes the ohmmeter test may actually be faulty. If inductors and capacitors test good, and the terminations are OK, but there is still ripple, you may have to replace components one at a time to find the culprit.

To check the diodes, again lifting one lead to take the components out of circuit, check with the multimeter in ohms mode. The device will conduct one way but not the other way. That is because the ohmmeter battery is forward or reverse biasing the diode. This also is not a true dynamic test, but it is likely to detect a bad diode, which is either shorted or open.

Measurements are done quite differently for the output side, using different instrumentation because the voltage level is comparatively low, and the frequency is far higher, especially when you consider the fast rise and fall times of the pulses as frequency components.

The final, inverter stage of a VFD has the following inputs: the two-wire bus voltage, 679 VDC for a 480 VAC system, and the low-voltage data stream that comes from the elevator’s motion controller. This consists of six inputs applied to the base terminals of the six insulated-gate bipolar transistors. These switching transistors modulate the high voltage from the DC bus and output a high-voltage, high-current, three-phase pulse suitable for powering the elevator motor. As seen in the VFD schematic, these semiconductors have internal diode layers, which can be checked with an ohmmeter. Also, voltage measurements can be taken at the six outputs to see if they are within 2% of each another.

When the motor is operating poorly or not at all, we will naturally want to look at the power applied to it. This may be measured at the VFD output terminals or at the motor input terminals. The voltages and waveforms may not be the same due to imperfections that may exist in the cabling or terminations.

For clarity, the VFD schematic does not show the PWM data conductors from the motion controller, nor does it show a ground conductor. Assuming the DC bus has been verified, next is to look at the power as conveyed to the motor. A conventional RMS multimeter in volt mode is not able to accurately read this signalized voltage, because it exhibits a pulse-width-modulated non-sinusoidal waveform. The reason for this inability is that such instrumentation typically has too much bandwidth. Consequently, it overresponds to irrelevant high-frequency components applied to the DC bus voltage in the VFD inverter section.

The Fluke 87V multimeter, which includes an internal selectable low-pass filter, is suitable for this kind of work. When the user activates this filter by pressing a yellow button on the front panel, the Fluke 87V will display accurate voltage, current and frequency readings in the VFD output to the motor.

In elevator applications, startup is critical. Most VFDs permit automatic startup to be enabled. The output can go to a designated frequency after a fault has been cleared or after the system has been manually reset following an emergency stop signal. Multiple auto-start modes are possible. Since passenger safety is always the prime consideration, this behavior must be designed with that in mind.

Learning-Reinforcement Questions

Use the below learning-reinforcement questions to study for the Continuing Education Assessment Exam available online at www.elevatorbooks.com or on p. 121 of this issue.

♦ How is AC ripple measured in a VFD DC bus?

♦ How are capacitors tested?

♦ How are capacitors discharged?

♦ Which instrumentation is required to measure a VFD output?

♦ What is the purpose of a VFD inverter section?

Get more of Elevator World. Sign up for our free e-newsletter.