Rules and regulations regarding escalator drive chains and how to maintain them

Each mechanical piece of an escalator can withstand a certain amount of pressure and stretch. If more than that amount is applied to the desired part, it will break, fracture, tear, bend, etc. This article investigates rules and regulations regarding escalator drive chains.

For better maintenance of the engine’s chain, we must observe the rules:

- The engine chains, sprockets and gearbox outputs must always be aligned in the same direction. Otherwise, the sprocket and gearbox will wear prematurely, and the chain will be damaged.

- The chain is due to rotate around a constant axis and should be steadily lubricated for optimum performance. This can be done manually or automatically.

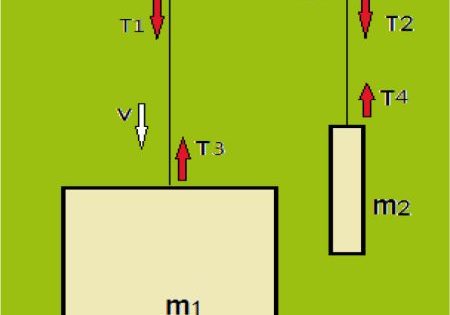

- The chain must have slackness when connected to the gearbox output to prevent pressure on the motor and chain itself. For most models, this measurement on the sprocket must be 30 mm, combined, from the top and/or bottom of the chains. Movement will be affected if this measurement is less or more.

If the loop is loose, there may be a risk of collision with the engine chip breakage microswitch, resulting in frequent static outages. If the engine chains are tight, too much pressure may be applied to the chain, sprocket and motor, causing engine overheating and, in some cases, a break in the main axis.

Signs the chain is loose include:

- The sound of the chain continuously encountering the pad

- Frequent escalator stoppages due to the chain activating the safety switch. The programmable logic controller will power off the escalator. If passengers are present, they may lose balance due to the abrupt stop if the brake mechanism isn’t set.

- A “heartbeat” (rotational) motion as the escalator moves downward

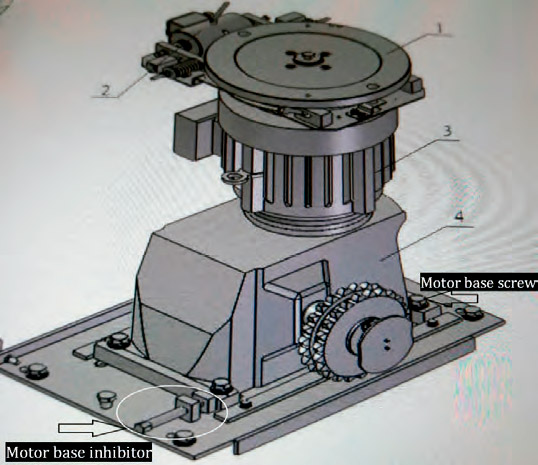

To set the motor base when not setting the chain, first, put the chain in the middle. Then, loosen the four screws of the base of the motor to adjust.

Next, depending on the stiffness or looseness of the chain, change the engine’s base position. If the engine chain is loose, tighten the motor locking screw to tighten the chain. If the chain is tight, loosen the motor locking screws, and use a lever to drive the motor forward to loosen the chain.

Before tightening the screws, measure the motor base’s position relative to a constant source using a ruler to ensure the base is aligned with other parts. Keep in mind that the motor base screws should be tightened in a cross-section using a torque wrench, and do not forget that the motor locking screw must also be tightened using a torque wrench to prevent unintentional movement of the escalator.

After adjusting the motor base and the chain, move the escalator once in both directions to ensure the desired performance of the engine chains.

Get more of Elevator World. Sign up for our free e-newsletter.