Hoist Rope Longevity

Feb 1, 2021

In this Readers’ Platform, your author says proper installation and maintenance ensure long life and safety.

by Fartash Razmjoo

Many in the industry may have noticed that an excessive number of elevators have had their ropes replaced or scheduled for replacement much sooner than in the past. Hoist rope problems have become some of the most significant maintenance concerns for both elevator contractors and building owners. Rope replacement is expensive, increases the cost of maintenance and interrupts the normal operation of the building for days and even weeks.

Elevator manufacturers claim that the quality of the ropes is not as good as it used to be. On the other hand, hoist rope manufacturers claim that not only has the quality not decreased, it is better because of modern manufacturing technologies and tighter jurisdictions and standards. Rope manufacturers believe that the new elevator designs, with their smaller machines, rope sizes and more aggressive sheave designs, put more tension on the hoist ropes, and this eventually reduces the ropes’ lifespan.

I think both claims are correct to a certain extent, but, apart from the quality of the ropes or the fact that newer designs may put more tension on them, installation techniques and proper maintenance play a crucial role for keeping the ropes in good condition and extending their lifespan.

Over the years, I have talked with many technicians and mechanics in the industry, and I can say that when it comes to installation and maintenance of ropes, there is a lot of room for improvement in the training of elevator personnel. In this article, I discuss some important areas that should be considered during installation and maintenance of hoist ropes to prolong their lifespan.

Storage and Handling

- Ropes should be stored in a clean and dry area and protected against corrosion, dirt, rain and direct sunlight.

- Extra caution should be taken during transportation and handling to avoid physical damage to or twisting of the ropes.

- The floor should be cleaned before laying out ropes on the ground.

Installation

Rope installation methods may vary from manufacturer to manufacturer, but all installation techniques — no matter how demanding they are — should be followed and implemented correctly. Proper training plays an important role here. Failure to follow the manufacturer procedures can damage the components and reduce rope life. Regardless of the installation techniques used, certain procedures must be followed to ensure ropes and sheaves are in good condition.

Rope and Sheave Relation

- In any rope replacement, the new ropes should be the same type and size as the original ropes.

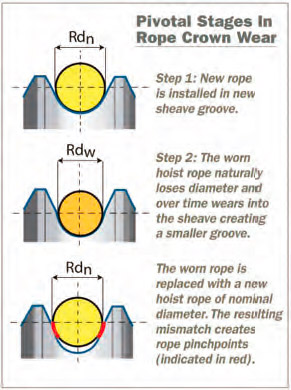

- Hoist ropes and sheaves are in contact with each other more than any other components in the elevator system and, thus, have a great effect on each other. Over time, friction between rope and sheave gradually reduces the ropes’ diameter. This reduction allows the worn hoist ropes to sit more deeply into the sheave grooves and creates a new groove within the original groove (Figure 1). When this happens, a replacement rope in the worn sheave groove creates pinch points that reduce the lifespan of the new rope. Because of this, many manufacturers and experts recommend that the ropes and sheaves be replaced at the same time.

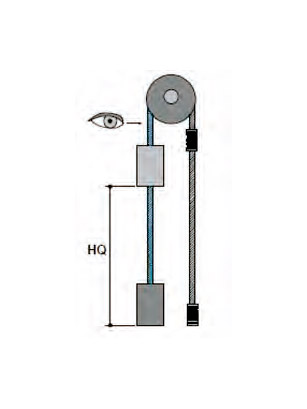

- Misalignment will damage the ropes and sheaves. According to Brugg Lifting, a fleet angle as small as 4° can reduce rope life by 33%. Extra caution should be taken to minimize the fleet angle (Figure 2). This can be accomplished by making sure that the drive and counterweight sheaves are aligned; making sure that, in 1:1 roping, the center rope on the drive sheave is aligned with the center of the car and counterweight; and by making sure that, in 2:1 roping, the drive and deflector sheaves are aligned with the pulley (sheave) of the car and counterweight.

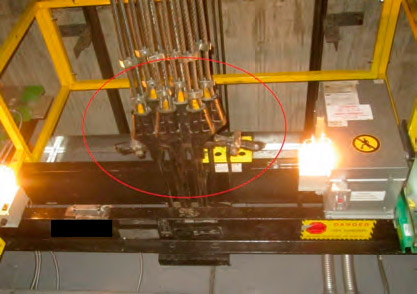

- Reviewing the ropes to ensure none sits lower in the sheave groove. If one does, it could indicate either improper rope tensioning or damage to a sheave groove (Figure 3).

- All sheave grooves should be inspected for excessive wear or damage. Sometimes, soft sheave material will allow the ropes to imprint the sheave groove. Figures 4 and 5 show examples of excessive damage to sheave grooves. All these damages should be found and prevented well before such a condition exists. This will happen if proper maintenance is in place.

Twisting and Untwisting Ropes

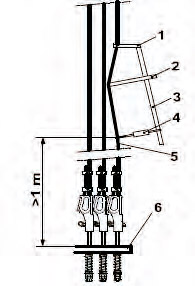

Rotation and twisting have significant effects on rope life. Rotation, especially in high rises and using steel-core ropes, can cause the outer strands to untwist, placing the majority of the load on the rope cores, which deteriorates the rope over time. Anti-rotation devices and torsion locks should be installed properly to avoid this condition on ropes. (Figures 6 and 7).

- Twisting can put extra pressure on the ropes, causing excessive friction between strands. It is important to make sure the ropes are not twisted during installation (in either direction). This is more challenging in situations like machine-room-less devices or double wrapped ropes with complicated configurations. Failure to avoid twisting of the ropes during installation will reduce their lifespan significantly.

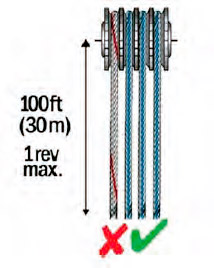

- To ensure proper installation without any torsion or twisting, the ropes should be checked for the number of rotations. The easiest way to check this is to observe the line painted along the ropes during one full trip. Stand in the machine room near the hoist machine and count the rope rotations. The number of rope rotations must not exceed one for about every 100 ft of rope length (Figures 8 and 9).

Hoist Rope Load Equalization

Although equal load tension on the hoist ropes is a code requirement, this is often not taken seriously enough and requires more attention from the industry. Equal load tension on ropes plays a crucial role in performance of the system, as well as in life expectancy of both ropes and sheaves. When there is uneven load on the hoist ropes, the rope that has to carry more of the load causes greater sheave groove wear and sits deeper in the groove. An unbalanced load reduces the life expectancy of both the ropes and sheaves. Meanwhile, the ropes carrying less of the load will slip over the sheave as a result of different speeds. This phenomenon reduces the performance and safety of the system, in addition to damaging the ropes and sheaves. To prevent such problems, rope tension should be equalized during installation/replacement, and be reviewed and adjusted regularly as part of a regular maintenance routine. Unequal hoist rope tension can be caused by several conditions:

- Missing or broken anti-rotation device

- Unequal rope stretches due to installation mistakes, such as twisting the ropes or insufficient time allowed for initial rope stretch

- Unequal sheave grooves when new ropes are installed on existing sheaves

- Rouge on hoist ropes, which, over time, changes the diameter of the rope and changes the sheave groove pattern

- Hoist rope vibration

There are different methods of rope tension measurement and equalization; while all methods have degrees of errors, newer tension devices are more reliable and faster to implement.

Using tension gauges and tensiometers is a common method of balancing rope tension (Figure 11). In this method, the technician should measure each rope’s tension repeatedly and use the results to balance the tension of all ropes. It is important that the location of the device be the same for all ropes during the process and that proper care is taken to reduce human error. Using this method can be challenging in more complicated arrangements, such as 2:1 roping.

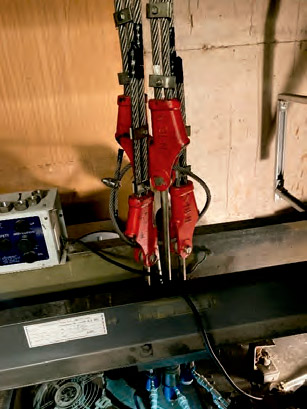

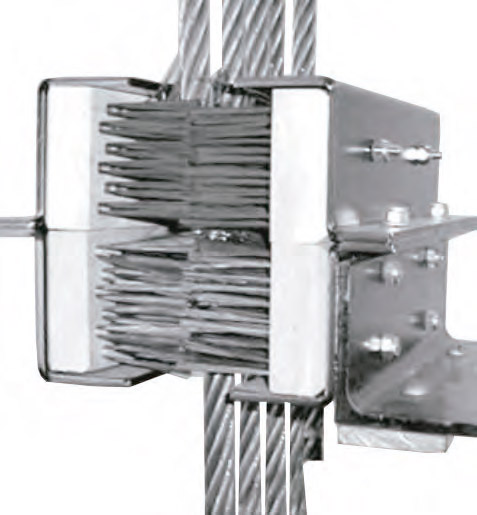

For better results, hydraulic tools that use hydraulic pressure to equalize rope tension help avoid flawed measurement and human error (Figure 12).

There are also automatic hydraulic rope tension equalizing devices. These devices are installed permanently at the endpoint of the hoist ropes, producing constant tension equalization of the ropes. These devices help to reduce the risk of error and cost of maintenance by working independently (Figure 13).

Lubrication

Lubrication is a key factor for greater rope longevity, and this process needs more attention and awareness. We all know that lubrication is essential to protect the rope against excessive friction within its strands, core and wires. Likewise, we know it protects ropes against moisture and corrosion. But, this very important issue is not always taken seriously and is surrounded by many misunderstandings.

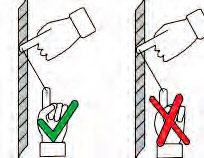

It is important to monitor the ropes’ condition regularly and lubricate them per the manufacturer’s instructions. A simple way to check the ropes for proper lubrication is to touch them.

A lubricated rope will leave a mark on the finger; if there is no mark, the ropes should be lubricated (Figure 14).

There are many improper methods of manual lubrication, such as pouring, dripping or swabbing oil onto the rope. Using a roller applicator is the best way to manually lubricate hoist ropes, but it is important to make sure the ropes are lubricated from both sides.

Rope tension should be equalized during installation/replacement, and be reviewed and adjusted regularly as part of a regular maintenance routine.

There are also automatic lubrication methods. In an automatic lubrication system, oil is applied to the rope through a felt strip via an electrostatic charge. The adjustment of the gap between the felt and rope is very important; an improperly adjusted and positioned device can damage the felt or result in not lubricating the ropes at all. Also, in many cases the oil reservoir runs empty as a result of poor maintenance. Another issue with automatic lubricating systems is they often create a false sense of trust that prompts the mechanic to overlook the status of the ropes’ lubrication. The elevator mechanic should always review and ensure proper operation of the automatic lubricator, as well as the condition of lubrication on the hoist ropes (Figure 15).

Too much lubrication can also be a problem, as this might reduce traction, attract dust and can even throw oil onto the machine and brake surfaces, causing a safety issue. It is important that ropes be cleaned in these cases, and when rope tar has developed on the hoist ropes. Installing a cleaner (scraper) o elevator ropes is an effective way to eliminate the need to clean the hoist ropes manually (Figure 16).

Another common mistake is when technicians apply extra lubrication on the ropes when there is rouge on them. Lubrication cannot restore ropes from rouge effects; in fact, this could worsen the condition by overlubricating and covering the rouge effects. Ropes should be replaced if there is rouge and other unfavorable conditions.

Conclusion

Hoist ropes are constantly under tension and subject to wear from friction, both internally between strands and externally with other components, like sheaves. This harsh working environment requires extra caution and attention to the ropes to ensure they are working properly and are in good condition. Proper lubrication, rope tension equalization and twisting prevention are mportant for smooth, safe operation of elevators. Current arguments about rope designs and quality notwithstanding, proper installation and maintenance are the most important aspects of extending the life of hoist ropes.

References

[1] ASME A17.1-2010/CSA B44-10

[2] Brugg Lifting User Reference Guide.

[3] Draka Rope Installation Guide.

[4] Schindler Elevator Installation and Maintenance Manual

[5] KONE Elevator MCP Manual

Get more of Elevator World. Sign up for our free e-newsletter.