In this Product Spotlight, a new pit safety system is explained.

Electronic Controls, Inc. (ECI America) has developed a new elevator pit safety system appropriately named “PitSafe®.” The design of this product was centered around available data on injuries and deaths occurring in elevator pits. Statistics indicate that a percentage of these injuries and deaths affected individuals seeking access beneath the elevator to retrieve fallen items, such as cell phones, keys, etc. It was noted in these occurrences that proper safety protocols were not followed. These accidents involved individuals who were authorized or educated in elevator safety matters, as well as those not authorized to enter the pit. Although there were other noted causes of pit accidents, such as equipment failure and/or environmental hazards, the all-too-common theme was a failure to follow elevator safety practices.

ECI research determined three common causes of elevator pit accidents:

- Accessing the pit without taking the elevator out of service

- Human error, distractions and not following safety protocols

- Defective components or equipment failure

In identifying these causes, the company vowed to bring a product forth to eliminate these accidents.

Although there were other noted causes of pit accidents, such as equipment failure and/or environmental hazards, the all-too-common theme was a failure to follow elevator safety practices.

Safety by Design – The Problem and The Solution

Problem: Individuals seeking access into the pit would turn on the lights but not take the elevator out of service, due to lack of knowledge or human error.

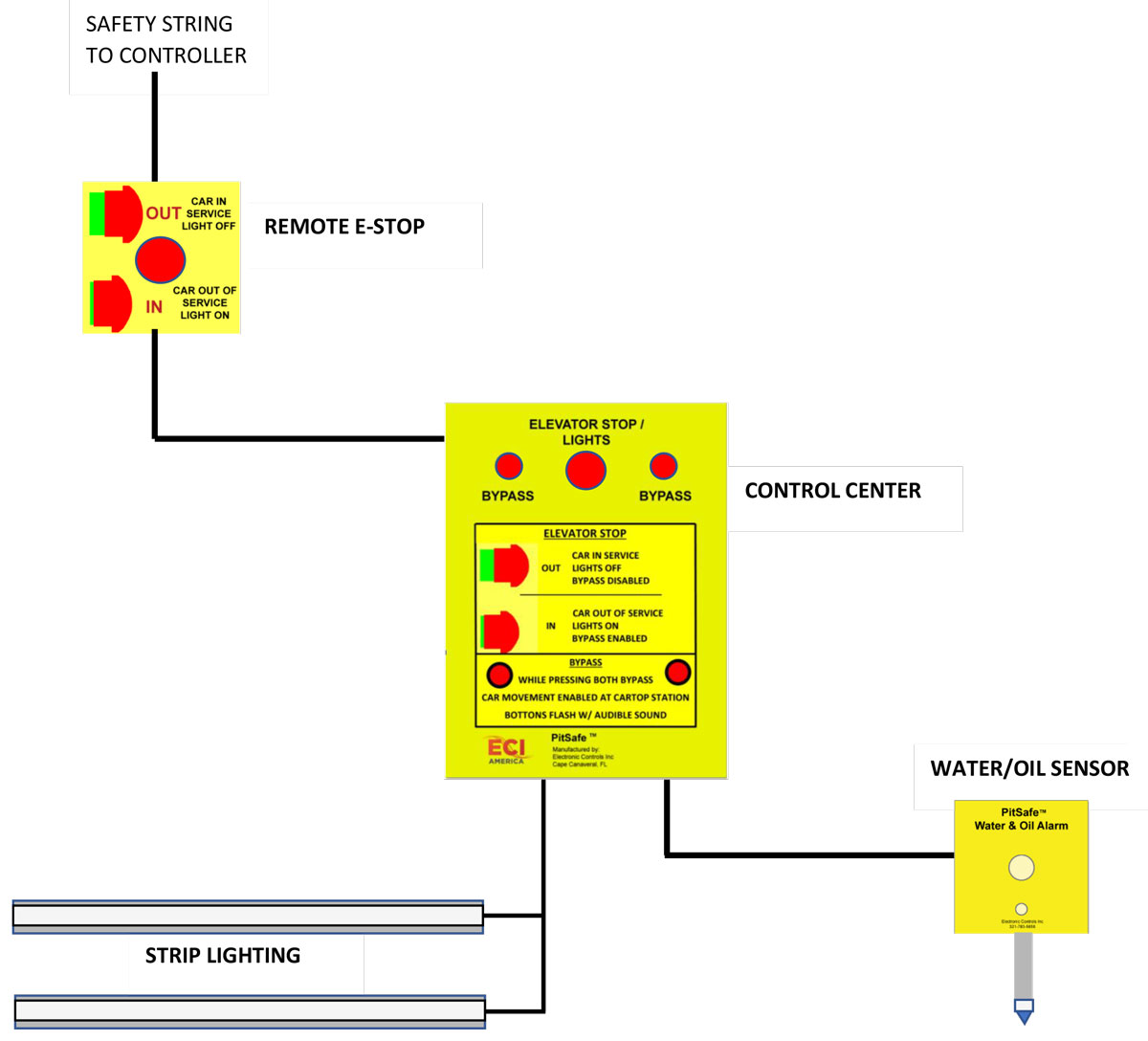

The PitSafe Solution: The pit lights and pit stop switch must operate simultaneously. This single concept virtually eliminates anyone from entering the pit without taking the elevator out of service. ECI incorporates a dual activating single fail-safe push button switch within a NEMA 4 enclosure properly labeled and identified.

Problem: Human error, cell phones and other distractions, not following safety protocols.

The PitSafe Solution: The pit lights and pit stop switch operate simultaneously, virtually eliminating anyone from entering the pit without taking the elevator out of service. Additionally, safety is put in control of the mechanic in harm’s way while in the pit, giving them the ability to control movement and access to the car by others located outside of the pit.

Problem: Defective components, equipment failure, poor lighting.

The PitSafe Solution: Only use fail-safe push pull switches with the implementation of fail-safe circuitry to protect override buttons so in the event of a single component failure the device will fail-safe taking the elevator out of service.

Problem: Lightingis probably the most overlooked item in elevator safety, although it is a recognized hazard and code requirement. Pits are notoriously dark spaces with notably poor lighting.

To further the issue, many lights are found not working during inspections as, they were previously left on or burned-out, with most pit lighting arrangements not able to meet code.

The PitSafe Solution: Provides two CabLite® Roughneck 4-in. LED Strip lights, guaranteed to meet elevator code requirements and providing maintenance free lighting for more than 10 years. ECI further identified optimal placement of the two light strips, with one being vertical and one horizontal, on adjoining walls for optimum pit illumination. Additionally, the PitSafe solution incorporated emergency lighting battery backup to keep these lights on for safe egress from the pit in the event of a power failure.

Problem: Water/oil in the pit is an environmental hazard that can occur when there is oily water in the shaft as a result of water coming into contact with hydraulic fluids and/or lubricants used in the elevator. In addition, elevator pits are subject to flooding during inclement weather situations.

The PitSafe Solution: The device provides a solid-state oil/water sensor with audible alarm and a flood water signaling connection to allow a programmed elevator controller to disallow movement to a bottom floor in the event of water detection.

The PitSafe pit maintenance system encompasses all the necessary components for a complete installation (see Figure 1).

The only electrical requirement is for a dedicated 115 VAC outlet on new installations. All electrical requirements should already exist on modernization projects, allowing conveyance licensed elevator mechanics the ability to install all the components in the pit.

PitSafe is not a device that eliminates proper safety practices in taking control of a car to gain access to the pit or from following lockout/tagout procedures when performing maintenance.

Get more of Elevator World. Sign up for our free e-newsletter.