Bringing instruction directly to the jobsite

“It is our philosophy at AEG that all elevator accidents should be avoidable.”

So states Mark Boelhouwer, president and CEO of American Elevator Group (AEG), a coming-together of well-established elevator service companies — 17 so far — focused on growth. “Some people will say that eventually there will be an accident and somebody is going to get hurt — it’s just a matter of time,” said Boelhouwer. “We here don’t believe that at all. It is our belief that accidents can be eliminated if service technicians are properly trained, follow procedure and are equipped with the appropriate gear. This is a fundamental operating philosophy of our group.”

With emphasis on safety in the elevator industry steadily escalating, currently in development is a next-generation approach to broadening it further: a fleet of self-contained mobile classrooms — called Mobile Elevator Safety Units — that deliver comprehensive safety instruction directly onto operating jobsites. Elevator service technicians are trained on-location in the principles of the SAFE 9 Program, also referred to by some as the Nine Safety Absolutes, which focuses on nine specific approaches to maximizing elevator safety and preventing injuries. Beyond simply the list of guidelines recommended by the National Elevator Industry, Inc. (NEII), or a static handbook or brochure on elevator safety, the practical hands-on training aspect of SAFE 9 (with SAFE an acronym for Safety Absolutes Field Evaluation), was developed for AEG by Lou DeLoreto, an elevator safety education veteran, currently the group’s senior vice president and lead instructor for the program. DeLoreto explains:

“Looking back over the history of the elevator industry since its beginnings over 100 years ago, I observed that serious injuries to workers have been attributable to the same types of causes, a pattern broadly breaking down into nine categories. Based on decades of experience practicing elevator safety, and more recently with my company, Elevate Safety Systems, I endeavored to focus on and emphasize these nine categories as a basis for helping to save lives. This led to the creation of this program, in conjunction with the Elevator Learning Center, that all of the companies in the AEG group could follow, including key rules and specific practices for each one of the nine ‘absolutes.’ The program involves implementation of each absolute in a live group educational setting, with training on equipment that mimics and simulates what the techs will actually be encountering in the field. This learning-by-doing approach gives them a much better chance to succeed, while their participation in one of these sessions results in three credits toward the CET certifications they require to further their careers.”

Delivery of in-person SAFE 9 instruction via use of the Mobile Elevator Safety Unit was conceived as an alternative training solution for elevator service companies, especially smaller ones with a limited amount of space and number of employees. Getting technicians to and from a training center involves significant travel time off the job, while conducting effective, field-simulated training in a cramped warehouse or office environment would be a major challenge — if even possible.

The Elevator Learning Center’s idea was to develop a highly flexible method of providing practical training while minimizing disruption to the companies’ productivity. The mobile session can be conducted indoors or out, on a loading dock, in a parking lot or spacious garage, or anywhere on a jobsite that space and weather will allow. Each session can accommodate from five to 20 technicians, which enables simultaneous training of multiple teams. A typical session lasts approximately 3½ hours, so participants can be on the job for the better part of a full day.

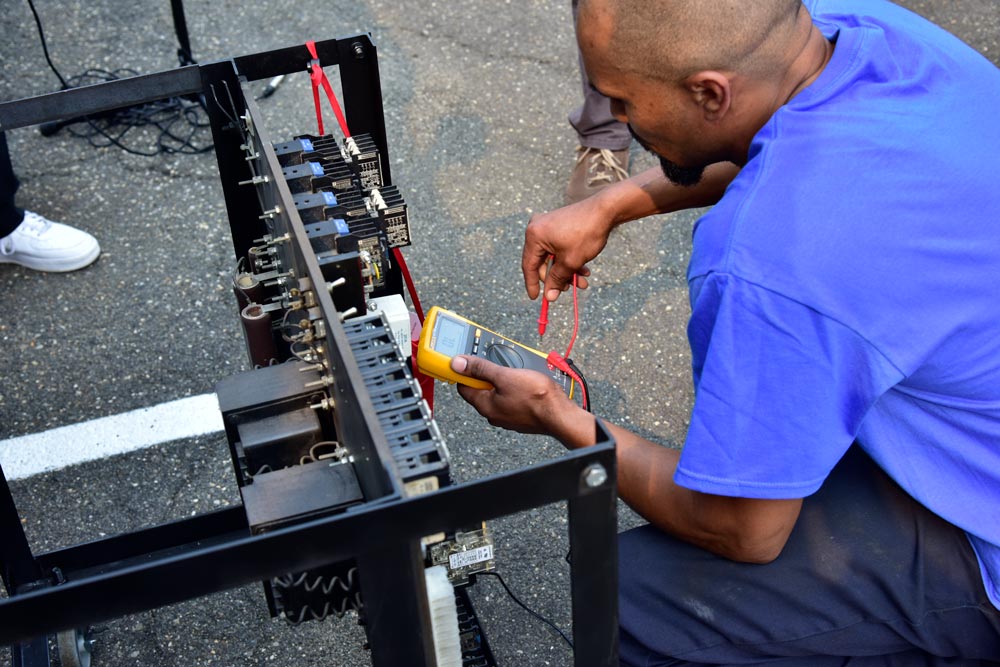

Each Mobile Elevator Safety Unit includes all the devices necessary to train the SAFE 9 program: Inline disconnect switches, top-of-car access using a car-top simulator, pit stop switches and access procedures that show technicians how to properly gain access into the pit, and electrical equipment simulators for teaching how to properly disconnect power to the various elevator devices. The vehicle also includes a roof-mounted I-beam that extends off the back for practical training in fall protection by having the technicians hang from the beam, strapped into their harnesses, as they actually might in the field.

Frank Campione, director of Field Safety and Training for D&D Elevator Maintenance, has experience in the field. He is currently an instructor aboard the Mobile Elevator Safety Unit, and emphasizes the magnitude of the safety mission:

“To me, safety is the most vital priority in the elevator industry. These mechanics work on very heavy and potentially dangerous equipment, including mechanical, hoisting and rigging, and electrical. To remain safe, they of course need to stay on their toes at all times but, most importantly, they must have meaningful knowledge and guidance with which to operate. The more safety training they receive, the safer they can be. It’s the repetition that keeps them safe, so every year we will be offering the latest in safety training rules.”

Carl Alongis, the Elevator Learning Center’s director of Education and Safety Training, and a certified OSHA instructor, points to an additional feature of the Mobile Elevator Safety Unit:

“While this program is beneficial to new people coming into the industry, it is equally so for experienced technicians and mechanics. While at a company’s location, we can conduct an onsite audit of their fall protection and other safety equipment, and if it’s worn, damaged, out-of-date or otherwise not up to required standards, we can take it out of service and give them all new equipment, right there, on-the-spot. On board, we also have pre-certified rigging equipment, so, if their current equipment is not up to spec, we can swap it out with new and have the old sent out for repair and recertified for future use. This way, at the end of the session, we can send the technicians back into the field with equipment we know will work safely.”

The mobile training concept was developed by the Elevator Learning Center, an outgrowth of D&D, both now part of AEG. Central to the process has been Robert Schaeffer, CEO of D&D and a vice president of AEG. Throughout his career, Schaeffer has been a strong advocate for and enabler of education in the elevator industry, with particular emphasis on safety. He entered the elevator field as a helper and mechanic at D&D, a company formed in 1981 by Ted Dettmering and Tom Davies. In 1984, Davies left the company, and Schaeffer became a shareholder and assumed various roles at the company, a period during which he says he “wore every hat to test my mettle in many different areas,” eventually becoming president and CEO of the company. In 1995, he joined with Nunzio Meccariello, by then also a shareholder, to buy out Dettmering, and, in 2004, Michael Bonardi, D&D’s current president, was brought in as a principal. In August 2020, Meccariello began the process of retiring, and the company sought to recapitalize to expand the Elevator Learning Center to a more national scope, leading to its current affiliation with AEG.

In the late 1990s, Schaeffer began assuming a major role in promoting elevator education and safety. Following a term as board chair of the National Association of Elevator Contractors (NAEC), he became education chair and oversaw the group’s development of the Certified Elevator Technician (CET) program. Recalls Schaeffer:

“At the time, I perceived a growing demand for better training and considered it vital to get out as much education as possible. This led to development of the CET program, which is continuously updated over a five-year period to include the latest concepts, technologies and code requirements. We formed a certification board of nine members to create an accredited scheme of certification up to ANSI and ISO guidelines and standards. Within the ANSI scheme, this board was charged as the certifying body to oversee all applications testing and ensure that all criteria were strictly met and filed. By 2010, this had become an official, certified program based on ANSI guidelines. We saw this as a major benefit for NAEC, its members and, particularly, smaller companies that didn’t have the resources to do their own training.”

Following New York State’s approval of the CET program for apprenticeship, in 2002 D&D launched its own internal apprenticeship training program, at the time the only standalone program of its kind. With the passage of time, Schaeffer took note of a growing labor shortage in construction trades, and in particular, regarding elevator mechanics. He observed that NYC’s Third Party Witness program was increasingly causing seasoned mechanics to shift their career focus from installation and repair to inspection, while many older mechanics were retiring altogether. Continues Schaeffer:

“By 2017, this labor shortage had become severe, and the market for mechanics was hurting. While we had this ongoing apprentice program, we weren’t able to keep enough people coming through to meet market demand. In an effort to fill out our team, we did an email outreach to around 17,000 elevator techs and found that no one was out of work. That’s when we realized that the only way for D&D to have a sufficient number of qualified technicians was to create them ourselves.”

Safety Absolutes Field Evaluation (SAFE) 9

- Car Top Access

- Pit Access

- Mechanical Stored Energy

- Fall Protection

- False Cars & Running Platforms

- Hoisting and Rigging

- Jumpers

- Electrical Safe Work Practices

- Lock Out/Tag Out

Thus was born the Elevator Learning Center, which opened on Oct 3, 2018, with the mission of training and hiring techs, at first just for D&D and its elevator platform (ELEVATOR WORLD, February 2019), but with plans to make the training available to other companies, in any location, via distance learning. Now, the Mobile Elevator Safety Units are being deployed as the next evolution of delivering safety training to the industry at large. The initial unit will serve the New York/New Jersey region, with plans for more to be rolled out for the Midwest and Southern regions, and ultimately the West Coast. Concludes Schaeffer:

“Today, taking it to the next level, the Elevator Learning Center is partnering with the AEG group of companies, which have mechanics and technicians requiring additional education for their licensing renewal, CET certification renewal and QEI (Qualified Elevator Inspector) renewal. The employee base of the AEG companies is now over 1,100 strong and growing, and we are in the process of in effect building a small college. Plus, the center is planning to offer its safety and education training to other companies outside the AEG platform in the near future. As per Mark Boelhouwer’s belief, bottom line it’s all about avoiding as many elevator accidents as humanly possibly via training and education.”

For more details and video of on-site SAFE 9 training, go to Mobile Elevator Safety Unit.

Also read: Elevator Industry Safety Net

Get more of Elevator World. Sign up for our free e-newsletter.