Innovative Escalator Modernization at Sants Station

Mar 1, 2015

ThyssenKrupp Elevadores installs first iMods in Europe.

Approximately seven years ago, ThyssenKrupp Elevadores, Spain began working with the Transports Metropolitans Barcelona (TMB) on a project to replace 56 old escalators at Sants Station, the main intermodal transit station in Barcelona. With an annual passenger volume of close to 30 million, Sants Station connects to several Barcelona metro, national railway (Renfe Operadora), high-speed train (AVE) and long-distance coach stations. Unfortunately, Line 5 of the Barcelona metro presented a problem that stymied this project: Sants’ number one escalator, nicknamed “Revenge,” was extremely difficult to access, because it was sandwiched between two walls. It was, accordingly, excluded from the initial project.

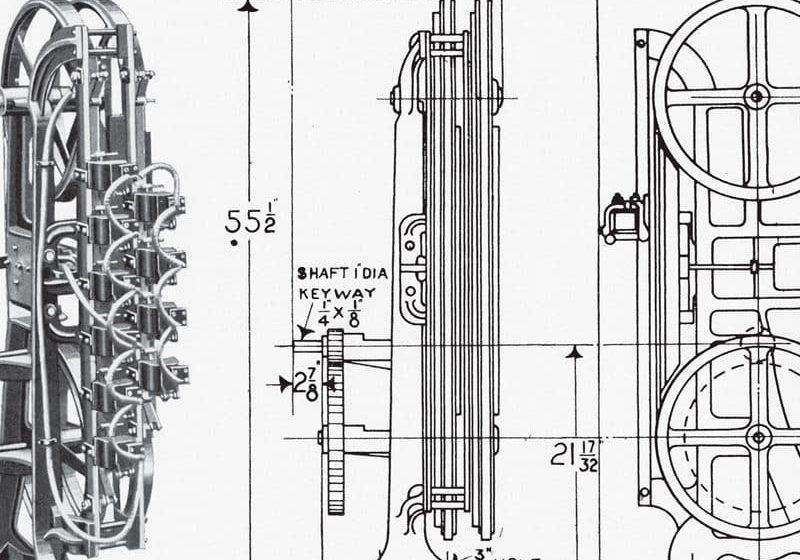

But, then, ThyssenKrupp Norte launched the iMod escalator model. Having been successfully used on reference jobs in the U.S., the iMod is ideal for remodeling inaccessible escalators due to architectural constraints that make it difficult to install conventional 6-m-long sections. It overcomes this obstacle by installing modules manufactured to fit the existing escalator structure.

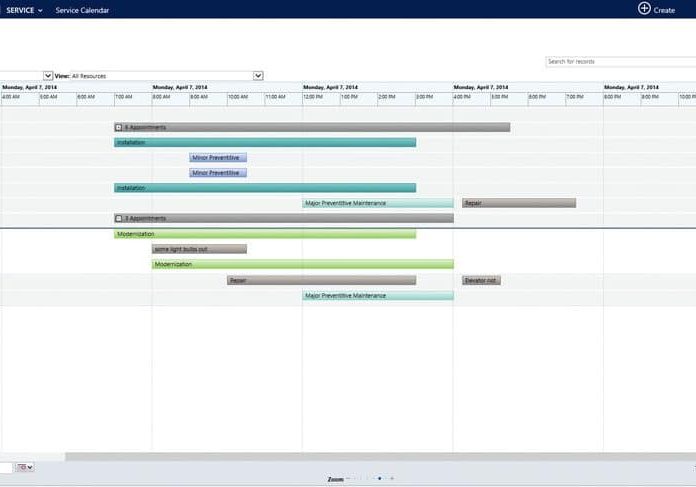

With this technology in its arsenal, ThyssenKrupp Elevadores would have its own revenge four years after the initial project. The company revisited the project with TMB, and a plan for seven escalators was drafted. Despite economic difficulties, Barcelona Metro decided to call for tenders on the works, and a contract was signed to install three iMods in the Sants Station on Line 5 of the metro.

Project manager Javier Mur Ruiz de Mendoza oversaw the modernization of the iMods at Sants Station. He has been leading some of the most challenging projects ThyssenKrupp Elevadores has faced in the past seven years: Intxaurrondo Station, L1-L4-L5-L9 Metro Barcelona, the Arts Hotel renovation, urban accessibility in Santa Coloma and Portugalete, Girona and AVE – to name just a few of the latest examples.

Besides the usual difficulties, the work environment further complicated this project. Since Sants Station is very busy, TMB only allowed ThyssenKrupp Elevadores to work in shifts of six hours at night during the summer season. However, the installation went as planned, made possible due to the fact that ThyssenKrupp Elevadores has personnel specializing in unique installations, as well as its own factory in Spain.

The project was concluded on April 11, 2014, when the iMods were put into operation. These are the first of their kind in Europe, and this is the first time ThyssenKrupp Elevadores has used this method for the complete remodeling of an escalator.

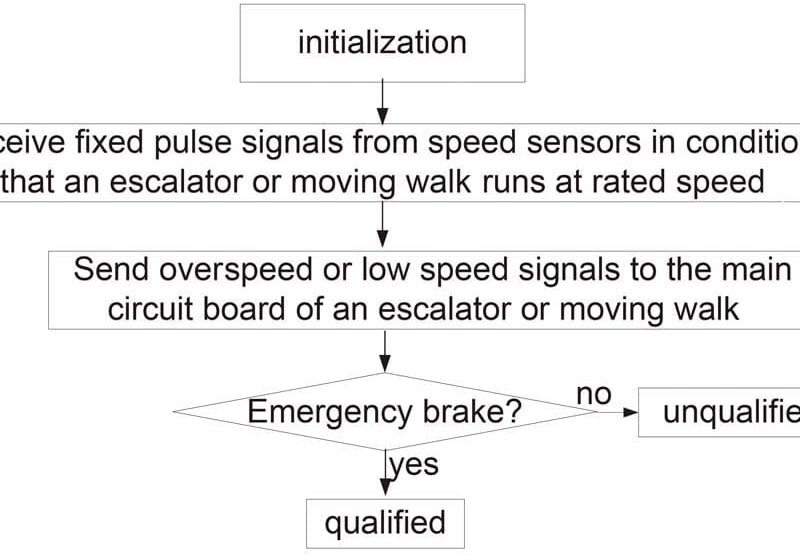

Process of Assembling an iMod

- The old escalator is completely scrapped, keeping only the structure.

- The existing structure is repaired, cleaned and painted.

- The structure is officially approved to ensure it will withstand the loads to which it will be subjected.

- The upper and lower modules, which are the largest parts of the assembly, are installed.

- Intermediate elements are fitted.

- Installation of mechanical and electrical components are completed.

- Stainless-steel cladding is placed.

- Performance tests are done to give the final OK.

Get more of Elevator World. Sign up for our free e-newsletter.