How to Maximize the Value of Maintenance and Service Contracts Using the Internet of Things

Jul 1, 2021

In this Product Spotlight, your author introduces an AI product with the ability to help companies provide predictive maintenance.

The fourth industrial revolution has reached the elevator industry, and industry leaders are winning market share by investing in AI. AI helps decode the complex system landscape. Decades of continued rapid growth combined with equipment longevity have resulted in a wide variety of makes, models and vintages of elevator systems, and many independent providers are looking for ways to counter the widening technological capability gap.

As the global installed base of 16 million elevators continues to expand in size and complexity, adding extra manpower alone will not solve today’s challenges. The trend that will underpin the future of the elevator industry is, undoubtedly, the adoption of new technologies to radically alter the ever-growing maintenance and repair side of the industry. The ability to offer predictive maintenance is key to success.

Generating value is at the heart of modern digitalization movements. Added value can be unlocked by a well-considered deployment of the Industrial Internet of Things (IIoT). This also stands true for the elevator industry. Elevator service and maintenance companies can gain efficiency and enable new revenue streams by implementing digital tools and data diagnostics.

Unlocking the Power of IoT

As global demand for elevator equipment and services is on the rise, there is enormous potential for innovation in the elevator industry. Customers today expect faster service – minimal machine downtime has never been more critical to success, and market competition is steep. Equipment maintenance is at the core of a customer-centric approach, but providing a positive customer experience is not possible through only reactive maintenance.

Reactive maintenance leads to a vicious circle. When failures occur, there is an urgent need for unplanned repairs. Thus, planned maintenance is postponed, which ultimately leads to unplanned downtime and an increase in backlogs. Predicting failures is critical to avoiding unnecessary downtime. That’s why digitalization is so important for the elevator industry: enhancing performance, ensuring customer satisfaction and gaining a competitive edge are possible through connectivity and digital technologies.

The numbers speak for themselves. A study of the elevator market conducted by the global consultancy Roland Berger revealed that emerging technologies offer significant cost reduction potential and drive profitability. The introduction of predictive maintenance, for example, results in up to 14-19% less downtime and 5-10% cost savings on repairs.

The IIoT has the power to move the needle in the elevator industry. Reactive maintenance becomes a thing of the past, which leads to lower service costs. Additionally, improving operational efficiency is a guarantee for higher customer satisfaction.

The Challenge: Making Data Work for You

There are numerous reasons why legacy companies often resist implementing the new generation of IIoT solutions. Even if and when a company realizes the benefits of implementing IIoT, they may not be quick to decipher the benefit vs. drawback trade-off of IIoT. For example, upfront costs can be seen as a barrier to some companies unable or unwilling to estimate the longer-term savings that early IIoT investment can unlock.

On the other hand, simply having IIoT-ready sensors installed isn’t a guarantee of quality, usable data. So-called “garbage data” is a constant enemy of effective data analysis. The key here is to have the right IIoT partners on board who can offer solutions that minimize these risks. As the real power of IIoT lies in making sense of high-quality data, AI solutions can qualify a solid partner.

Ensuring RoI from the Very First Day

Utilizing cutting-edge data analysis leads to a lower number of callbacks and considerably shortens troubleshooting time. Not only that, unplanned service visits become plannable – independent maintenance and service providers can react to wear and tear in advance. Introducing remote diagnostics also means that planned visits are reduced. The power of data unlocks a wide array of opportunities; new revenue streams are another benefit of leveraging an IIoT solution. Advising customers on possible modernizations and optimizations not only results in higher customer satisfaction but leads to greater returns.

A Return-on-Investment (RoI) calculation can help assess if and when the desired improvements will exceed the value of the investment itself.

Elevator service providers build their profits (in comprehensive contract models) as the balance of costs to deliver the agreed terms and agreed contractual fee. Therefore, they face a complex “elevator-by-elevator” challenge to find the right balance between the effort they put in and the risk of component failure. Small service providers cannot afford to take that risk and therefore tend to have lower margins in the contract models than larger companies.

When investing in IoT-based elevator monitoring, for example, organizations need to assess if the annual costs for such an investment can deliver more value with cost savings and additional revenue.

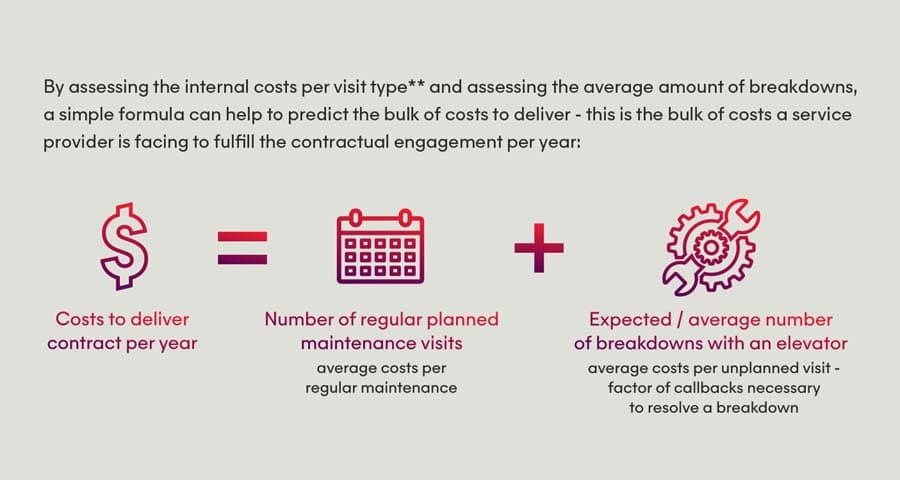

A service provider is facing only two major cost drivers to fulfill a comprehensive contract model: regular maintenance visits and unplanned visits.

By assessing the internal costs per visit type (costs for unplanned visits can be higher, often up to 50%, than regular maintenance visits) and assessing the average amount of breakdowns, a simple formula can help predict the bulk of costs to deliver: [Costs to deliver contract per year] = [Number of regular planned maintenance visits] x [Average costs per regular maintenance] + [expected/average number of breakdowns with an elevator] x [average costs per unplanned visit] x [factor of callbacks necessary to resolve a breakdown]. This is the bulk of costs a service provider is facing to fulfill the contractual engagement per year.

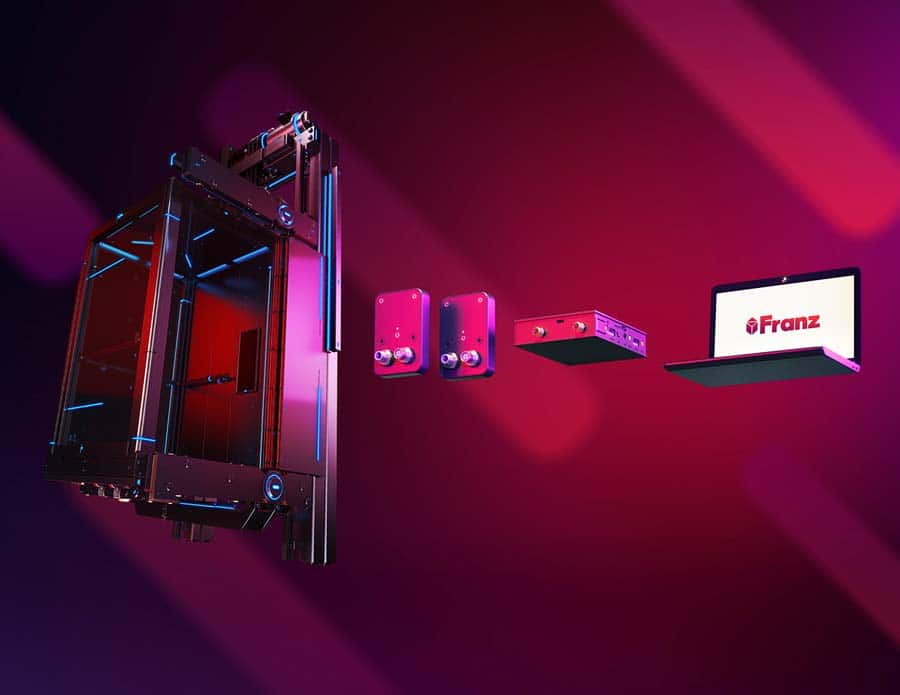

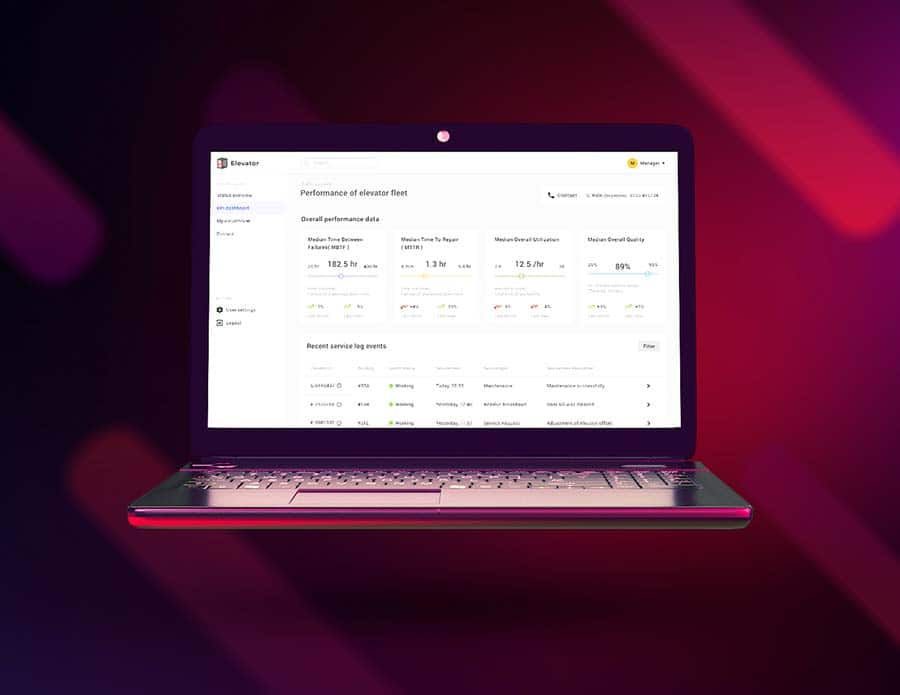

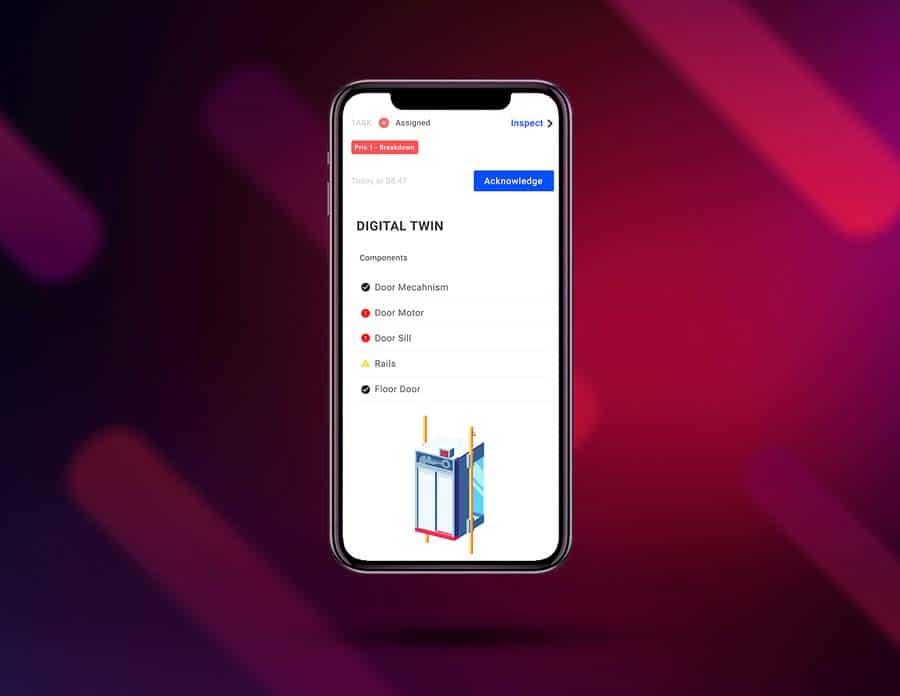

An investment in a smart elevator solution needs to address these costs with increasing operational efficiency or add additional revenue/business opportunities. Solutions like Franz (exclusively available in North America) are designed to specifically address the factor of callbacks necessary to resolve a breakdown by providing root cause information and guidance to the components that failed or showed signs of failure. As Franz also comes with 24/7 monitoring, it can reduce the number of regular visits, and more importantly, collects performance-based data. This data can be offered to the end-customer through a customized portal operated by the service provider. Industry studies revealed that medium to large operators are willing to pay an additional 10-20% of the annual service contract value for these insights.

Thus, service providers are able to reduce costs to fulfill their contracts and can gain additional revenue.

At hellofranz.com, you can try the RoI calculator and determine the return on investment for your service company.

Get more of Elevator World. Sign up for our free e-newsletter.