EN 81-20’s Impact on Elevator Door Detectors

Jun 1, 2015

In August 2014, two new standards covering elevator design (EN 81-20:2014) and installation requirements (EN 81-50:2014) were released in Europe. These replace EN 81-1:1998+A3:2009 and EN 81-2:1998+A3:2009, which were 15 years old and needed upgrading to comply with modern safety requirements. It is expected the new standards will also be adopted in China, South America and Australia.

EN 81-20 dictates the design requirements for passenger elevators, as well as passenger and goods elevators, regardless of the drive system used. EN 81-50 describes safety components, as well as research and calculation methods.

Many factors influenced the creation of these new standards, such as:

- Improvements in safety due to changes in proven technology and the need to reflect changes to the state of the art

- The incorporation of essential health and safety

- Requirements from modified European Union (EU) directives

- The elimination of reported errors

- The clarification of the text and incorporation of proposals resulting from interpretation requests

There are no longer separate standards for hydraulic lifts. Risk analysis and compliance with the essential requirements of the Lift Directive are key. Examples of new requirements are:

- Increased strength of doors, car and well

- Increased lighting in the elevator car

- The need to prevent people from leaving the car if it is stopped between floors

- Improved materials used in the car enclosure (such as flameproof materials and safety glass)

- Better classification of loading conditions and safety using loading vehicles (forklifts, etc.)

- Increased refuge space in the pit and headroom

- A pit control station and improved car-top control

- Improved pit access (ladders, control positions, etc.)

- Emergency lighting on the car roof

- An improved balustrade on the car roof

- A door-bypass control to prevent the deliberate bypassing of safety circuits (using shortcuts)

Both new and old standards will be valid during the current 36-month transitional phase, but beginning August 2017, EN 81-1 and EN 81-2 will no longer apply.

How does EN 81-20 affect elevator door detectors?

The specific part of the standard relating to elevator door detectors is covered in section 5.3.6.2.1.1 of EN 81-20, which discusses automatic power-operated doors as follows:

“The following applies:

- The kinetic energy of the landing and/or car door and the mechanical elements which are rigidly connected to it, calculated or measured at the average closing speed shall not exceed 10J.

“The average closing speed of a sliding door is calculated over its whole travel, less:

- 25 mm at each end of the travel in the case of centrally closing doors

- 50 mm at each end of the travel in the case of side-closing doors

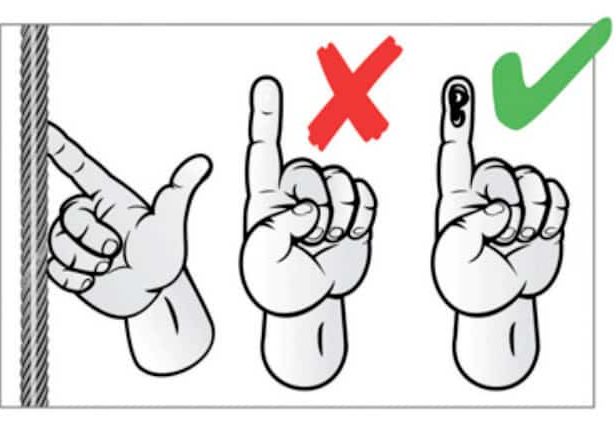

- b) A protective device shall automatically initiate reopening of the door(s) in the event of a person crossing the entrance during closing movement. The protective device may be rendered inoperative in the last 20 mm of door closing or gap.

- The protective device (e.g. light curtain) shall cover the opening over the distance between at least 25 and 1600 mm above the car door sill. The maximum detection height has been reduced from 1800 mm to 1600 mm.

- The protective device shall be capable of detecting obstacles [that are at least] 50 mm [in] diameter.”

Manufacturers of safety edges now have to guarantee that their products can detect objects with a diameter of at least 50 mm. This has a significant impact on the number of diodes used in traditional safety edges. Avire has developed unique test equipment that can automatically plot the protection coverage of a safety edge.

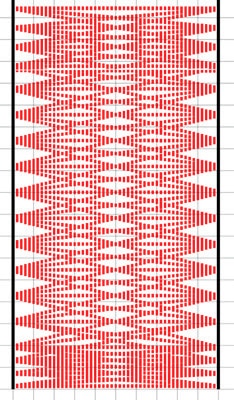

Figure 1 was plotted using a 50-mm-diameter object that was scanned vertically 18 times between two detectors mounted 1,000 mm apart. The continuous red vertical line indicates a trigger. Gaps in the vertical line indicate no trigger. As can be observed in Figure 1, the spacing of an 18-diode detector is not sufficient to ensure 100% detection coverage with a 50-mm-diameter object at the detector edge. The diagonal beams used within Avire detectors effectively fill in the pattern away from the edge.

It is easier to see the impact of the diagonals on detection capability by reducing the test object to something much smaller, e.g., 15 mm – Figure 2.

The standard way to resolve this issue with poor coverage at the surface of the detectors is to increase the diode count so that inter-diode spacing is less than 50 mm (Figure 3).

To counteract persistent obstructions when closing the door, the protective device may be deactivated after a predetermined time. This could be due to a physical obstruction or vandalism, such as chewing gum placed on the detectors.

In case of failure or deactivation of the protective device, the kinetic energy of the doors shall be limited to 4 J if the lift is kept in operation, and an acoustic signal shall operate at any time the door(s) is (are) closing.

This implies that when the safety edge detects a fault condition, this should be conveyed to the door controller to limit the closing force of the doors. The failure of the safety edge can be communicated in many different ways, from the most simple (where the door controller identifies a permanent trigger of the detector diagnostic output) to more sophisticated diagnostic protocols.

The implication, if the diagnostic output is a simple form of relay, is that it should be configured as “normally closed” to ensure the system fails safe if the detector, wiring or power supply is compromised. Alternative solutions include protocols such as CANopen and customer-specific protocols based on the RS485 physical layer. It is also important to note that during the fault condition, an alarm (acoustic signal) should also sound when the doors are closing to warn pedestrians.

Conclusion

The new requirements of EN 81-20:2014 are not mandatory until August 2017, so there is no need to panic. It is expected that most elevator manufacturers needing to supply new fully compliant EN 81-20 lifts will probably switch completely to new products around the middle of 2016. Some may do this sooner, but it is not essential. However, it is important to start discussions with a supplier of light curtains that has a good understanding of the new European regulations and can offer solutions to meet your system’s needs.

Get more of Elevator World. Sign up for our free e-newsletter.